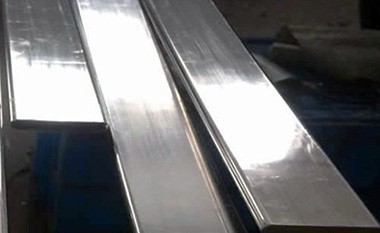

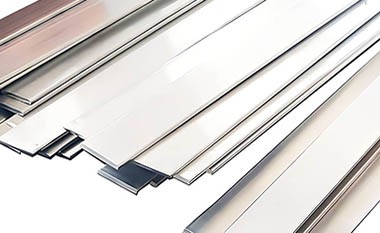

1050 aluminum flat bar busbar

1050 aluminum busbars are made from 1050 aluminum alloy, with an aluminum content of at least 99.5%. This high purity gives the alloy excellent electrical and thermal conductivity, making it an ideal choice for electrical applications.

1050 aluminum busbars (aluminum flat bars) are a type of high-purity aluminum alloy, classified as EC-grade aluminum (electrical conductivity grade aluminum). These aluminum busbars are widely used in electrical distribution systems, primarily as electrical conductors.

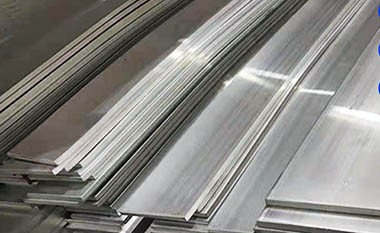

1050 aluminum busbars are essential components in electrical systems, offering high conductivity, corrosion resistance, and excellent workability, making them suitable for a wide range of industrial applications.

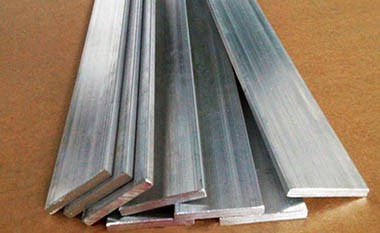

Characteristics of 1050 Aluminum Flat Bar Busbars

- Electrical conductivity: 1050 aluminum has high electrical conductivity, approximately 57% of the International Annealed Copper Standard (IACS), ensuring efficient power transmission.

- Corrosion resistance: The purity of the 1050 alloy provides excellent corrosion resistance, enhancing the durability and lifespan of the busbars in various environments.

- Lightweight: Aluminum has a low density, making 1050 aluminum busbars much lighter than copper busbars of the same size, which facilitates transportation and installation.

- Heat dissipation: Aluminum busbars can effectively dissipate heat, reducing the risk of overheating and improving system safety and reliability.

- Cost-effectiveness: Compared to copper and other metals, 1050 aluminum busbars are more cost-effective, making them an economical choice for electrical applications.

- Thermal conductivity: Aluminum has good thermal conductivity, enabling quick heat dissipation, reducing the thermal load on electrical equipment, and extending its service life.

- Workability: 1050 aluminum has excellent ductility, allowing it to be easily formed into various shapes and sizes, including flat bars, rods, and tubes.

Specification of HC Aluminum 1350 electrical busbar

| Material | Grade | Thickness Range (mm) | Width Range (mm) | Length Range (mm) |

| Aluminum | 1050 | 1 - 20 | 15 - 200 | 1000 - 5000 |

1050 aluminum busbars are typically produced in flat bar form and can be customized in various sizes and thicknesses according to customer requirements. Processing methods include cutting, bending, and welding to accommodate different installation environments.

1050 aluminum busbar Chemica Composition

| Element | Symbol | Composition (wt. %) |

| Aluminum | Al | Minimum 99.50% |

| Copper | Cu | Maximum 0.05% |

| Iron | Fe | Maximum 0.40% |

| Silicon | Si | Maximum 0.25% |

| Manganese | Mn | Maximum 0.05% |

| Magnesium | Mg | Maximum 0.05% |

| Zinc | Zn | Maximum 0.10% |

| Titanium | Ti | Maximum 0.05% |

| Other elements | - | Each 0.05% max, total 0.15% max |

Physical Properties of 1050 Aluminum Busbars

| Property | Description |

| Density | Approximately 2.7 g/cm³; its lightweight nature facilitates easier installation and transportation. |

| Strength | Although not as strong as copper, it is sufficient within its application range and can withstand normal mechanical stress. |

| Corrosion Resistance | Forms an oxide layer on the surface, providing good corrosion resistance, making it suitable for various environments. |

Applications of 1050 Aluminum Busbars

1. Power Distribution Systems

Application Scenario: 1050 aluminum busbars are widely used in substations, distribution cabinets, and electrical distribution networks.

Function: As a key component for power delivery, aluminum busbars effectively transmit current and reduce power loss. Their lightweight nature makes installation easier and reduces structural load.

Advantage: The corrosion resistance and oxidation resistance of aluminum ensure good performance and a long lifespan when used outdoors or in harsh environments.

2. Industrial Electrical Equipment

Application Scenario: In large industrial equipment and machinery, 1050 aluminum busbars serve as the main power supply introduction and distribution.

Function: They efficiently transfer electricity from the power source to various equipment, ensuring normal operation. The conductivity of aluminum makes energy transmission more efficient.

Advantage: The lightweight characteristic of aluminum busbars facilitates installation and maintenance in large equipment while reducing the requirements for supporting structures.

3. Building Electrical Systems

Application Scenario: In high-rise buildings and large facilities, 1050 aluminum busbars are part of the main power supply lines.

Function: They ensure efficient power transmission to meet the electricity needs of various electrical devices within the building. They are often used in power distribution systems to ensure reliability and stability.

Advantage: The corrosion resistance and good thermal conductivity of aluminum busbars effectively prevent overheating and corrosion in building electrical systems, enhancing safety and durability.

HC Aluminum offers a comprehensive range of electrical busbar products, including aluminum busbars, copper busbars, and copper-clad aluminum busbars. Popular aluminum busbar products such as 6101, 1050, 1060, 1070, 1100, 1350, 6061, 6063, and 6082 are widely used as electrical conductors in distribution systems.