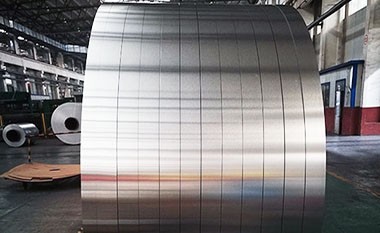

4104 brazing aluminum foil strip coil

4104 brazing aluminum foil strip rolls are essential materials in the production process of aluminum heat exchangers, mainly used in vacuum welding processes. As a brazing filler, its primary component is aluminum alloy, which has a relatively high melting point (above 450°C). During welding, it is typically necessary to increase the temperature by 25°C to 60°C above the melting point of the filler to ensure that it can adequately fill the welding gaps.

4104 aluminum is a 4000-series aluminum alloy. The main alloying addition is silicon. Cited properties are appropriate for the as-fabricated (no temper or treatment) condition.

AL 4104 is a widely used filler metal for joining aluminum and aluminum alloys. To ensure joint integrity, its solution temperature must be below the solidus line of the brazing alloy during the heat treatment process.

AL 4104 has a lower melting point and a narrower melting range, making it highly suitable for brazing aluminum alloys. Additionally, compared to other aluminum filler metals, AL 4104 has a higher silicon content, which enhances flowability and reduces shrinkage. Using AL 4104 also significantly reduces the risk of thermal cracking during the brazing process. Furthermore, the increased magnesium content helps prevent oxidation of the brazed surface during heating.

Specifications for AL 4104 Alloy

4104 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-4104. BAlSi-11 is the AWS designation. AlSi10MgBi is the EN chemical designation. Additionally, the UNS number is A94104.

| Specification | Details |

| UNS | A94104 |

| AWS | A5.8/A5.8M BAlSi-11 |

| Aluminum Association | 4104 |

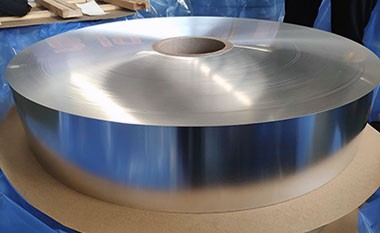

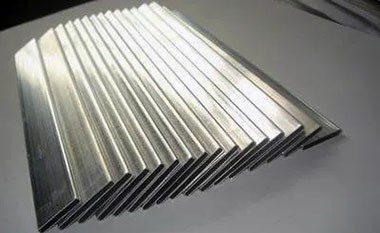

Available Forms for AL 4104 Alloy

| Form | Details |

| Wire | Available in various diameters and lengths. |

| Strip | Customizable thickness and width. |

| Specialty Preforms | Customized forms for unique applications. |

| Powder | For use in powder metallurgy and coatings. |

Characteristics of Brazing Material 4104 Aluminum

Chemical Composition

Si Content: The silicon content of 4104 aluminum alloy is between 9.0% and 10.5%. This relatively high silicon content gives it a lower melting point, thereby improving the fluidity and filling ability during the brazing process.

Melting Point

Melting Point: The melting point of 4104 aluminum alloy exceeds 450°C. During brazing, a temperature 25°C to 60°C higher than its melting point is typically chosen to ensure the filler can adequately fill the welding gaps, achieving good bonding effects.

Physical Properties

- Fluidity: Excellent fluidity allows 4104 aluminum alloy to flow smoothly at high temperatures, aiding in the filling of weld joints.

- Wetting Ability: Its good wettability enhances bonding strength with the base material, ensuring the reliability of the weld.

- Gap Filling Ability: 4104 brazing aluminum foil strip rolls possess outstanding gap-filling capability, effectively filling gaps created during the welding process.

4104 brazing aluminum foil strip coil Chemical Composition

| 4104 Chemical Composition(%) | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Bi | Alu |

