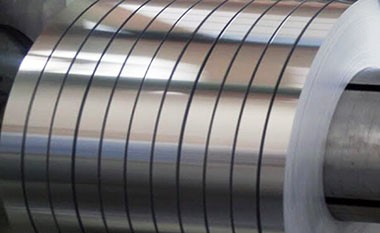

4104/3003/4104 Aluminum Clad Brazing Sheet Strip

4104/3003/4104 aluminum clad brazing sheet strip is a material composed of different aluminum alloy layers, commonly used in aerospace, transportation, construction, and other fields.

The main characteristics of the 4104/3003/4104 aluminum clad brazing sheet strip are that it combines the advantages of different aluminum alloys, offering good mechanical properties, corrosion resistance, and weldability.

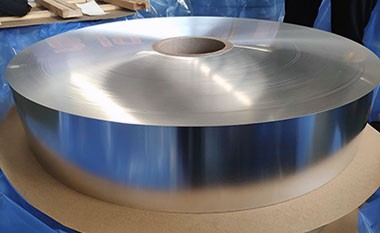

Structure of 4104/3003/4104 Aluminum Clad Brazing Sheet Strip

Composite Layers

- Outer and inner layers: 4104 aluminum alloy, serving as the welding layer, provides excellent weldability and fluidity.

- Middle layer: 3003 aluminum alloy, serving as the substrate, offers excellent mechanical strength and corrosion resistance.

Layer Structure

The structure of this composite material features a three-layer design, with the outer and inner layers made of 4104 alloy and the middle layer made of 3003 alloy. This structure ensures good bonding quality and strength during the welding process.

- 4104 aluminum alloy: Typically used for the surface layer of the composite material, it possesses good weldability and corrosion resistance, making it suitable for high-temperature environments.

- 3003 aluminum alloy: As the middle layer, 3003 aluminum alloy offers excellent formability and weldability, effectively enhancing the overall performance of the composite material.

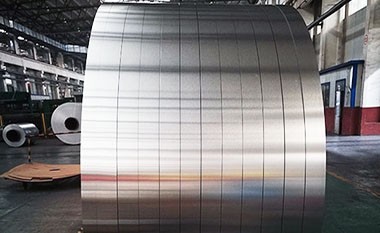

Specifications of 4104/3003/4104 Aluminum Clad Brazing Sheet Strip

| Alloy | 4104/3003/4104 |

| Temper | O |

| Thickness | 0.5-20mm |

| Width | 500-1500mm |

| Length | Up to 6000mm |

| MOQ | 2500KGS |

| T Standard | GB/3880-2006, GB/3880-2012 |

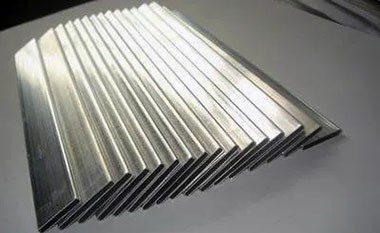

| Alloy | Temper | Thickness (mm) | Tolerance(mm) | Clad rate(%) |

| 4104/3003/4104 | H14 | 0.6~0.8 | ±0.02 | 13~17 |

| 1.2~8.3 | ±0.03 | 8~12 |

HC Aluminum offers brazing aluminum: 4343/3003/4343, 4045/3003/4045, 4343/3003, 4104/3003/4104, 4045/3003/7072, etc.

Mechanical Properties of 4104/3003/4104 Aluminum Clad Brazing Sheet Strip

- Tensile Strength: The 4104/3003/4104 clad brazing sheet strip has excellent tensile strength, typically ranging from 180 to 200 MPa, suitable for high-pressure applications.

- Elongation: This material exhibits good elongation properties, ensuring it does not suffer brittle fracture under stress.

- Yield Strength: ≥160 MPa, meeting the needs for various structural components.

Advantages of 4104/3003/4104 Aluminum Clad Brazing Sheet Strip

1. Excellent Weldability

Low Melting Point: The relatively low melting point of 4104 aluminum alloy allows brazing at lower temperatures. This not only improves welding efficiency but also reduces the heat-affected zone during welding, thereby minimizing deformation and stress concentration.

2. Good Mechanical Properties

Enhanced Strength: The addition of 3003 aluminum alloy increases the overall strength of the composite material, ensuring outstanding performance under mechanical loads. The tensile and yield strengths of 3003 alloy make the composite material more reliable for structural applications.

3. Excellent Thermal Conductivity

High Thermal Conductivity: The thermal conductivity of aluminum alloy materials is superior to that of many other metals, making the 4104/3003/4104 composite particularly suitable for thermal management applications such as heat exchangers, effectively improving heat exchange efficiency and reducing energy consumption.

Thermal Management Applications: In devices requiring rapid heat dissipation or efficient heat exchange, such as automotive radiators and air conditioning systems, using this composite material can significantly enhance performance.

4. Lightweight Characteristics

Low Density: The density of aluminum alloys is much lower than that of steel, allowing the 4104/3003/4104 composite to significantly reduce overall weight while maintaining strength.

Applications of 4104/3003/4104 Aluminum Clad Brazing Sheet Strip

1. Automotive Industry

Radiators: The 4104/3003/4104 aluminum clad brazing sheet strip is commonly used in the manufacture of automotive radiators due to its excellent thermal conductivity and corrosion resistance, effectively enhancing heat dissipation efficiency.

Cooling Systems: In automotive cooling systems, the composite aluminum sheet can be used to manufacture components such as coolers and oil coolers, ensuring the engine operates at optimal temperatures.

2. Air Conditioning and Refrigeration Equipment

Heat Exchangers: This material is widely used in heat exchangers for air conditioning and refrigeration equipment, as its superior thermal conductivity enhances heat exchange efficiency and reduces energy consumption.

Condensers: The 4104/3003/4104 aluminum clad brazing sheet is used as the primary material for condensers, ensuring efficient operation and durability of the equipment.

3. Electronic Devices

Heat Sinks: In electronic devices, this composite material can be used to manufacture heat sinks, helping to dissipate heat from electronic components and extending the lifespan of the equipment.

Battery Cooling Systems: In electric vehicles and other battery systems requiring efficient heat dissipation, the composite aluminum sheet can be used to manufacture cooling components.

4. Aerospace

Heat Exchangers: In spacecraft, the 4104/3003/4104 aluminum clad brazing sheet can be used in heat exchangers, ensuring stability and reliability of equipment in extreme environments.

5. Home Appliance Industry

Water Heaters: This composite material can be used in heat exchangers for water heaters, improving thermal efficiency and durability.

Refrigerators: Using 4104/3003/4104 aluminum clad brazing sheet in the condenser system of refrigerators can enhance cooling efficiency and reduce energy consumption.