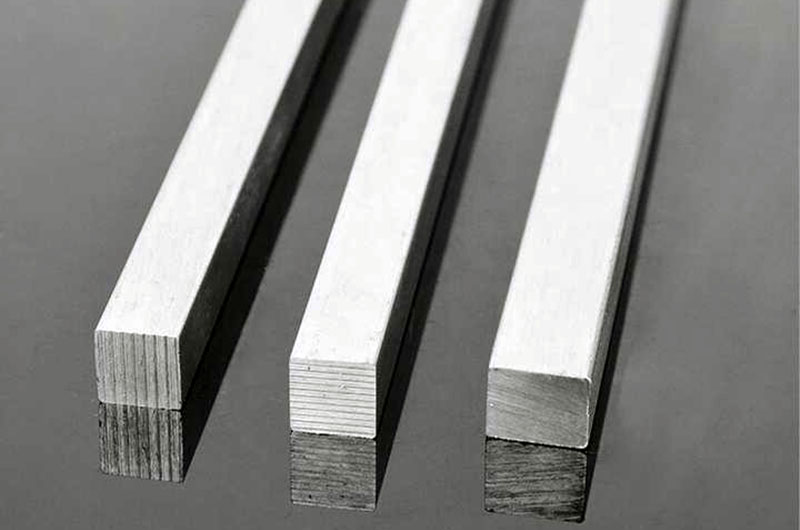

2024 T4 Aluminum Square Bar

2024 T4 aluminum square bars are also high-strength aluminum alloys, offering good formability and mechanical properties. The T4 condition makes it more flexible during processing, making it suitable for manufacturing various components with square cross-sections.

2024 T4 aluminum square bars are high-strength aluminum alloys widely used in aerospace, automotive, and other industrial fields, especially in applications that require strength and lightweight. 2024 aluminum alloy itself has excellent mechanical properties, particularly its tensile strength, which is among the highest of all aluminum alloys. However, 2024 aluminum alloy has relatively poor corrosion resistance, so appropriate surface treatment is often required to improve its corrosion resistance.

2024 T4 Aluminum Square Bar Specifications

| grade | condition | shape | temper | size range | specification |

| 2024 | Cold Finished | Squares | T351 | 1/2" - 4" | AMS 4120 / ASTM B-211 |

| T4 | 1/4" - 3/8" |

2024 T4 Aluminum Condition Characteristics

2024 T4 aluminum square bars undergo solution heat treatment followed by natural aging. This T4 condition aluminum alloy has the following characteristics:

- Excellent strength: In the T4 condition, the aluminum alloy has very high strength, making it suitable for structures and components that bear significant loads.

- Excellent formability: Despite its high strength, 2024 T4 aluminum square bars retain a certain degree of formability. This makes it more flexible during processing, suitable for manufacturing components of various shapes, especially square-section parts.

- Moderate ductility: Although it has high strength, the T4 condition aluminum alloy retains a certain level of ductility, which can meet some complex forming requirements.

- Poor corrosion resistance: Due to the natural aging process, 2024 T4 aluminum alloy has relatively poor corrosion resistance, so additional surface treatments such as anodizing or coatings are often required to improve its corrosion resistance.

2024 T4 Aluminum Square Bar Applications

- Aerospace: Due to its high strength and good formability, 2024 T4 aluminum square bars are widely used in aircraft frames, structural components, and wing parts. In lightweight structural components such as aircraft fuselage, cabin frames, brackets, and stiffeners, 2024 T4 aluminum alloy is an ideal choice.

- Automotive industry: 2024 T4 aluminum square bars are also used in automotive manufacturing, especially in automotive structural components that require strength and lightweight, such as vehicle body frames, chassis structures, and engine mounts.

- Mechanical engineering: This material is also widely used in the mechanical field to manufacture high-strength mechanical components, such as precision parts, shafts, gears, and other load-bearing parts.

- Other industrial applications: 2024 T4 aluminum square bars are also suitable for manufacturing structural components that need to bear significant loads, such as brackets and frames in industrial equipment and structural components in transportation vehicles.

2024 T4 Aluminum Square Bar Advantages and Limitations

Advantages of 2024 T4 Aluminum Square Bar

- High strength: As one of the strongest aluminum alloys, 2024 T4 aluminum square bars are highly effective in applications requiring high strength.

- Excellent formability: The T4 condition allows this aluminum alloy to adapt to complex processing requirements, making it suitable for manufacturing various structural and shaped components.

- Suitable for lightweight structures: Its high strength and relatively low density make 2024 T4 aluminum square bars highly advantageous in industries such as aerospace, which have high lightweight requirements.

Limitations of 2024 T4 Aluminum Square Bar

- Poor corrosion resistance: Compared to other aluminum alloys, 2024 T4 has poor corrosion resistance, so additional surface protection measures are needed.

- Sensitive to environmental factors: In certain harsh environmental conditions (e.g., high humidity, high salinity environments), 2024 T4 aluminum alloy may experience corrosion issues, requiring additional protective measures.

2024 T4 Aluminum Square Bar Processing and Surface Treatment

- Processing: 2024 T4 aluminum alloy square bars have good machinability and can be processed using conventional milling, cutting, and drilling techniques. During hot processing, it is usually performed at medium temperatures to achieve optimal mechanical properties.

- Surface treatment: To improve corrosion resistance, 2024 T4 aluminum alloy is often anodized, electroplated, or coated, especially for applications that will be exposed to harsh environments for extended periods.

2024 T4 aluminum square bars, with their exceptional strength and good formability, are widely used in structural components that require high strength and lightweight, especially in aerospace, automotive, and mechanical fields, and have a broad market demand. Although its corrosion resistance is relatively poor, this limitation can be effectively addressed with proper surface treatments, ensuring excellent performance in a variety of industrial applications.

Popular Lengths or Custom Cuts

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 192" (16 ft.)

- Custom cuts supported

2024 T4 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 45 |

| Brinell Hardness 500 kg load | 120 |

| Ultimate Tensile Strength KSI | 69 |

| Rockwell Hardness B Scale | 75 |

| Elongation % in 2 in. | 16 |

| Melting Point °F | 935 - 1180 |

| Shear Strength KSI | 41 |

| Machinability % | 70 |

| Electrical Conductivity % IACS | 30 |

Chemistry Information 2024 Aluminum

| Element | Percentage |

| Al | 93.5 |

| Cr | 0.1 max |

| Cu | 3.8 - 4.9 |

| Mg | 1.2 - 1.8 |

| Fe | 0.5 max |

| Mn | 0.3 - 0.9 |

| Si | 0.5 max |

| Zn | 0.25 max |

| Ti | 0.15 max |

2024 T4 Aluminum Square Bar Stock List

| Description | alloy | temper | shape | processing-method |

| 0.25" Aluminum Square Bar 2024-T4-Cold Finish | 2024 | T4 | square bar | Cold Finished |