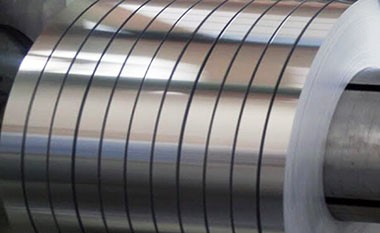

3003 Double Cladded Aluminum Brazing Alloys Strip for Radiator Condenser Evaporator

The 3003 double-clad aluminum brazing alloy strip is a composite material, typically made with 3003 aluminum alloy as the inner layer and an aluminum alloy with excellent brazing properties (such as 4045 or 4343 aluminum alloy) as the outer layer. This material is widely used in heat exchange equipment such as radiators, condensers, and evaporators, offering excellent heat exchange performance, corrosion resistance, and brazing properties. It is one of the key materials in modern thermal exchange systems.

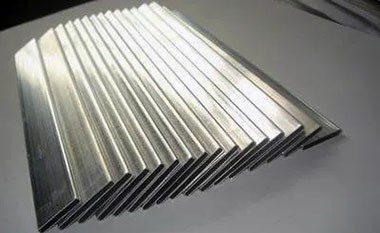

Structure of 3003 Double Cladded Aluminum Brazing Alloys Strip

Inner Core Material: 3003 Aluminum Alloy

Composition and Properties: 3003 aluminum alloy is primarily composed of aluminum and about 1% manganese, offering excellent corrosion resistance, relatively high compressive strength, and outstanding formability. Its corrosion resistance is especially prominent in high-temperature and humid environments, making it suitable for long-term exposure to condensate, moisture, or chemical media.

Function: The 3003 aluminum alloy in the inner layer supports the internal structure and strength of heat exchangers. It can withstand high temperature and pressure variations, making it especially suitable for use in the inner tubes or other pressure-bearing components of condensers and evaporators.

Outer Layer: Brazing Alloy (e.g., 4045 or 4343 Aluminum Alloy)

4045 Aluminum Alloy: 4045 aluminum alloy has a relatively high silicon content (9-12%), which gives it a lower melting point during brazing, allowing it to form a stable bond with the brazing filler metal, ensuring strong and durable joints. The outer layer of 4045 aluminum alloy also provides excellent corrosion resistance, protecting the heat exchanger from external environmental influences.

4343 Aluminum Alloy: 4343 aluminum alloy also has a high silicon content, making it particularly suitable for applications requiring high brazing performance and corrosion resistance. It is commonly used in automotive, air conditioning, and refrigeration equipment such as radiators and condensers.

Specification of 3003 Double Cladded Aluminum Brazing Alloys Strip

- 1.Alloy states: 4343/3003/4343 4045/3003/4045

- 2.Temper:H O

3003 Double Cladded Aluminum Brazing Alloy Date Sheet

| Brazing Alloys | Width(mm) | Thickness(mm) | Length(mm) | Inside Dia(mm) |

| Aluminum Sheet | 500-1250 | 0.5-4.0 | 500-2500 | - |

| Aluminum Strip | 12-1250 | 0.2-4.0 | - | 150,200,250,300,400,500 |

| Aluminum Foil | 12-1200 | 0.05-0.2 | - | 150,200,250,300,400,500 |

| Clad Ratio | 4-18% per side | |

| Percent Clad(per side) | 4-8% | >8-18% |

| Clad ratio tolerance | ±1.5% | ±2.0% |

Applications of 3003 Double Cladded Aluminum Brazing Alloys Strip

3003 Double Cladded Aluminum for Radiators

Automotive radiators, air conditioning radiators, etc.: The 3003 double-clad aluminum brazing alloy strip is widely used in automotive radiators, air conditioning radiators, and industrial cooling systems due to its excellent thermal conductivity and good corrosion resistance. The outer layer brazing alloy provides excellent brazing performance, ensuring a long-term stable operation of the radiator under high temperature and high-pressure conditions.

Improving Heat Exchange Efficiency: Due to the good thermal conductivity of the aluminum alloy itself, the 3003 double-clad aluminum brazing alloy strip can effectively improve heat exchange efficiency, helping to dissipate heat quickly and prevent overheating of the equipment.

3003 Double Cladded Aluminum for Condensers

Air conditioning, refrigeration equipment: In condensers, the outer layer (such as 4045 or 4343) of the 3003 double-clad aluminum brazing alloy strip provides good brazing performance, ensuring that the connections between condenser components are strong and durable. The inner 3003 aluminum alloy can withstand corrosion from condensate and high-pressure environments, ensuring the stability of the condenser during prolonged operation.

Corrosion Resistance: Condensers are often exposed to corrosive environments such as water vapor, chemicals, and humidity. The inner layer of 3003 aluminum alloy has excellent corrosion resistance, extending the lifespan of the condenser.

3003 Double Cladded Aluminum for Evaporators

Air conditioning systems and refrigeration equipment: The 3003 double-clad aluminum brazing alloy strip is widely used in the manufacturing of evaporators, especially in air conditioning and refrigeration systems. The outer brazing alloy layer provides high-quality welded joints, ensuring the sealing and structural strength of the evaporator during operation.

Improving Operational Efficiency: Due to its excellent thermal conductivity, the 3003 double-clad aluminum brazing alloy strip can effectively enhance the heat exchange efficiency of the evaporator, reducing energy consumption and improving overall equipment performance.

Advantages of 3003 Double Cladded Aluminum Brazing Alloys Strip

Excellent Brazing Performance

The outer layer of aluminum alloy (such as 4045 or 4343) has good brazing properties, allowing it to form strong bonds with brazing filler metals at high temperatures, ensuring the strength and sealing of joints. After brazing, the connection between aluminum alloy materials is very strong, able to withstand prolonged high-temperature and high-pressure working conditions.

Superior Corrosion Resistance

The inner 3003 aluminum alloy offers outstanding corrosion resistance, especially in humid, marine climates or chemical environments, maintaining stability. Therefore, 3003 double-clad aluminum brazing alloy strips are ideal for heat exchangers, condensers, evaporators, and other equipment exposed to such environments over long periods.

Improved Heat Exchange Efficiency

The good thermal conductivity of aluminum alloys allows the 3003 double-clad aluminum brazing alloy strip to effectively improve the heat exchange efficiency of heat exchangers, optimize thermal management, and ensure efficient operation of the equipment even with low temperature differences.

Resistance to High Pressure and Temperature Variations

The 3003 double-clad aluminum brazing alloy strip can withstand the common temperature and pressure variations in equipment, ensuring that heat exchangers, condensers, and evaporators maintain stable performance in changing environments, preventing structural damage due to thermal expansion or pressure fluctuations.

Extended Equipment Lifespan

Due to its excellent corrosion resistance and brazing properties, equipment such as heat exchangers, radiators, condensers, and evaporators made using the 3003 double-clad aluminum brazing alloy strip demonstrates high reliability and durability over long periods of use.

The 3003 double-clad aluminum brazing alloy strip is an excellent composite material, widely used in heat exchangers like radiators, condensers, and evaporators. It combines the corrosion resistance of 3003 aluminum alloy with the superior brazing properties of outer aluminum alloys (such as 4045 or 4343), as well as good thermal conductivity, making it an ideal thermal exchange material in modern industries like air conditioning, refrigeration, and automotive sectors. This material not only improves the heat exchange efficiency of equipment but also extends its service life, playing a key role in achieving efficient and stable thermal management.

Maybe also you like: