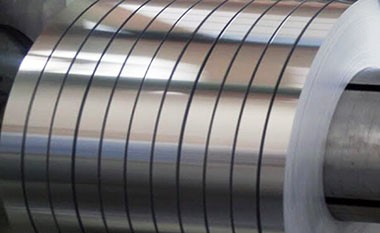

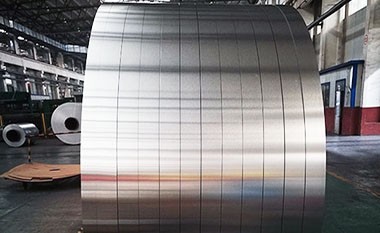

4004 brazing aluminum foil strip coil

4004 brazing aluminum foil strip coil is an aluminum-silicon alloy, primarily used as a cladding layer, playing a critical role in composite materials made from aluminum plates, strips, or foils.

As a type of aluminum-silicon alloy, 4004 aluminum foil strip possesses excellent welding properties and good corrosion resistance, making it suitable for use in high-pressure environments.

The 4004 brazing aluminum foil strip coil is mainly used to manufacture cladding layers for composite materials, especially in applications such as heat exchangers or radiators in the automotive, air conditioning, oxygen generation, and cryogenic equipment fields.

AL 4004 is a general-purpose filler metal specifically designed for joining aluminum and aluminum alloys. During the heat treatment process, the solution temperature must be lower than the solidus line of the brazing alloy to ensure the integrity of the joint is maintained.

4004 aluminum belongs to the 4000 series of aluminum alloys, with silicon being the primary alloying element. The properties described apply to the as-manufactured condition, meaning it has not been tempered or treated.

AL 4004 has a low melting point and a narrow melting range, making it ideal for brazing aluminum alloys. In addition, the silicon content of AL 4004 is higher than that of other aluminum filler metals, which enhances flowability and reduces shrinkage. The use of AL 4004 also significantly reduces the risk of thermal cracking during the brazing process. Furthermore, its increased magnesium content helps prevent oxidation of the brazing surface during heating.

Specifications for AL 4004 Alloy

4004 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-4004. BAlSi-7 is the AWS designation. Additionally, the EN chemical designation is AlSi10Mg1, 5. And the UNS number is A94004.

| Designation Type | Designation |

| Aluminum Association (AA) | 4004 |

| European Standard (EN) | EN AW-4004 |

| AWS (American Welding Society) | BAlSi-7 |

| EN Chemical Designation | AlSi10Mg1, 5 |

| UNS (Unified Numbering System) | A94004 |

Material Properties of 4004 Brazing Aluminum Foil Strip Coil

The main components of 4004 aluminum foil strip are aluminum and silicon. The characteristics of this alloy allow it to melt during vacuum brazing and form a strong bond. The addition of aluminum-silicon alloy improves the flowability and weldability of aluminum, ensuring good performance under high-temperature conditions.

- Composition: The 4004 alloy is primarily composed of aluminum and silicon, with silicon content typically ranging from 4% to 8%. This ratio provides good melting and flow characteristics during brazing.

- Strength and Toughness: Compared to other aluminum alloys, the 4004 alloy maintains relatively high strength and toughness after brazing, making it suitable for withstanding certain pressures and stresses.

Welding Performance of 4004 Brazing Aluminum Foil Strip Coil

During the vacuum brazing process, the cladding layer of the 4004 aluminum foil strip melts, forming a uniform welded joint. The melting temperature and flowability of this material allow it to fill gaps during welding, ensuring the integrity and sealing of the weld. High-quality welding is crucial for guaranteeing the performance of heat exchangers, especially under high-pressure and high-temperature conditions.

Popular Brazing Aluminum Material 4004 from HC Aluminum

HC Aluminum is a global supplier of 4004 aluminum materials, offering various specifications of 4004 composite aluminum.

4004/3003/4004 Aluminium brazing strip

The 4004/3003/4004 Aluminium Brazing Strip is a composite strip that combines the high-silicon content of 4004 alloy with the strength and corrosion resistance of 3003 alloy, making it suitable for various brazing applications, particularly in heat exchangers and refrigeration systems.

AA4004/AA3003/AA4004 h14 Aluminium brazing sheet

The AA4004/AA3003/AA4004 H14 Aluminium Brazing Sheet is a composite sheet that features the properties of 4004 and 3003 alloys in H14 temper. This product offers excellent thermal conductivity, strength, and corrosion resistance, making it ideal for use in automotive, HVAC, and other applications where reliable brazed joints are essential.

Brazing Material 4004 Aluminum Mechanical Properties

| Property | Value and Unit |

| Elastic (Young's, Tensile) Modulus | 71 GPa (10 x 10⁶ psi) |

| Elongation at Break | 2.4 % |

| Fatigue Strength | 42 MPa (6.1 x 10³ psi) |

| Poisson's Ratio | 0.33 |

| Shear Modulus | 27 GPa (3.9 x 10⁶ psi) |

| Shear Strength | 63 MPa (9.1 x 10³ psi) |

| Tensile Strength: Ultimate (UTS) | 110 MPa (16 x 10³ psi) |

| Tensile Strength: Yield (Proof) | 60 MPa (8.7 x 10³ psi) |

Brazing Material 4004 Aluminum Thermal Properties

| Property | Value and Unit |

| Brazing Temperature | 590 to 600 °C (1090 to 1120 °F) |

| Latent Heat of Fusion | 540 J/g |

| Maximum Temperature: Mechanical | 160 °C (320 °F) |

| Melting Completion (Liquidus) | 600 °C (1100 °F) |

| Melting Onset (Solidus) | 560 °C (1040 °F) |

| Specific Heat Capacity | 910 J/kg-K (0.22 BTU/lb-°F) |

| Thermal Conductivity | 130 W/m-K (78 BTU/h-ft-°F) |

| Thermal Expansion | 22 µm/m-K |

Brazing Material 4004 Aluminum Electrical Properties

| Property | Value and Unit |

| Electrical Conductivity: Equal Volume | 33 % IACS |

| Electrical Conductivity: Equal Weight (Specific) | 120 % IACS |

Otherwise Unclassified Properties

| Property | Value and Unit |

| Base Metal Price | 9.5 % relative |

| Density | 2.6 g/cm³ (160 lb/ft³) |

| Embodied Carbon | 8.0 kg CO₂/kg material |

| Embodied Energy | 150 MJ/kg (63 x 10³ BTU/lb) |

| Embodied Water | 1070 L/kg (130 gal/lb) |

Common Calculations

| Property | Value and Unit |

| Resilience: Ultimate (Unit Rupture Work) | 2.3 MJ/m³ |

| Resilience: Unit (Modulus of Resilience) | 25 kJ/m³ |

| Stiffness to Weight: Axial | 15 points |

| Stiffness to Weight: Bending | 54 points |

| Strength to Weight: Axial | 12 points |

| Strength to Weight: Bending | 20 points |

| Thermal Diffusivity | 58 mm²/s |

| Thermal Shock Resistance | 5.1 points |

4004 Aluminum Alloy Composition

| Element | Percentage by Weight (%) |

| Aluminum (Al) | 86 to 90 |

| Silicon (Si) | 9.0 to 10.5 |

| Magnesium (Mg) | 1.0 to 2.0 |

| Iron (Fe) | 0 to 0.8 |

| Copper (Cu) | 0 to 0.25 |

| Zinc (Zn) | 0 to 0.2 |

| Manganese (Mn) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

All values represent weight percentages and are within the specified ranges permitted by applicable standards.

Applications of 4004 Brazing Aluminum Foil Strip Coil

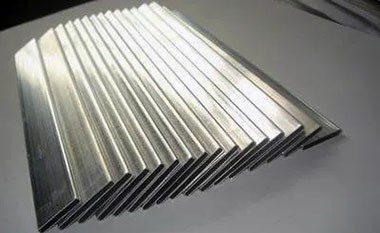

The 4004 brazing aluminum foil strip coil is typically rolled together with 3003 aluminum alloy to form aluminum alloy composite materials.

The 4004 brazing aluminum foil strip coil is primarily used for brazing aluminum alloy sheets, which are widely applied in radiators or heat exchangers for automobiles, air conditioning, oxygen generators, and cryogenic equipment.

- Automotive Industry: In automotive radiators and heat exchangers, the 4004 alloy is widely used in cooling systems due to its excellent thermal conductivity and corrosion resistance.

- Air Conditioning Equipment: As a heat exchanger material for air conditioners, the 4004 alloy helps improve system efficiency and durability.

- Oxygen Generators and Cryogenic Equipment: Particularly in air separation equipment like oxygen generators, the 4004 aluminum foil strip is used to manufacture large heat exchangers, which are required to operate stably under high-pressure conditions, ensuring reliable heat exchange performance.