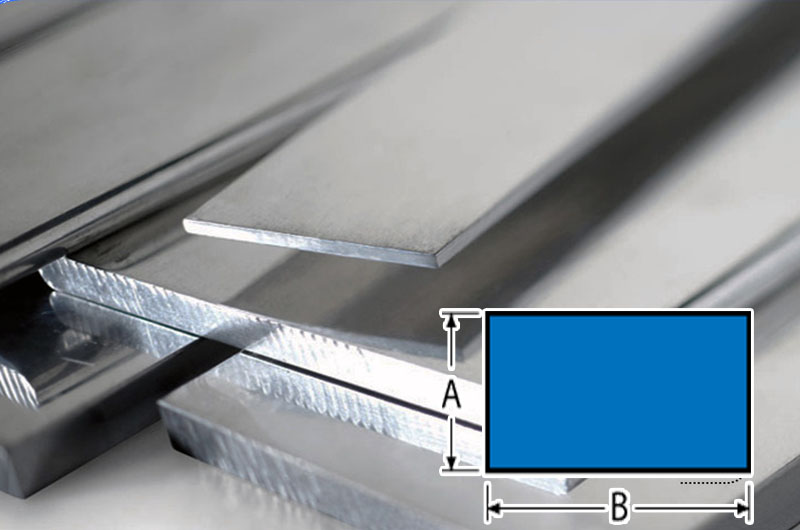

Types of Aluminum Profiles

Industrial aluminum alloy profiles are known as a non-ferrous metal structural material commonly used in various industries, including aerospace, machinery manufacturing, automotive, shipping, and architectural decoration.

Aluminum profiles are widely used in modern industry and construction, and can be categorized into various types based on different classification standards.

Classification of Aluminum Profiles by Use

Building Aluminum Profiles

- Used for the external facade of buildings, windows, door frames, curtain walls, etc., featuring good corrosion resistance and aesthetics.

- Characteristics: Good corrosion resistance and strength, with surface treatments (such as anodizing, spraying) to enhance durability and aesthetics.

- Common alloys include 6063 and 6061, suitable for surface treatments like anodizing and spraying.

Radiator Aluminum Profiles

- Mainly used for manufacturing radiators, featuring good thermal conductivity and heat dissipation performance.

- Characteristics: Excellent thermal conductivity and heat dissipation, typically designed in porous or fin structures to enhance cooling effect.

- Common alloy is 1060, suitable for high-temperature and high-pressure environments.

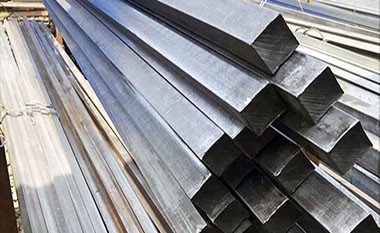

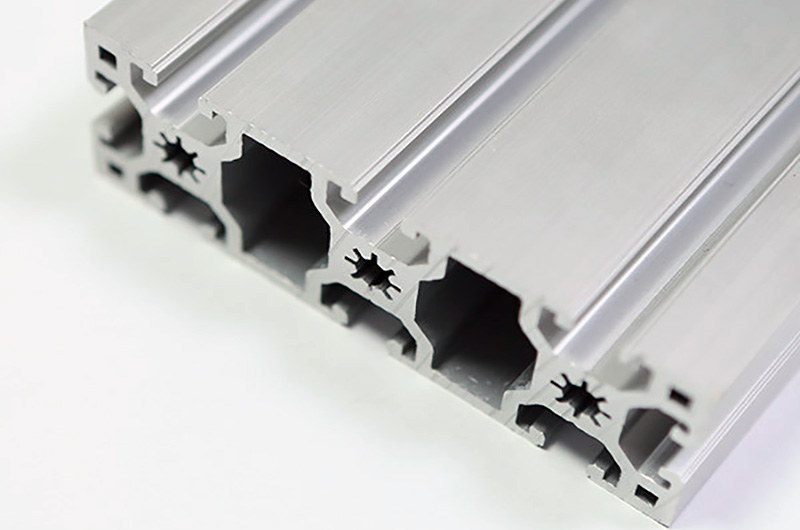

Industrial Aluminum Profiles

- Used for machinery equipment, production line supports, frames, etc., with high strength and rigidity.

- Characteristics: High strength, good wear resistance, and customizable shapes and sizes based on different needs.

- Common alloys include 6061 and 6082, suitable for welding and machining.

Rail Vehicle Structural Aluminum Alloys

- Mainly used for manufacturing the bodies and chassis of rail transit vehicles, requiring lightweight and high strength.

- Characteristics: Lightweight, high strength, able to bear significant loads, with excellent corrosion resistance.

- Common alloys include 6005 and 6061, with good fatigue resistance.

Framing Aluminum Profiles

- Commonly used in framing for pictures and artwork, requiring an elegant appearance and lightweight.

- Characteristics: Aesthetically pleasing, lightweight, and easy to process, can be customized according to design needs.

- Common alloy is 6063, with diverse surface treatments.

Classification by Alloy Composition

1xxx Series (e.g., 1050, 1060):

Pure aluminum, featuring good corrosion resistance and electrical conductivity, suitable for the electrical and chemical industries.

2xxx Series (e.g., 2011, 2024):

Copper alloys with high strength but lower corrosion resistance, commonly used in aerospace and military applications.

6xxx Series (e.g., 6061, 6063, 6082):

Silicon-magnesium alloys with moderate strength, easy to process and surface treat, widely used in construction, machinery, and transportation.

7xxx Series (e.g., 7075):

Zinc alloys with high strength, primarily used in aerospace and high-strength structural components, but with poor weldability.

Aluminum profiles come in various types, suitable for different industries and applications. Choosing the right aluminum profile can enhance product performance and lifespan while effectively reducing costs.

| Aluminum Alloy Grade | Application Field | Characteristics |

| 2011 | Precision mechanical parts, machining tools | Excellent cutting performance, suitable for machining complex shapes, moderate strength |

| 6063 | Building profiles, decorative profiles | Good extrusion performance and surface treatment capability, suitable for construction and decoration industries |

| 6061 | Aerospace, automotive, mechanical engineering fields | Good welding performance and corrosion resistance, high strength and formability |

| 6082 | Structural applications (bridges, building supports) | High strength and corrosion resistance, suitable for heavy-load structural components |

| 7075 | Aerospace, high-strength structural components | Extremely high strength and hardness, suitable for aircraft structural parts, with poor corrosion resistance |

Maybe also you like: