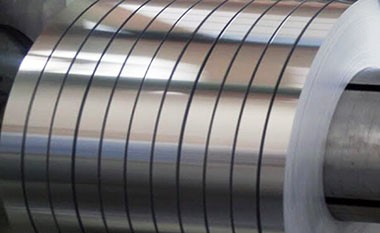

4004/3003/4004 Aluminium brazing sheet strip

4004/3003/4004 aluminum brazing sheet is a multilayer composite material widely used in the manufacturing of brazed heat exchangers. This material's composite structure consists of three layers of aluminum alloy, with 4004 alloy serving as the brazing layer and 3003 alloy as the substrate.

The three-layer aluminum alloy brazing sheet is an important material for manufacturing brazed heat exchangers, with 4004/3003/4004 being the most commonly used aluminum alloy composite brazing sheet.

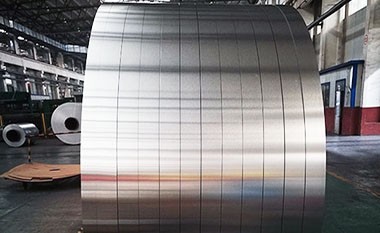

Structure of 4004/3003/4004 Aluminium Brazing Sheet Strip

- Composite Layer: The 4004 alloy serves as the outer layer, providing good brazing performance, while the 3003 alloy serves as the substrate, offering good mechanical strength and corrosion resistance.

- Layered Structure: The structure of this aluminum alloy brazing sheet consists of three layers, with the outer and inner layers being 4004 alloy and the middle layer being 3003 alloy. This structure allows the material to maintain good welding performance while also possessing high strength and stability.

Melting Point Characteristics of 4004/3003/4004 Aluminium Brazing Sheet Strip

Melting Point of 4004 Alloy

- Melting Point: 550-583°C. Its relatively low melting point makes it easy to melt during the brazing process, facilitating the formation of strong welded connections.

- Function: Mainly used as the brazing layer, it provides good fluidity and fillability, ensuring the quality of the weld.

Melting Point of 3003 Alloy

- Melting Point: 643-654°C, which is higher than that of 4004 alloy. This means that during the brazing process, the substrate remains relatively stable, avoiding deformation or damage caused by overheating.

- Function: As the substrate material, 3003 alloy has good corrosion resistance and formability, providing a robust structural foundation for the heat exchanger.

In the 4004/3003/4004 brazing sheet, the melting point of the composite 4004 alloy is more than 60°C lower than that of the 3003 alloy. During the brazing process, the low melting point of the 4004 alloy allows it to melt at lower temperatures, forming strong weld joints without affecting the stability of the 3003 substrate, ensuring the durability and performance of the product.

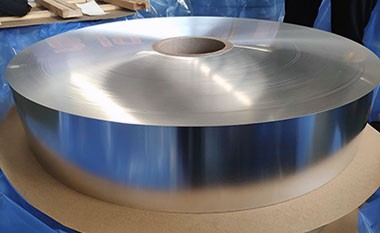

HC Aluminum 4004/3003/4004 Brazing Sheet Strip Specifications

| Alloy | 4004/3003/4004 |

| Temper | O |

| Thickness | 0.5-20mm |

| Width | 500-1500mm |

| Length | Up to 6000mm |

| MOQ | 2500KGS |

| T Standard | GB/3880-2006, GB/3880-2012 |

HC Aluminum 4004/3003/4004 Brazing Sheet Strip Data Parameters

| Property | Parameter |

| Material Grade | 4004/3003/4004 |

| State | H14 |

| Composite Layer (%) | 8–12 |

| Thickness (mm) | 0.60–1.20 |

| Tolerance (mm) | ±0.03 |

| Tensile Strength σb (MPa) | 180–205 |

| Elongation δ (%) | ≥1 |

| Yield Strength σ0.2 (MPa) | ≥160 |

Advantages of 4004/3003/4004 Brazing Aluminum Sheet Strip

1. Good Weldability

Low Melting Point: The melting point of the 4004 alloy ranges from 550 to 583°C, which allows for brazing at lower temperatures compared to other aluminum alloys. This not only improves production efficiency but also reduces energy consumption and lowers operational costs.

Stability During Welding: During the welding process, the 4004 alloy can quickly melt and fill the joint, ensuring good bonding quality, thereby enhancing the overall structural strength of the product.

2. Excellent Mechanical Properties

Strength and Toughness: The addition of the 3003 alloy significantly enhances the overall strength of the brazing aluminum sheet. Its yield strength and tensile strength meet high-demand application scenarios, ensuring the material is less likely to deform or break under pressure and stress.

Corrosion Resistance: The 3003 alloy has good corrosion resistance, allowing the composite material to maintain a longer service life in harsh environmental conditions (such as humidity or chemical corrosion).

3. Thermal Conductivity

Thermal Conductivity: Aluminum alloy materials inherently possess excellent thermal conductivity, enabling the 4004/3003/4004 aluminum brazing sheet to effectively improve the thermal efficiency of heat exchangers. During the heat exchange process, the material can rapidly transfer heat, enhancing the heat exchange effect and improving the overall energy efficiency of the equipment.

4. Lightweight

Lightweight Characteristics: The density of aluminum alloys is significantly lower than that of traditional materials like steel, allowing the 4004/3003/4004 aluminum brazing sheet to meet strength requirements while substantially reducing overall weight. Lightweight design is crucial for the automotive, aerospace, and other transportation industries, helping to reduce energy consumption and improve efficiency.

Easier Installation and Transport: Lighter materials make processing, transporting, and installation more convenient, reducing the risks and costs associated with equipment handling.

Chemical Composition of 4004/3003/4004 Aluminium Brazing Sheet Strip

Core Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti | code |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | 0.1 | 0.05 | 0.03 | 1 |

Cladding Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti | code |

| 4004 | 9.0 - 11.0 | 0.8 | 0.30 | 0.05 | 1.0 - 2.0 | 0.20 | - | 0.20 | 1 |

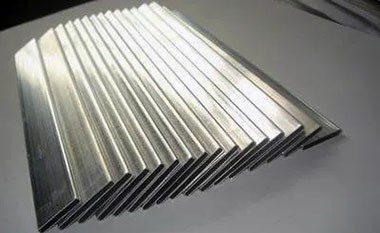

Applications of 4004/3003/4004 Aluminium Brazing Sheet Strip

The 4004/3003/4004 aluminum brazing sheet is widely used in heat exchangers for industries such as air conditioning, cooling systems, automotive, and aerospace. Its excellent thermal conductivity and lightweight characteristics help improve heat exchange efficiency.

- Air conditioning and refrigeration equipment

- Automotive radiators

- Industrial cooling systems

- Solar water heaters, etc.