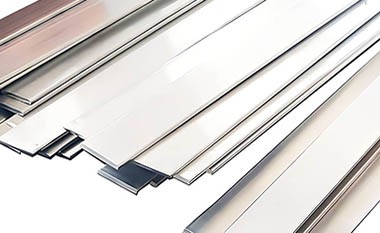

1070 Electrical Aluminum Busbar

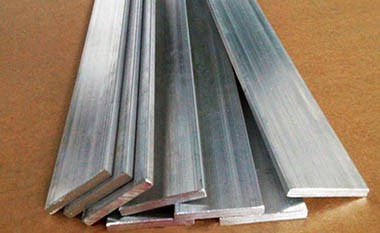

1070 Aluminum Busbar is a high-purity aluminum conductor, typically containing more than 99.7% aluminum. This composition gives it excellent conductivity and corrosion resistance, making it an ideal choice for power distribution systems.

1070 Aluminum Busbar provides an economical, durable, and efficient solution for power distribution needs, combining high conductivity with outstanding resistance to environmental factors.

The mechanical strength of 1070 aluminum is relatively low (soft and highly ductile), which limits its use in high-stress environments unless reinforced.

1070 electrical aluminum busbar is a widely used aluminum alloy conductor in power systems and distribution equipment, primarily used for transmission and distribution.

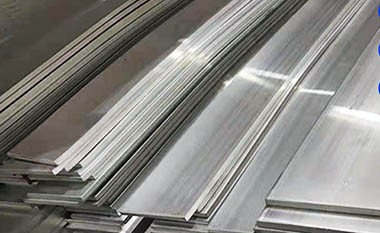

1070 Aluminum Busbar Specifications

| Specification | Details |

| Material | 1070 Aluminum |

| Length | Up to 6 meters |

| Width | 10mm to 200mm |

| Thickness | 0.15mm to 40mm |

| Tolerance | +/- 0.1mm |

| Surface Treatment | Zinc, Nickel, Tin, Silver, etc. |

| Standards | ASTM B236 (Electrical conductor-grade aluminum) |

| IEC 60439 (Low-voltage switchgear and controlgear) |

1070 Aluminum Busbar Physical Properties

- Electrical Conductivity: ~62% IACS (International Annealed Copper Standard), making it suitable for electrical applications despite lower conductivity than copper.

- Thermal Conductivity: High, aiding in heat dissipation.

- Density: 2.7 g/cm³, offering significant weight savings over copper (≈60% lighter for equivalent volume).

The specifications of the 1070 aluminum busbar typically include width, thickness, and length, which can be customized according to user requirements, complying with national and international electrical standards such as GB, IEC, etc.

HC Aluminum 1070 EC grade aluminum busbars comply with IEC 60105, ISO 209-1, 2, DIN EN 755-2, and DIN EN 755-5 standards, possessing good ductility, high formability, and tensile toughness, fully meeting standard processing requirements (stamping, stretching).

Features of 1070 Aluminum Busbar

| Features | Description |

| High Conductivity | The aluminum content of 1070 aluminum alloy exceeds 99.7%, resulting in very high conductivity, suitable for applications requiring excellent electrical performance. |

| Corrosion Resistance | Aluminum easily forms an oxide layer in air, effectively resisting corrosion, making it suitable for use in various environments. |

| Good Processing Performance | 1070 aluminum alloy is easy to extrude and shape, allowing for the manufacture of various specifications and dimensions based on different requirements. |

| Oxidation Resistance | In high-temperature or humid environments, the 1070 aluminum busbar maintains good electrical performance. |

| Non-Magnetic | The 1070 aluminum busbar is non-magnetic, preventing magnetic hysteresis losses when in contact with other metals, making it suitable for applications with strict magnetic requirements. |

Chemical Composition of HC Aluminum 1070 conductive aluminum busbar

| Element | Symbol | Typical Content (%) |

| Aluminum | Al | 99.7 (min) |

| Copper | Cu | 0.05 (max) |

| Iron | Fe | 0.4 (max) |

| Silicon | Si | 0.25 (max) |

| Manganese | Mn | 0.03 (max) |

| Magnesium | Mg | 0.03 (max) |

| Zinc | Zn | 0.1 (max) |

| Titanium | Ti | 0.1 (max) |

| Other Elements | - | 0.15 (max) each |

Advantages of 1070 Aluminum Busbar Compared to Copper

| Advantage | Description |

| Cost-effective: Lower material and installation costs | 1070 Aluminum Busbar offers significant cost advantages compared to copper. The price of aluminum is generally lower than copper, so using aluminum busbars can effectively reduce initial procurement costs. Additionally, the installation costs of 1070 aluminum busbars are lower, as aluminum has a lower density than copper, making transportation and handling more convenient. With both material and installation cost savings, 1070 aluminum busbars provide a more cost-effective solution for power systems. |

| Lightweight: Reduces structural support requirements | Due to its lower density, 1070 Aluminum Busbar is much lighter than copper. This lightweight feature reduces the need for supporting structures during installation, thereby lowering the cost and difficulty of the supporting infrastructure. Especially in large power systems, using aluminum busbars can significantly reduce the overall weight burden, simplify structural design, and make transportation and installation more efficient. |

| Abundant: Readily available and sustainable choice | 1070 Aluminum Busbar is a very abundant resource, with a relatively stable and widely available supply of aluminum, making this material easy to source in the market. Aluminum is also a sustainable material, as its recycling process is simple and efficient, meeting green environmental requirements. The high recycling rate of aluminum allows it to be remelted and processed after use, further reducing the demand for new resources. |