| 9.0-10.5 | <0.8 | <0.25 | <0.10 | 1.0-2.0 | - | <0.20 | - |

0.02- 0.20 |

Remainder |

Brazing Material 4104 Aluminum Mechanical Properties

| Property | Value and Units |

| Elastic (Young's, Tensile) Modulus | 71 GPa (10 x 10⁶ psi) |

| Elongation at Break | 2.4% |

| Fatigue Strength | 42 MPa (6.1 x 10³ psi) |

| Poisson's Ratio | 0.33 |

| Shear Modulus | 27 GPa (3.9 x 10⁶ psi) |

| Shear Strength | 63 MPa (9.1 x 10³ psi) |

| Tensile Strength: Ultimate (UTS) | 110 MPa (16 x 10³ psi) |

| Tensile Strength: Yield (Proof) | 60 MPa (8.7 x 10³ psi) |

Brazing Material 4104 Aluminum Thermal Properties

| Property | Value and Units |

| Brazing Temperature | 590 to 600 °C (1090 to 1120 °F) |

| Latent Heat of Fusion | 540 J/g |

| Maximum Temperature: Mechanical | 160 °C (320 °F) |

| Melting Completion (Liquidus) | 600 °C (1100 °F) |

| Melting Onset (Solidus) | 560 °C (1040 °F) |

| Specific Heat Capacity | 900 J/kg-K (0.22 BTU/lb-°F) |

| Thermal Conductivity | 130 W/m-K (78 BTU/h-ft-°F) |

| Thermal Expansion | 22 µm/m-K |

Brazing Material 4104 Aluminum Electrical Properties

| Property | Value and Units |

| Electrical Conductivity: Equal Volume | 33% IACS |

| Electrical Conductivity: Equal Weight (Specific) | 120% IACS |

Brazed Joint Performance

The performance of brazed joints is influenced by various factors, including the characteristics of the base material, joint design, and the metallurgical interaction between the base material and the filler metal. Studies have shown that optimal joint strength for aluminum brazed assemblies can be achieved when the joint gap is controlled within the range of 0.003-0.005 inches (0.076-0.127 mm).

Advantages of 4104 Brazing Aluminum Foil Strip Coil

1. Welding Strength

4104 aluminum alloy exhibits good welding strength during the welding process. As a filler layer, it can achieve effective welding at lower temperatures, ensuring the structural integrity and durability of the welded area. After welding, the bonding zone formed by 4104 aluminum alloy has high tensile and shear strength, preventing the overall structure from easily breaking or detaching under external forces. This excellent welding performance makes it particularly important in applications such as automotive and water cooling systems and other heat exchangers, meeting the demands of high stress and high-temperature environments.

2. Corrosion Resistance

The corrosion resistance of 4104 aluminum alloy significantly enhances the overall corrosion resistance of composite aluminum panels. Aluminum alloys have good oxidation resistance, allowing them to resist chemical corrosion and oxidation reactions in various environments, especially in humid or saline conditions. By using 4104 aluminum alloy in composite materials, the product's lifespan can be effectively extended, maintenance frequency reduced, and long-term usage costs lowered. This is particularly important for automotive and industrial equipment, which are often exposed to harsh environmental conditions.

3. Composite Materials

4104 brazing aluminum foil strip rolls are commonly used as a cladding layer for composite aluminum panels, providing excellent bonding performance. Due to its good welding characteristics, 4104 aluminum alloy can form strong bonds with other aluminum alloy materials or different substrates, enhancing the overall functionality of the materials. Composite aluminum panels not only incorporate the advantages of 4104 aluminum alloy but can also combine the properties of other materials, such as lightweight and high strength, resulting in final products that meet specific performance requirements while offering better overall performance. Additionally, composite structures can be designed according to different application needs to achieve better heat exchange effects and higher energy efficiency.

Applications of 4104 Brazing Aluminum Foil Strip Coil

4104 aluminum alloy brazing material, due to its excellent weldability, strength, and corrosion resistance, is widely used in the manufacturing of heat exchangers.

Automotive Radiator

4104 aluminum alloy composite panels have good thermal conductivity, effectively enhancing cooling efficiency, making them suitable for automotive radiator manufacturing.

Its corrosion resistance can extend the lifespan of the radiator and prevent leaks caused by coolant corrosion.

Automotive Air Conditioning Condenser

In automotive air conditioning systems, the lightweight characteristics of 4104 aluminum alloy help reduce overall vehicle weight, improving fuel efficiency.

The brazing properties of this material allow for a more compact structure in condensers, enhancing the overall performance of the air conditioning system.

Evaporator

Evaporators require good thermal conductivity and oxidation resistance, which 4104 aluminum alloy can meet, ensuring effective cooling.

In high-temperature and humid environments, the stability and durability of 4104 aluminum alloy also provide additional assurance.

Other Heat Exchangers

In addition to automotive applications, 4104 aluminum alloy can also be used in heat exchangers for other industries, such as industrial cooling systems and air conditioning equipment, meeting the needs of various working environments.