Brazing Aluminum Strip for automotive air conditioning evaporator

The automotive air conditioning evaporator is an essential component in the automotive air conditioning system, primarily responsible for absorbing heat from inside the vehicle, thereby lowering the interior temperature and enhancing passenger comfort.

The brazing aluminum strip used in automotive air conditioning evaporators is specially designed for automotive air conditioning systems, offering excellent thermal conductivity, corrosion resistance, and weldability, making it suitable for high-temperature, high-pressure environments.

Brazing Aluminum Strip Material Properties

Advantages of aluminum: Aluminum has excellent thermal conductivity and corrosion resistance, is lightweight, and has high strength, making it ideal for use in automotive air conditioning systems. The high thermal conductivity of aluminum allows the evaporator to quickly and effectively absorb heat.

Brazing alloy: The brazing aluminum strip is typically made from aluminum alloys, with appropriate amounts of alloying elements (such as silicon, magnesium, etc.) to enhance its welding performance and corrosion resistance.

The brazing aluminum strip used in automotive air conditioning evaporators is typically made from silicon-containing aluminum alloys (such as 4045, 4343, 3003, etc.).

- 4045 Aluminum Alloy: Known for its higher silicon content, this alloy is suitable for high-strength and excellent brazing applications. It offers good weldability and superior mechanical performance at high temperatures.

- 4343 Aluminum Alloy: Used in air conditioning systems, it has good thermal conductivity and corrosion resistance, and is commonly used in the manufacturing of aluminum automotive air conditioning evaporators.

- 3003 Aluminum Alloy: This alloy has good corrosion resistance and workability, and is commonly used for the tubing and external structural components of the evaporator.

Brazing Aluminum Strip Suppliers

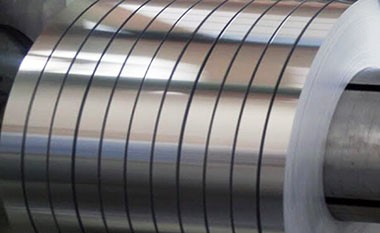

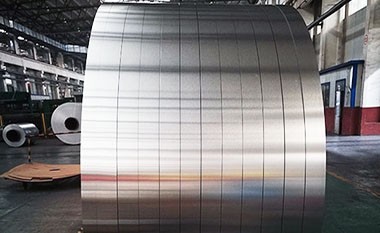

HC Aluminum is a professional manufacturer and supplier of brazing aluminum strips. Our brazing strips are made from hot-rolled composite sheets, which undergo multiple rolling processes, with the core layer and composite layer firmly bonded together, ensuring excellent performance in brazing and heat exchange.

- Grade: 3003(+Zn), 3Z19, 4045, 4343, 7072

- Thickness: 0.20mm – 5.0mm

- Width: 20-1600mm max.

Brazing aluminum strips are widely used in automotive heat exchangers, evaporators, condensers, oil coolers, air conditioners, household air conditioning radiators, and more.

HC Aluminum is a professional manufacturer and supplier of brazing aluminum strips, offering high-quality products at competitive prices. If you would like to learn more about our brazing aluminum strip products or brazing aluminum foil, please feel free to contact us. We will respond within 24 hours.

We also supply aluminum composite high-frequency welded tubes, hydrophilic aluminum foil, and aluminum parallel flow microchannel flat tubes.

| Product | Description |

| Clad Tube | Tube products designed for both welded and folded tube configurations, supporting trends in reducing material thickness while meeting higher requirements for corrosion resistance, brazeability, and strength. |

| Clad Fin | Developed to provide excellent brazeability, resistance to core dissolution, and high-temperature endurance. Allows for reduced material thickness to produce lighter heat exchangers. |

| Unclad Fin | The simplest heat exchanger material, consisting of a single alloy without clad layers. Commonly used in radiators, heaters, charge air coolers, and evaporators. |

| Clad Plate | A core alloy clad with braze material on one or both sides. The rolled product is stamped or shaped by the customer according to the application and is used in various heat exchanger applications, including coolant plates and manifolds. |

Brazing Aluminum Strip Technical Information

| Product Name | Description | Core Layer Alloy | Blazing Layer Alloy | Water-contact Side Alloy | Temper | Application | Thickness (mm) |

| HC807 | 3003/4343/7072 | 3003 | 4343 | 7072 | H14 | Tube | 0.2-0.4 |

| HC808 | 3003+Cu/4343/7072 | 3003+Cu | 4343 | 7072 | H14 | Tube | 0.2-0.4 |

| HC809 | 3003/4045 | 3003 | 4045 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC811 | 3Z01/4343 | 3Z01 | 4343 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC812 | 3Z12/4343 | 3Z12 | 4343 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC814 | 3Z22/4343 | 3Z22 | 4343 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC815 | 3Z22/4343 | 3Z22 | 4343 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC816 | 3Z22/4343/7072 | 3Z22 | 4343 | 7072 | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC817 | 3Z22/4045/7072 | 3Z22 | 4045 | 7072 | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC818 | 3Z23/4343 | 3Z23 | 4343 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC801 | 3003/4343 (Single cladding) | 3003 | 4343 (Single cladding) | / | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC802 | 3003/4343 (Double cladding) | 3003 | 4343 (Double cladding) | / | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC807 | 3003/4343/7072 | 3003 | 4343 | 7072 | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC808 | 3003+Cu/4343/7072 | 3003+Cu | 4343 | 7072 | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC810 | 3003+Cu/4045/7072 | 3003+Cu | 4045 | 7072 | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

Brazing Aluminum Strip Properties

- Weldability: Brazing aluminum strips are designed specifically for the brazing process, offering good weldability, allowing reliable connections with other aluminum materials during brazing, and forming strong joints.

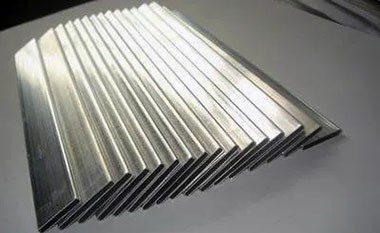

- Bendability: The aluminum strip has good plasticity, allowing it to be bent and stretched during the forming process to meet different design requirements.

- Surface Treatment: The surface of brazing aluminum strips is typically subjected to oxidation treatment or coated with welding flux to enhance weldability and improve corrosion resistance in the final product.

- Excellent Thermal Conductivity: The thermal conductivity of the aluminum strip directly affects the cooling efficiency of the evaporator, requiring a high thermal conductivity.

- Corrosion Resistance: As refrigerants are used in air conditioning systems, the aluminum strip must have excellent corrosion resistance to prevent corrosion in humid environments.

- Mechanical Strength: The aluminum strip needs to withstand certain pressures and temperature fluctuations during operation, so it must possess sufficient mechanical strength.

Brazing Aluminum Strip in Automotive Air Conditioning Applications

Automotive air conditioning systems are mainly used in the car's air conditioning evaporator, which absorbs heat from the air inside the vehicle and transfers it to the refrigerant.

- Evaporator Manufacturing: Brazing aluminum strips are primarily used in the manufacturing of key components of automotive air conditioning evaporators, especially in the connection of aluminum tubes and fins. The evaporator's function is to absorb heat from the air inside the vehicle through the refrigerant to achieve cooling. Brazing aluminum strips ensure the heat exchange efficiency and long-term stability of the components.

- Air Conditioning Pipelines: Brazing aluminum strips are also widely used in the manufacture of pipes within the air conditioning system due to their excellent connectivity and ability to prevent leakage issues.

Other Refrigeration Equipment: In addition to automotive applications, brazing aluminum strips are also widely used in the evaporators and condensers of other refrigeration and air conditioning equipment.

Brazing Aluminum Strip Manufacturing Process

Brazing Process: Brazing is the process of joining two or more metal parts by heating and filling with a metal material (brazing filler). During the manufacturing of the evaporator, aluminum strips typically undergo steps like pretreatment, cleaning, heating, and filler material application to ensure strong and leak-proof welded joints.

Surface Treatment: Before brazing, the surface of the aluminum strip must be treated to remove oxide layers and impurities to ensure the quality of the weld.

Automotive air conditioning evaporator brazing aluminum strips, with their excellent thermal conductivity, corrosion resistance, and good weldability, have become an indispensable material in automotive air conditioning systems. They not only improve the cooling efficiency of the system but also extend its service life.

Maybe also you like: