What is the difference between aluminum square tube and aluminum profile?

Aluminum square tube and aluminum profile are two common types of aluminum materials. While both belong to the category of aluminum profiles, they differ significantly in application fields, shapes, processing methods, and connection methods.

Comparison table between aluminum square tube and aluminum profile

| Category | Aluminum square tube | Aluminum profile |

| Application fields | Mostly used in architectural decoration, such as ceilings, airports, high-speed rail stations, shopping malls, etc. | Widely used in automation machinery, electronic devices, industrial equipment, transportation vehicles, etc. |

| Common alloys | Mainly Al-Mg-Si series alloys (e.g., 6063 aluminum alloy) | Various alloys (e.g., 6061, 6063, 7075, etc.), selectable based on requirements |

| Shape and cross-section | Mainly square, rectangular, commonly U-shaped, groove-type, etc. | Can form various shapes such as T-shaped, L-shaped, U-shaped, rectangular, etc. |

| Strength | Medium strength, suitable for decorative and general structural applications | High strength, suitable for mechanical, structural, and industrial applications |

| Surface treatment | Can be anodized, electrophoretically coated, etc., to enhance corrosion resistance and aesthetics | Can be anodized, electrophoresed, sprayed, etc., to meet various industrial requirements |

| Connection methods | Primarily uses keel installation systems (snap-on, flat teeth, etc.) | Primarily uses specialized accessories (corner connectors, bolts, T-nuts, etc.) |

| Used accessories | Fewer connecting accessories, mainly keels, snap-ons, etc. | A wide variety of accessories, including corner connectors, connecting grooves, bolts, etc. |

| Installation method | Simple, usually used for decoration and ceiling structures | More flexible, suitable for complex industrial structures and equipment installation |

Differences in the Applications of Aluminum Square Tube and Aluminum Profile

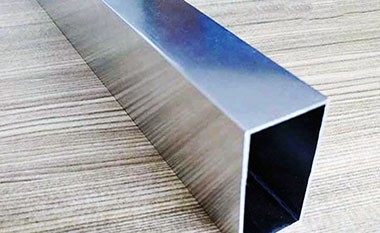

Aluminum square tube:

Application scenarios: Aluminum square tubes are mainly used in architectural decoration, especially in large public places such as airports, high-speed rail stations, shopping malls, office buildings, etc., often used for ceilings, decorative strips, and more.

Features: Aluminum square tubes have good plasticity and corrosion resistance, making them suitable for places requiring high appearance and durability.

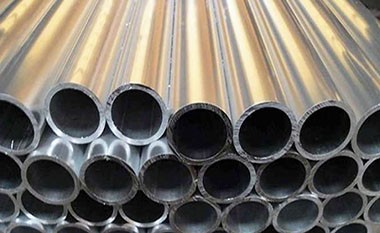

Application scenarios: Aluminum profiles are widely used in the automation machinery industry, electronic devices, furniture manufacturing, transportation vehicles, and industrial equipment. Common applications include electronic assembly line workbenches, factory workshop workbenches, machinery equipment protective covers, safety fences, automation robots, etc.

Features: Aluminum profiles offer flexible shapes and high strength, making them suitable for a variety of mechanical, industrial, and structural applications.

Differences in the Shape and Cross-section of Aluminum Square Tube and Aluminum Profile

Aluminum square tube:

Cross-section: Aluminum square tubes generally have a square or rectangular cross-section, with common designs such as U-shaped, groove-type, and more. They have higher hardness, good ventilation, and air permeability, commonly used for decorative and structural functions.

Manufacturing method: Aluminum square tubes are made by extruding aluminum plates or profiles, usually with a certain decorative quality, and are often used for simpler structural installations.

Aluminum profile:

Cross-section: Aluminum profiles can be extruded into various cross-sectional shapes, such as T-shaped, L-shaped, U-shaped, rectangular, etc. The specifications and sizes are highly diverse, capable of meeting the needs of different industrial and mechanical applications.

Manufacturing method: Aluminum profiles have flexible shapes and sizes, which can be customized and processed according to customer requirements, suitable for more complex and detailed structural designs.

Strength and Applicability of Aluminum Square Tube and Aluminum Profile

Aluminum square tube:

Strength: Aluminum square tubes generally use medium-strength aluminum alloys, such as Al-Mg-Si series alloys (e.g., 6063 aluminum alloy), which offer good plasticity and excellent corrosion resistance. However, compared to aluminum profiles, their strength is slightly lower. They are mainly used in places requiring strong decorative features and basic structural strength.

Surface treatment: Aluminum square tubes can undergo surface treatments such as anodizing and electrophoretic coating to enhance corrosion resistance and aesthetics.

Aluminum profile:

Strength: Aluminum profiles come in a variety of materials (e.g., 6061, 6063, 7075, etc.), allowing for the selection of different strength aluminum alloys according to requirements. They are suitable for industrial applications requiring higher strength, especially in mechanical and construction structures.

Surface treatment: Surface treatment methods for aluminum profiles include anodizing, electrophoresis, spraying, and more, which can better meet the needs of various industrial sectors.

Differences in Installation Methods and Accessories of Aluminum Square Tube and Aluminum Profile

Aluminum square tube:

Connection method: The installation of aluminum square tubes typically uses keel installation systems, with options such as snap-on, flat teeth, and multifunctional keels. Since aluminum square tubes are mostly used for ceilings and decorative applications, their connection methods are relatively simple, focusing primarily on decoration and aesthetics.

Accessories: Aluminum square tubes usually come with simple connection accessories such as keels and snap-ons for installation.

Aluminum profile:

Connection method: The installation of aluminum profiles is more flexible and complex. It typically requires specialized aluminum profile connection accessories, such as corner connectors, T-nuts, connecting grooves, bolts, washers, etc. Aluminum profiles are commonly used in structural installations, so their connection methods are diverse and can meet various industrial needs.

Accessories: Aluminum profiles have a wide variety of accessories, supporting multiple installation methods, and are suitable for different industrial structure installations and equipment configurations.

Differences in Industrial Aluminum Profile Accessories

Aluminum square tube:

Aluminum square tubes generally require fewer accessories for installation. The accessories typically focus on support and decoration. Connection accessories are mostly keels, snap-ons, etc., used for simple connections in ceilings and structural components.

Aluminum profile:

Aluminum profiles often require multiple accessories for assembly in industrial applications. The variety of accessories meets different installation needs, particularly suitable for automation, machinery equipment, construction, and frame structures, as well as complex installation requirements.

The main differences between aluminum square tubes and aluminum profiles are reflected in their material usage, shape and cross-section, strength, installation methods, and accessories. Aluminum square tubes are primarily used in decorative and architectural fields, offering high decorative functionality, while aluminum profiles focus more on industrial applications, especially in machinery and automation equipment. Selecting the appropriate material and connection method based on specific requirements can improve efficiency and meet design needs.

Maybe also you like: