2024 aluminum flat bar

2024 aluminum flat bar is a high-strength aluminum alloy primarily composed of aluminum, copper, and small amounts of other elements (such as manganese, magnesium, and silicon). It is widely used in aerospace, automotive, military, and other high-demand industrial fields due to its excellent mechanical properties and good fatigue resistance.

The 2024 aluminum flat bar is a versatile alloy suitable for various applications, ranging from consumer goods to aerospace components. 2024 aluminum is highly workable and can be polished to A2 grade.

2024 Aluminum Flat Bar Specifications

- ASTM B211

- AMS 4120S

- AMS QQ A 225/6

2024 Aluminum Flat Bar Characteristics

- 1. High Strength: 2024 aluminum alloy has good tensile and yield strength, making it suitable for high-load applications.

- 2. Good Workability: Despite the high strength of 2024 aluminum alloy, it still possesses good machinability and can be processed through cutting, welding, and forming techniques.

- 3. Corrosion Resistance: Although the corrosion resistance of 2024 aluminum alloy is relatively low, it can be significantly enhanced through proper surface treatments (such as anodizing).

- 4. Lightweight: The inherent lightweight characteristics of aluminum alloys make the 2024 aluminum flat bar very popular in applications where weight reduction is crucial.

- 5. Good Fatigue Strength: 2024 aluminum alloy demonstrates good fatigue strength under repeated stress, making it suitable for high-stress environments such as aerospace.

HC Aluminum Popular 2024 Aluminum Flat Bar

-

2024 T351 Aluminum Flat Bar

The 2024 T351 aluminum flat bar is a high-strength aluminum alloy commonly used in aerospace and military applications. It offers excellent fatigue resistance and machinability, making it suitable for applications that require a combination of lightweight and strength, such as aircraft structures and components.

-

Aluminum Flat Bar 2024 T351 Cold Finished

Cold finishing improves the 2024 flat bar's mechanical properties and surface quality, making it ideal for precision applications in the aerospace industry where tight tolerances and surface integrity are critical.

-

2024 Aerospace Aluminum Flat Bar

The 2024 aerospace aluminum flat bar is specifically designed for use in aerospace applications. This alloy is known for its high strength-to-weight ratio and is often utilized in aircraft components, including wings and fuselage structures. It exhibits good machinability and excellent resistance to fatigue.

2024 Aluminum Flat Bar Heat Treatment

2024 aluminum alloy can enhance its strength through heat treatment processes such as aging and solution heat treatment. Common tempers include T3, T4, and T6.

- T3: Solution heat treated followed by natural aging, providing good strength and toughness.

- T6: Solution heat treated followed by artificial aging, providing the highest strength.

2024 Aluminum Flat Bar Corrosion Resistance

The corrosion resistance of 2024 aluminum alloy is relatively low, and it typically requires surface treatment (such as anodizing) to improve its corrosion resistance, especially in humid or corrosive environments.

2024 Aluminum Flat Bar Machining Methods

- Cutting and Shaping: 2024 aluminum flat bars can be processed into the desired sizes and shapes through cutting, stamping, forging, and other methods.

- Machining: Operations such as drilling, milling, and turning can be performed, making it suitable for manufacturing precision components.

- Surface Treatment: Anodizing, spraying, or coating can be applied to enhance appearance and corrosion resistance.

Chemical composition of 2024 aluminum flat bar

| Element | Composition (%) |

| Si | 0~0.5% |

| Fe | 0~0.5% |

| Cu | 3.8~4.9% |

| Mn | 1.2~1.8% |

| Mg | 0.3~0.9% |

| Cr | 0~0.1% |

| Zn | 0~0.25% |

| Ti | 0~0.15% |

| Al | 92~93.5% |

Mechanical properties of 2024 aluminum flat bar

| Temper | T3 | T351 | T851 | T4 | O |

| Density | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 |

| Ultimate Tensile Strength (ksi) | 70 (bare); 65 (clad) | 67 | 75 | 69 | 27 (bare); 26 (clad) |

| Yield Tensile Strength (ksi) | 50 (bare); 45 (clad) | 47 | 66 | 45 | 11 |

| Elongation at Break (%) | 18 | 13 | 4.90 | 16 | 20 |

| Fatigue Strength (ksi) | 20 | 20 | 17 | 20 | 13 |

| Hardness Rockwell | Brinell | B75 | 120 | B75 | 120 | B84 | 140 | B75 | 120 | N/A | 47 |

| Modulus of Elasticity (ksi) | 10, 600 | 10, 000 | 10, 000 | 10, 000 | 10, 600 |