1070 Aluminum Busbar Compared to 1350 Aluminum

The conductivity of 1070 Aluminum Busbar is slightly lower than that of 1350 aluminum, but it remains a highly suitable choice, especially for fixed installations. While the conductivity of 1350 aluminum is approximately 63% IACS, which is commonly used for overhead lines and applications requiring higher conductivity, 1070 aluminum busbars offer an excellent cost-performance ratio, making them an economical choice for fixed installations.

Although 1070 aluminum busbars have slightly lower conductivity than 1350 aluminum, their lower cost makes them very popular in many fixed installation scenarios. Especially in environments where the conductivity requirements are not extremely stringent, 1070 aluminum can provide sufficient current-carrying capacity while significantly reducing material procurement and installation costs. Due to its good mechanical strength and durability, 1070 aluminum busbars remain stable during long-term use, making them an economical and reliable solution.

Therefore, 1070 aluminum busbars not only offer cost efficiency in applications but also meet most fixed installation needs, especially when extremely high conductivity is not required, making them an ideal alternative to 1350 aluminum.

Advantages and Limitations of 1070 Aluminum Busbar

The 1070 aluminum busbar has significant advantages in terms of lightweight construction, conductivity, and cost-effectiveness, but it also has certain limitations regarding strength and connection technologies.

Advantages of 1070 Aluminum Busbar

Lightweight, easy to install and transport

The density of 1070 aluminum busbar is about one-third that of copper, giving it a clear weight advantage. This lightweight feature not only reduces transportation costs but also simplifies and enhances the installation process, especially in space-constrained situations.

Excellent conductivity and corrosion resistance

The high conductivity of 1070 aluminum alloy effectively transmits electrical current. Additionally, aluminum naturally forms a protective aluminum oxide layer in the air, providing good corrosion resistance. This makes the aluminum busbar more reliable in humid or corrosive environments.

Relatively low cost and good economic efficiency

The raw material cost of aluminum is typically lower than that of copper, and the processing and forming technologies for aluminum are relatively mature. Therefore, the 1070 aluminum busbar can significantly reduce overall costs in large-scale applications, making it an economically practical choice.

Limitations

Compared to copper, aluminum has lower strength, which may require larger cross-sections to handle the same electrical load.

The connection technology for aluminum is more demanding and may lead to contact resistance issues.

Application Fields of 1070 Aluminum Busbar

| Application Field | Description |

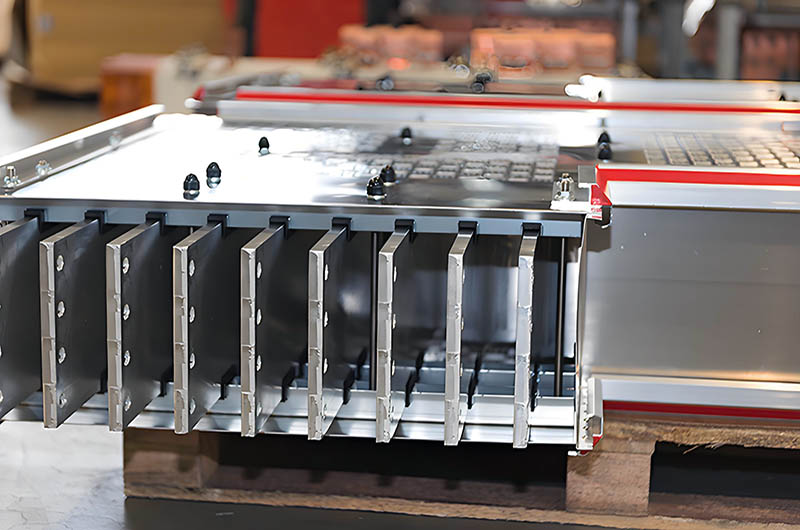

| Power Distribution Systems | The 1070 aluminum busbar is widely used in substations, distribution rooms, and electrical distribution in buildings, serving as the primary carrier for power transmission, efficiently distributing electrical energy to meet different load demands. |

| Electrical Equipment Connections | This aluminum busbar is used to connect various electrical devices, such as transformers and generators, ensuring efficient current transmission, reducing energy loss, and improving system reliability. |

| Industrial Automation | In industrial automation equipment, the 1070 aluminum busbar is used to supply power to electrical and control systems, supporting the efficient operation of automated production lines, improving productivity and safety. |

Manufacturing and Installation

- Production: Extruded or rolled into rectangular bars, rods, or custom profiles.

- Surface treatment: Anodizing, tin plating, or grease coating to reduce oxidation.

- Connection methods: Welding (TIG/MIG) or bolted connections with corrosion-resistant hardware (e.g., stainless steel bolts, isolation pads).

1070 electrical aluminum busbars are an economical, lightweight solution suitable for medium to high current applications where weight and budget are critical. With proper design and installation, its limitations can be mitigated, making it an indispensable part of modern electrical infrastructure.