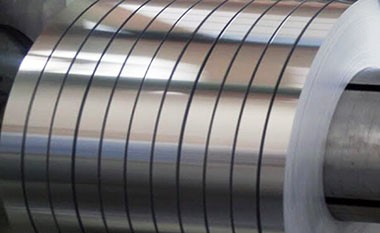

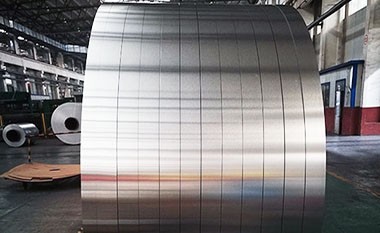

4045 brazing aluminum foil strip coil

4045 aluminum brazing foil strip coil is an aluminum-silicon alloy, commonly used as a brazing filler material for joining other alloys or on its own as a brazing material.

4045 aluminum brazing foil strip coil is a widely used aluminum-silicon alloy material, extensively applied in aluminum alloy brazing processes.

The 4045 aluminum brazing material is primarily composed of aluminum and silicon, typically containing about 12% to 15% silicon. This composition provides the 4045 alloy with excellent flow and wetting properties during brazing, effectively filling the joint.

During the brazing process, the 4045 aluminum foil serves as a filler material, melting and bonding with the base aluminum alloy at high temperatures. Its lower melting point (approximately 580°C to 650°C) allows for strong joints to be formed at reduced temperatures.

After brazing, 4045 aluminum brazing materials typically exhibit excellent mechanical properties, including good tensile strength and fatigue resistance. Additionally, the corrosion resistance of the brazed joints is ensured, making it suitable for applications in various harsh environments.

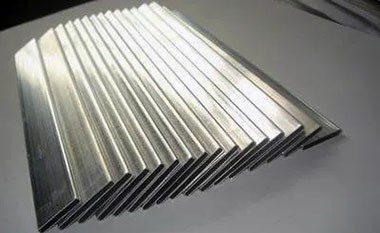

4045 aluminum alloy brazing strip, also known as aluminum alloy brazing foil, is commonly used in vacuum brazing, flame brazing, high-frequency brazing, and other methods for welding aluminum alloys, in conjunction with aluminum brazing flux (or aluminum welding filler), to enhance the welding effect. Due to the similar melting point of the 4045 brazing material and the workpiece, its temperature control requirements are more precise compared to other brazing materials. This aluminum alloy belongs to the 4000 series, with silicon as the primary alloying element, and is suitable for welding aluminum alloys in non-heat-treated or solution-treated states.

4045 aluminum foil is widely used for welding aluminum alloys such as 3004, 5005, 6063, and 6951, achieving high-quality welded joints.

In European standards, it will be given as EN AW-4045. BAlSi-5 is the AWS designation. AlSi10 is the EN chemical designation. Additionally, the UNS number is A94045.

Advantages of 4045 Brazing Aluminum Foil Strip Coil

- Strength and Toughness: The strength and toughness of the 4045 alloy maintain good structural performance after welding, making it suitable for high-strength applications.

- Good Weldability: Its excellent weldability reduces defects during the welding process, increasing production efficiency.

Applications of 4045 Brazing Aluminum Foil Strip Coil

The 4045 aluminum brazing foil strip coil is suitable for brazing various aluminum alloys, including common alloys like 6061, 6063, and 7075. It is typically used in the manufacturing of radiators, heat exchangers, and automotive parts that require high strength and good corrosion resistance.

- Brazing Surface: 4045 is often used as a brazing surface, effectively bonding with other aluminum alloys (such as 4047, 6061, 7075) to form strong and reliable connections.

- Brazing Material: In some applications, the 4045 alloy can be used independently as a brazing material. It is particularly useful for connecting different types of aluminum alloys, especially in the manufacturing of radiators, air conditioning components, and automotive parts.

4045 coil brazing is widely used in aluminum automotive radiator cooling systems, automotive air conditioning lines, condensers, evaporators, automotive aluminum heater cores, oil coolers, intercoolers, and commercial and residential aluminum brazing microchannel heat exchangers, as well as air-cooled pipes.

Brazing Aluminum 4045 Mechanical Properties

| Property | Value |

| Elastic (Young's, Tensile) Modulus | 71 GPa (10 x 10⁶ psi) |

| Elongation at Break | 2.3 % |

| Fatigue Strength | 45 MPa (6.5 x 10³ psi) |

| Poisson's Ratio | 0.33 |

| Shear Modulus | 27 GPa (3.9 x 10⁶ psi) |

| Shear Strength | 69 MPa (10 x 10³ psi) |

| Tensile Strength: Ultimate (UTS) | 120 MPa (17 x 10³ psi) |

| Tensile Strength: Yield (Proof) | 64 MPa (9.3 x 10³ psi) |

Brazing Aluminum 4045 Thermal Properties

| Property | Value |

| Brazing Temperature | 590 to 600 °C (1090 to 1120 °F) |

| Latent Heat of Fusion | 540 J/g |

| Maximum Temperature: Mechanical | 160 °C (320 °F) |

| Melting Completion (Liquidus) | 600 °C (1110 °F) |

| Melting Onset (Solidus) | 580 °C (1070 °F) |

| Specific Heat Capacity | 900 J/kg-K (0.22 BTU/lb-°F) |

| Thermal Conductivity | 170 W/m-K (99 BTU/h-ft-°F) |

| Thermal Expansion | 21 µm/m-K |

Brazing Aluminum 4045 Electrical Properties

| Property | Value |

| Electrical Conductivity: Equal Volume | 45 % IACS |

| Electrical Conductivity: Equal Weight (Specific) | 160 % IACS |

Brazing Aluminum 4045 Otherwise Unclassified Properties

| Property | Value |

| Base Metal Price | 9.5 % relative |

| Density | 2.6 g/cm³ (160 lb/ft³) |

| Embodied Carbon | 7.8 kg CO₂/kg material |

| Embodied Energy | 150 MJ/kg (63 x 10³ BTU/lb) |

| Embodied Water | 1070 L/kg (130 gal/lb) |

Brazing Aluminum 4045 Common Calculations

| Property | Value |

| Resilience: Ultimate (Unit Rupture Work) | 2.4 MJ/m³ |

| Resilience: Unit (Modulus of Resilience) | 29 kJ/m³ |

| Stiffness to Weight: Axial | 15 points |

| Stiffness to Weight: Bending | 54 points |

| Strength to Weight: Axial | 13 points |

| Strength to Weight: Bending | 21 points |

| Thermal Diffusivity | 74 mm²/s |

| Thermal Shock Resistance | 5.7 points |

Brazing Aluminum 4045 Alloy Composition

| Element | Range (%) |

| Aluminum (Al) | 87.4 to 91 |

| Silicon (Si) | 9.0 to 11 |

| Iron (Fe) | 0 to 0.8 |

| Copper (Cu) | 0 to 0.3 |

| Titanium (Ti) | 0 to 0.2 |

| Zinc (Zn) | 0 to 0.1 |

| Manganese (Mn) | 0 to 0.050 |

| Magnesium (Mg) | 0 to 0.050 |

| Residuals | 0 to 0.15 |