| Machinability (%) | 70 | 70 | 70 | 70 | 30 |

| Thermal Conductivity (BTU-in/hr-ft^2-°F) | 840 | 840 | 1, 050 | 840 | 1, 340 |

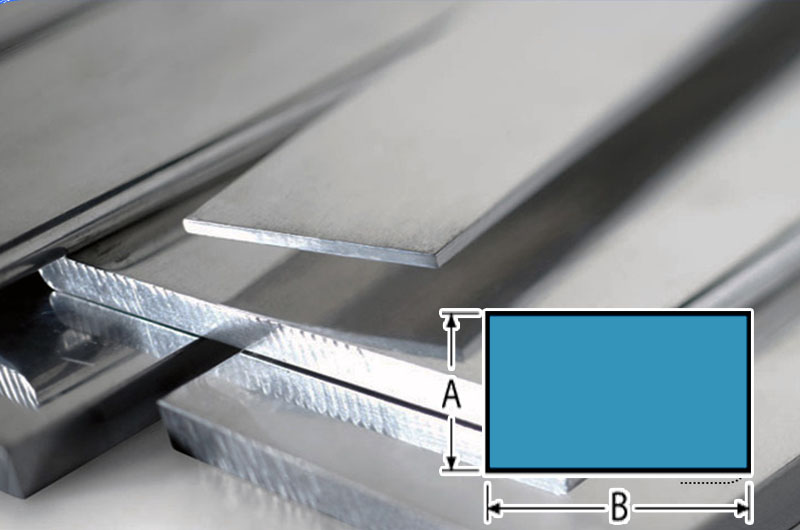

Aluminium Alloy 2024 Flat Bar Stock List

| Description | A(inch) | B(inch) |

| 1/2"(A) X 5/8"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 1/2" | 5/8" |

| 1/2"(A) X 1"(B) 2024 T351 Aluminum Flat Bar | 1/2" | 1" |

| 1/2"(A) X 1-1/2"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 1/2" | 1-1/2" |

| 1/2"(A) X 2"(B) 2024 T351 Aluminum Flat Bar | 1/2" | 2" |

| 5/8"(A) X 3/4"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 5/8" | 3/4" |

| 5/8"(A) X 1"(B) 2024 T351 Aluminum Flat Bar | 5/8" | 1" |

| 5/8"(A) X 1-1/2"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 5/8" | 1-1/2" |

| 5/8"(A) X 2"(B) 2024 T351 Aluminum Flat Bar | 5/8" | 2" |

| 3/4"(A) X 1"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 3/4" | 1" |

| 3/4"(A) X 1-1/4"(B) 2024 T351 Aluminum Flat Bar | 3/4" | 1-1/4" |

| 3/4"(A) X 1-1/2"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 3/4" | 1-1/2" |

| 3/4"(A) X 1-3/4"(B) 2024 T351 Aluminum Flat Bar | 3/4" | 1-3/4" |

| 3/4"(A) X 2"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 3/4" | 2" |

| 1"(A) X 1-1/4"(B) 2024 T351 Aluminum Flat Bar | 1" | 1-1/4" |

| 1"(A) X 1-1/2"(B) Aluminum Flat Bar 2024 T351 Cold Finished | 1" | 1-1/2" |

| 1"(A) X 1-3/4"(B) 2024 T351 Aluminum Flat Bar | 1" | 1-3/4" |

| 1"(A) X 2"(B) 2024 T351 Aluminum Flat Bar | 1" | 2" |

Applications of 2024 Aluminum Flat Bar

1. Aerospace

In the aerospace field, 2024 aluminum flat bars are widely used in several key structural components.

Aircraft Structural Components: Due to their high strength and lightweight characteristics, 2024 aluminum flat bars effectively reduce the overall weight of aircraft, thereby improving flight efficiency and fuel economy.

Fuselage Frame: When used in fuselage structures, 2024 aluminum flat bars provide excellent strength and stiffness, ensuring that the fuselage can withstand various pressures and loads during flight.

Wings and Control Surfaces: The application of 2024 aluminum flat bars in wings and control surfaces further enhances the aerodynamic performance of the aircraft, improving flight stability.

2. Automotive Industry

In the automotive industry, 2024 aluminum flat bars are used to manufacture structural components for various high-performance vehicles.

Frames and Brackets: The lightweight design of 2024 aluminum alloy allows for the manufacture of robust vehicle frames, enhancing the overall safety and stability of the vehicle.

Load-Bearing Structures: When used in chassis and load-bearing structures, 2024 aluminum alloy effectively reduces vehicle weight, improving handling and fuel efficiency, which is especially important in high-performance models.

3. Mechanical Engineering

In the field of mechanical engineering, 2024 aluminum flat bars are widely applied in components that require high strength and stiffness due to their outstanding mechanical properties.

Gears and Bearings: In certain machinery, 2024 aluminum alloy flat bars can be used to manufacture gears and bearings, providing good friction characteristics and wear resistance.

Supports: Used to support and secure various mechanical components, they can withstand significant loads, maintaining the stability of the equipment.

4. Consumer Goods

Sports Equipment: High-end sports equipment, such as bicycle frames and fitness machines, often uses 2024 aluminum alloy flat bars, enhancing product performance due to their lightweight and high-strength characteristics.

Furniture: In the manufacture of high-end furniture, 2024 aluminum alloy flat bars can be used as structural materials, increasing the durability and aesthetic appeal of the products.