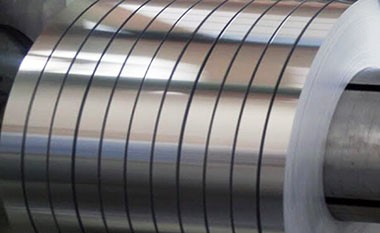

HVAC Condenser Hot Cold Rolled Brazing Aluminum Cladded Sheet/Strip/Coil for Car Radiator

Automotive radiator and HVAC (Heating, Ventilation, and Air Conditioning) condenser brazed aluminum composite sheet/strip/coils are high-performance materials specially designed for automotive heat dissipation and HVAC systems.

HVAC Condenser Brazed Aluminum Composite Material Composition

Aluminum Alloy: This composite sheet/strip/coils is primarily made of aluminum alloy, which has excellent thermal conductivity and corrosion resistance, making it suitable for use in radiators and condensers.

Composite Structure: It is typically made of multiple layers of aluminum materials bonded together through a specific brazing process. This structure enhances the material's strength and durability while maintaining good heat conduction properties.

HVAC Condenser Brazing Process Features

Hot Cold Rolling Process: The material is produced using a hot-cold rolling process, ensuring uniformity and compactness of the aluminum, thereby improving the material's mechanical properties.

Brazing Technology: The aluminum layers are bonded together using high-temperature brazing technology, forming a strong composite structure that can withstand high pressure and temperature environments.

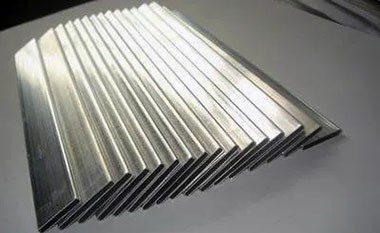

Hot Cold Rolled Brazing Aluminum Specifications

- Thickness and Width: Sheets, strips, and coils with different thicknesses and widths are available according to customer requirements.

- Surface Treatment: Surface treatments such as anodizing and coating can be applied as needed to enhance corrosion resistance and appearance.

- Temper: HO/H14/H16/H18/H24

- Size: Fin: 0.07/0.08 * (16-28)mm

- Tube: (0.27-0.32)*(35-75)mm

- Plate: (0.6-1.5)*(1070/1000/659)*(500-2500)mm

- Cladding Rate: 4~18% (each side)

Hot Cold Rolled Brazing Aluminum Core material

| Alloy No. | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | 0.1 | - | - |

| 3003+1%Zn | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | 0.5-1.5 | - | - |

| 3003+1.5%Zn | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | 1.0-2.0 | - | - |

| 3003+1.5%Zn+Zr | 0.65~1.0 | 0.4 | 0.05 | 1.4-1.8 | 0.03 | 1.3-1.7 | 0.05-0.2 | - |

| 3003+0.5%Cu | 0.6 | 0.7 | 0.3-0.7 | 1.0-1.5 | - | 0.1 | - | - |

| 3005 | 0.6 | 0.7 | 0.2-0.4 | 1.0-1.5 | - | 0.25 | - | - |

Hot Cold Rolled Brazing Aluminum Clad Alloy

| Alloy Grade | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti |

| 4343 | 6.8-8.2 | 0.8 | 0.25 | 0.1 | - | 0.2 | - | - |

| 4343+1%Zn | 6.8-8.2 | 0.8 | 0.25 | 0.1 | - | 0.5-1.5 | - | - |

| 4045 | 9.0-11.0 | 0.8 | 0.3 | 0.05 | 0.05 | 0.1 | - | 0.2 |

| 4045+1%Zn | 9.0-11.0 | 0.8 | 0.3 | 0.05 | 0.05 | 0.5-1.5 | - | 0.2 |

| 4004 | 9.0-11.0 | 0.8 | 0.25 | 0.1 | 1.0-2.0 | 0.2 | - | - |

| 7072 | 0.1 | 0.1 | 0.1 | 0.8-1.3 | - | - | ||

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.5-1.0 | - | - |

HVAC Condenser Brazed Aluminum Composite Performance Advantages

- Excellent Thermal Conductivity: Aluminum has a high thermal conductivity, allowing it to quickly dissipate heat and improve heat dissipation efficiency.

- Lightweight: Aluminum alloys are lighter than traditional materials, helping to reduce vehicle weight and improve fuel efficiency.

- Corrosion Resistance: After corrosion protection treatment, aluminum materials exhibit good resistance to corrosion, extending the lifespan of radiators and condensers.

- Good Workability: This composite material is easy to cut, form, and weld, making it convenient for manufacturing and installation.

Applications

Automotive Radiators: Used in automotive engine cooling systems to help control engine temperature.

HVAC Systems: Used as the core material in condensers for air conditioning systems in buildings and vehicles, enhancing cooling efficiency.

Automotive Radiator and HVAC Condenser Brazed Aluminum Composite Sheet/Strip/Coils is a high-performance material that combines excellent thermal conductivity, lightweight properties, and corrosion resistance. It is widely used in automotive and HVAC systems and is an essential component in improving heat dissipation efficiency and overall system performance.

Maybe also you like: