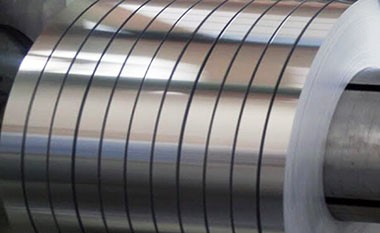

Double clad brazing aluminum strip for Air Conditioning Systems

The double-clad brazing aluminum strip for air conditioning systems is primarily used in the heat exchanger parts of air conditioning and refrigeration equipment, particularly in the manufacturing of evaporators, condensers, and heat exchangers. This aluminum strip typically offers excellent weldability, strength, and corrosion resistance to ensure the efficient operation and long-term stability of the air conditioning system.

Double Clad Brazing Aluminum Strip Specifications

The double-clad brazing strip consists of a core alloy, with one or both sides coated with a low-melting-point aluminum-silicon (Al-Si) alloy. This thin layer typically accounts for 5% to 10% of the total thickness of the brazing strip.

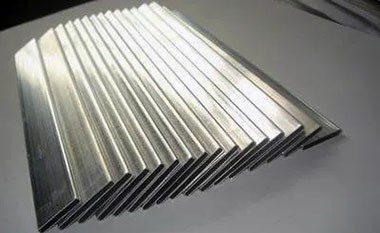

- Common aluminum brazing strip widths, thicknesses, and lengths can be customized according to customer requirements.

- Common alloy types include 3003, 4343, 4045, etc. The specific alloy composition and coating selection depend on the operating environment and requirements of the air conditioning system.

The brazing composite alloys typically come from the AA 4xxx series, or more specifically, AA 4343 (Al-6.8~8.2 wt.% Si).

If larger fillet radii or brazing at lower temperatures is required, AA-4045 is the preferred choice.

Double clad brazing aluminum strip Technical Information

| Product Name | Description | Core Layer Alloy | Blazing Layer Alloy | Water-contact Side Alloy | Temper | Application | Thickness (mm) |

| HC807 | 3003/4343/7072 | 3003 | 4343 | 7072 | H14 | Tube | 0.2-0.4 |

| HC808 | 3003+Cu/4343/7072 | 3003+Cu | 4343 | 7072 | H14 | Tube | 0.2-0.4 |

| HC816 | 3Z22/4343/7072 | 3Z22 | 4343 | 7072 | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC817 | 3Z22/4045/7072 | 3Z22 | 4045 | 7072 | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC818 | 3Z23/4343/ | 3Z23 | 4343 | / | O, H14, H24, H16, H26 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC801 | 3003/4343 (Single cladding) | 3003 | 4343 (Single cladding) | / | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC802 | 3003/4343 (Double cladding) | 3003 | 4343 (Double cladding) | / | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC807 | 3003/4343/7072 | 3003 | 4343 | 7072 | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC808 | 3003+Cu/4343/7072 | 3003+Cu | 4343 | 7072 | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

| HC810 | 3003+Cu/4045/7072 | 3003+Cu | 4045 | 7072 | O, H14 | Tube, Main Board/Side Board | 0.2-5.0 |

Brazing Aluminium Clad Metal For Heat Exchangers Production Specification

| Specification | Clad material | Non-clad material |

| Single-face clad/clad rate | 4-30 | — |

| Double-face dad/clad rate | 4-15 | — |

| Thickness range | 0.05-6.0 | 0.05-6.0 |

| Plates width range | 450-2200 | 450-2200 |

| Plates length range | 500-15000 | 500-15000 |

| Coiled material width range | 12-2200 | 12-2200 |

| Coiled material outer diameter | Max 2500 | Max 2500 |

Features of Double Clad Brazing Aluminum Strip

- Double Coating: The double-clad aluminum strip typically has a layer of brazing flux or active metal coating, such as magnesium or silicon alloys, applied to its surface. This coating helps facilitate the brazing process at high temperatures, reducing the required brazing temperature and time, thereby improving welding quality.

- Excellent Brazing Properties: The design of the aluminum brazing alloy strip is optimized for the brazing process, ensuring efficient heat exchange performance in air conditioning systems while reducing welding defects such as porosity and cracking.

- Good Corrosion Resistance: Since air conditioning systems typically operate in humid environments, the aluminum brazing alloy strip must have excellent corrosion resistance, particularly in low-temperature environments, to withstand the effects of moisture and salts in the air.

- High Thermal Conductivity: Aluminum has high thermal conductivity, so when the aluminum strip is used in heat exchanger components, it can effectively transfer heat, improving the thermal efficiency of the air conditioning system.

- Workability: The aluminum strip has good machinability and can be precisely cut, bent, and formed as required, making it easy to customize for different air conditioning system designs.

Applications of Double Clad Brazing Aluminum Strip

- Heat Exchanger Manufacturing: The evaporators, condensers, and heat exchangers in air conditioning systems are typically made from aluminum brazing alloy double-clad strips. Due to their excellent thermal conductivity, they effectively transfer heat, enhancing the energy efficiency of the air conditioning system.

- Condensers and Evaporators: The condenser in an air conditioning system needs to efficiently dissipate heat, while the evaporator absorbs heat. The use of aluminum brazing alloy strips improves the brazing performance and structural strength of these components.

- High-Temperature and High-Pressure Environments: This aluminum strip can withstand high pressures and temperature variations in air conditioning equipment, making its heat resistance and anti-deformation capabilities crucial for ensuring the stability of the equipment.

Advantages of Double Clad Brazing Aluminum Strip

- Improved Efficiency: The efficient brazing process increases the overall thermal efficiency of air conditioning equipment, reducing energy losses.

- Enhanced Durability: The double coating and excellent corrosion resistance allow the aluminum strip to withstand higher pressure and corrosion over extended use, extending the lifespan of the equipment.

- Cost Reduction: Optimized brazing properties lower production costs and improve manufacturing efficiency.

The double-clad brazing aluminum strip for air conditioning systems offers excellent brazing performance, corrosion resistance, and thermal conductivity, making it a valuable material in air conditioning and refrigeration systems.

Maybe also you like: