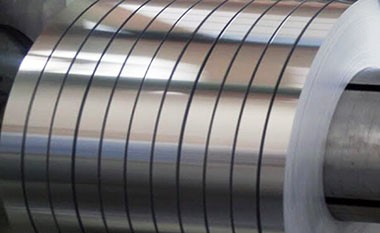

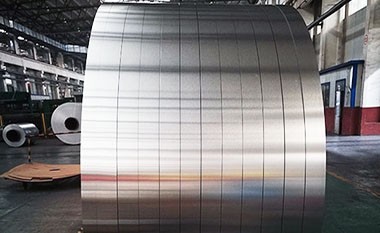

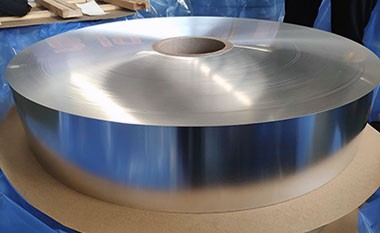

4047 brazing aluminum foil strip coil

What is 4047 aluminium?

4047 aluminium alloy is a high-silicon content aluminium-silicon brazing or filler alloy, primarily used in welding and manufacturing. Its silicon content ranges from 11-13%, giving 4047 excellent fluidity and corrosion resistance, making it particularly suitable for high-temperature environments. Compared to AL4043 alloy, 4047 has a higher silicon content, which effectively reduces shrinkage and hot cracking during welding.

4047 aluminum is a 4000 series aluminum alloy. The main alloying addition is silicon. The properties quoted apply to the as-fabricated state (no tempering or treatment).

4047 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-4047. BAlSi-4 is the AWS designation. Additionally, the UNS number is A94047.

Characteristics of 4047 brazing aluminum foil strip coil

1. Good corrosion resistance

The high silicon content of 4047 alloy exhibits exceptional corrosion resistance, allowing it to withstand oxidation and corrosion in various environments. It is especially suitable for use in humid or chemically corrosive environments, commonly found in automotive, aerospace, and marine applications. This corrosion resistance not only extends its service life but also reduces maintenance and replacement frequency.

2. High fluidity

In the molten state, 4047 alloy demonstrates good fluidity, meaning it can easily fill welding gaps. This characteristic allows 4047 alloy to better penetrate complex joint surfaces during welding, ensuring the integrity and strength of the weld, thereby enhancing the quality and reliability of the welded joints.

3. High-temperature applicability

The 4047 alloy maintains good performance at high temperatures, making it suitable for applications such as engine blocks and other high-temperature environments. This high-temperature resistance allows it to perform excellently in thermal cycling and thermal stress conditions, enabling stable operation under heavy loads.

4. Lower melting point and narrow solidification range

The relatively low melting point of 4047 alloy allows it to melt and solidify quickly during welding, reducing the heat input's impact on the base material. The narrow solidification range means that during welding, the alloy can form a stable weld joint more quickly, decreasing the risk of welding distortion and improving welding efficiency.

5. Good thermal and electrical conductivity

4047 alloy has excellent thermal and electrical conductivity, making it perform well in applications such as electronic devices and heat exchangers, which require rapid heat dissipation or conductivity. This thermal conductivity ensures that devices can effectively dissipate heat under heavy workloads, extending their service life.

6. Lightweight and durable

As an aluminium alloy, 4047 is lightweight, significantly reducing the overall weight of equipment compared to other metal materials. This lightweight characteristic is especially important in industries like aerospace and automotive, helping to improve fuel efficiency and lower transportation costs. Additionally, the durability of 4047 alloy ensures its long-term use in harsh environments, reducing replacement frequency.

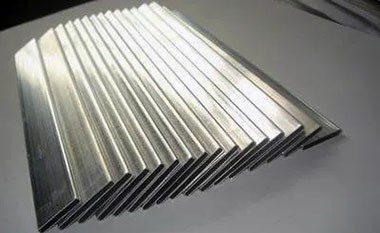

4047 Brazing Aluminum product forms

| Form | Min Size | Max Size | Typical Stock Size |

| Foil | 0.003" Thk | 0.020" Thk | 4-12" W X 12-72" L |

| Sheet | 0.003" Thk | 4" Thk | 0.190" Thk X 24" X 72" |

| Strip | 0.003" Thk | 4" Thk | 4-12" W x 12-72" L |

| Plate | 0.188" Thk | 4" Thk | 0.190" Thk X 24" X 72" |

| Rod / Round Bar / Wire | 0.010" Dia | 6" Dia | 72" LONG |

4047 brazing aluminum foil strip coil materia performance

| Performance index of air heating element materia | |||||||

| Alloy | Temper | Thickness (mm) | Tolerance (mm) | Clad rate(%) | Mechanica property | ||

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation Min.(%) | |||||

| 3003 | O | 0.2~0.30 | ±0.01 | None | 100~150 | ≥45 | 15 |

| 3003 | H16 | 0.5~0.70 | ±0.02 | None | 150~210 | ≥120 | 1 |

| 4047 | H18 | 0.05~0.1 | ±0.005 | None | ≥200 | ≥170 | 0.5 |

| 4045 | H18 | 0.05~0.1 | ±0.005 | None | ≥195 | ≥165 | 0.5 |

| 4A13 | H18 | 0.05~0.1 | ±0.005 | None | ≥190 | ≥16 | 0.5 |

| 4104 | H18 | 0.05~0.1 | ±0.005 | None | ≥220 | ≥190 | 0.5 |

HC Aluminum is a global leader in 4047 aluminum materials, offering 4047 aluminum foil with thicknesses ranging from 0.003 inches to 0.1875 inches.

4047 aluminum typically meets the requirements of AMS 4185, QQ-B-365, HMS 2273, Mil-B-20148, alloy 718, BALSi4, AWS5.8, UNS A94047, ASTM-B-247, AA4047, EN AW-4047A, and EN AW-Al Si12(A).

Applications of 4047 Brazing Aluminum Foil Strip Coil

1. Automotive Industry

4047 brazing aluminum is widely used in the automotive industry for manufacturing and repairing engine blocks and other high-temperature components. Its high-temperature suitability and excellent corrosion resistance ensure stable performance in engine environments, enhancing the reliability and safety of vehicles. Additionally, the high fluidity of the 4047 alloy effectively fills complex weld gaps during welding, improving weld quality.

2. Welding Filler Material

The 4047 alloy serves as a welding filler wire suitable for various applications requiring high fluidity in welding. Its excellent flow characteristics and low melting point make the welding process smoother, effectively reducing defects such as porosity and cracks. This feature makes the 4047 alloy widely used in welding processes, especially in situations where precise control over joint quality is essential.

3. Leak-proof Joints

The 4047 alloy performs exceptionally well in components requiring leak-proof connections. Its excellent sealing performance ensures the reliability of joints, making it widely applicable in liquid and gas transmission pipelines, cooling systems, and more. This leak-proof capability is crucial for maintaining the effectiveness and safety of systems.

4047 brazing aluminum is also suitable for the manufacturing and maintenance of various similar equipment, including aerospace, electronic devices, and heat exchangers.

4047 Brazing Aluminum Mechanical Properties

| Property | Value and Units |

| Elastic (Young's, Tensile) Modulus | 72 GPa (10 x 10^6 psi) |

| Elongation at Break | 3.4% |

| Fatigue Strength | 45 MPa (6.6 x 10^3 psi) |

| Poisson's Ratio | 0.33 |

| Shear Modulus | 27 GPa (3.9 x 10^6 psi) |

| Shear Strength | 69 MPa (10 x 10^3 psi) |

| Tensile Strength: Ultimate (UTS) | 120 MPa (17 x 10^3 psi) |

| Tensile Strength: Yield (Proof) | 64 MPa (9.2 x 10^3 psi) |

4047 Brazing Aluminum Thermal Properties

| Property | Value and Units |

| Brazing Temperature | 580 to 600 °C (1080 to 1120 °F) |

| Latent Heat of Fusion | 570 J/g |

| Maximum Temperature: Mechanical | 160 °C (320 °F) |

| Melting Completion (Liquidus) | 580 °C (1080 °F) |

| Melting Onset (Solidus) | 580 °C (1070 °F) |

| Specific Heat Capacity | 900 J/kg-K (0.22 BTU/lb-°F) |

| Thermal Conductivity | 130 W/m-K (77 BTU/h-ft-°F) |

| Thermal Expansion | 21 µm/m-K |

4047 Brazing AluminumElectrical Properties

| Property | Value and Units |

| Electrical Conductivity (Equal Volume) | 33% IACS |

| Electrical Conductivity (Equal Weight) | 120% IACS |

Common Calculations

| Calculation | Value and Units |

| Resilience: Ultimate (Unit Rupture Work) | 3.5 MJ/m³ |

| Resilience: Unit (Modulus of Resilience) | 28 kJ/m³ |

| Stiffness to Weight: Axial | 16 points |

| Strength to Weight: Axial | 13 points |

| Thermal Diffusivity | 59 mm²/s |

| Thermal Shock Resistance | 5.6 points |

4047 Brazing Aluminum Alloy Composition

| Element | Percentage |

| Aluminum (Al) | 85.3 to 89 |

| Silicon (Si) | 11 to 13 |

| Iron (Fe) | 0 to 0.8 |

| Copper (Cu) | 0 to 0.3 |

| Zinc (Zn) | 0 to 0.2 |

| Manganese (Mn) | 0 to 0.15 |

| Magnesium (Mg) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

Aluminum 4047 Stock Sizes

Foil/Sheet/Strip/Plate

| Product | Thickness | Width | Length |

| 0.003" Thk x 4"w x 24" Lg 4047 Aluminum | 0.003" | 4" | 24" |

| 0.003" Thk x 6" W x 24" Lg 4047 Aluminum | 0.003" | 6" | 24" |

| 0.005" Thk x 6"w x 24" Lg 4047 Aluminum | 0.005" | 6" | 24" |

| 0.008" Thk x 6"w x 12" Lg 4047 Aluminum | 0.008" | 6" | 12" |

| 0.010" Thk x 6"w x 24" Lg 4047 Aluminum | 0.010" | 6" | 24" |

| 0.010" Thk x 6"w x 36" Lg 4047 Aluminum | 0.010" | 6" | 36" |

| 0.010" Thk x 12" x 36" Lg 4047 Aluminum | 0.010" | 12" | 36" |

| 0.012" Thk x 6"w x 36" Lg 4047 Aluminum | 0.012" | 6" | 36" |

| 0.015" Thk x 6"w x 24" Lg 4047 Aluminum | 0.015" | 6" | 24" |

| 0.015" Thk x 12"w x 36" Lg 4047 Aluminum | 0.015" | 12" | 36" |

| 0.020" Thk x 0.20"w x 200" Lg 4047 Aluminum Coil | 0.020" | 0.20" | 200" Coil |

| 0.020" Thk x 12"w x 72" Lg 4047 Aluminum | 0.020" | 12" | 72" |

| 0.025" Thk x 3"w x 24" Lg 4047 Aluminum | 0.025" | 3" | 24" |

| 0.030" Thk x 12"w x 72" Lg 4047 Aluminum | 0.030" | 12" | 72" |

| 0.040" Thk x 12"w x 72" Lg 4047 Aluminum | 0.040" | 12" | 72" |

| 0.045" Thk x 6"w x 36" Lg 4047 Aluminum | 0.045" | 6" | 36" |

| 0.050" Thk x 12"w x 72" Lg 4047 Aluminum | 0.050" | 12" | 72" |

| 0.060" Thk x 12"w x 72" Lg 4047 Aluminum | 0.060" | 12" | 72" |

| 0.080" Thk x 12"w x 40" Lg 4047 Aluminum | 0.080" | 12" | 40" |

| 0.080" Thk x 12"w x 72" Lg 4047 Aluminum | 0.080" | 12" | 72" |

| 0.090" Thk x 12"w x 36" Lg 4047 Aluminum | 0.090" | 12" | 36" |

| 0.125" Thk x 12"w x 72" Lg 4047 Aluminum | 0.125" | 12" | 72" |

| 0.160" Thk x 4.5"w x 6" Lg 4047 Aluminum | 0.160" | 4.5" | 6" |

| 0.190" Thk x 24"w x 12" Lg 4047 Aluminum | 0.190" | 24" | 12" |

| 0.190" Thk x 24"w x 72" Lg 4047 Aluminum | 0.190" | 24" | 72" |

| 0.250" Thk x 8"w x 12" Lg 4047 Aluminum | 0.250" | 8" | 12" |

| 0.500" Thk x 6"w x 12" Lg 4047 Aluminum | 0.500" | 6" | 12" |

| 0.500" Thk x 12"w x 36" Lg 4047 Aluminum | 0.500" | 12" | 36" |

| 0.750" Thk x 12"w x 32" Lg 4047 Aluminum | 0.750" | 12" | 32" |

| 0.800" Thk x 3.5"w x 47" Lg 4047 Aluminum | 0.800" | 3.5" | 47" |

| 1.000" Thk x 12"w x 36" Lg 4047 Aluminum | 1.000" | 12" | 36" |

| 1.375" Thk x 1.750"w x 3.600" Lg 4047 Aluminum | 1.375" | 1.750" | 3.600" |

| 1.500" Thk x 12"w x 36" Lg 4047 Aluminum | 1.500" | 12" | 36" |

Related Questions about 4047 Brazing Aluminum Foil Strip Coil

What is Filler Metal for Aluminum Brazing?

Filler metal for aluminum brazing is an alloy used to fill the gap between two aluminum pieces during the brazing process. It melts at a lower temperature than aluminum, allowing it to flow into the joint and create a strong bond when cooled.

What is Aluminum Brazing Sheet?

Aluminum brazing sheet is a type of aluminum material that has a layer of filler metal bonded to its surface. It is designed for brazing applications, making it easier to join aluminum components, especially in heat exchangers and automotive parts.