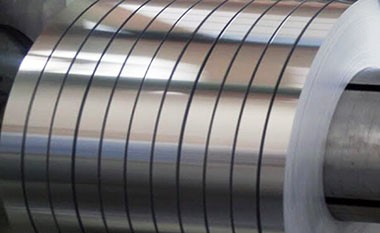

4343/3003/4045 Clad Aluminum Sheet Strip

The 4343/3003/4045 clad aluminum sheet strip is made from three layers of different aluminum alloy materials through a composite process. It is widely used in applications such as automotive radiator fins, evaporator fins, and oil cooler plates.

Composition of 4343/3003/4045 Clad Aluminum Sheet Strip

4343 Aluminum Alloy

Composition: The main components of 4343 aluminum alloy are aluminum, silicon, and small amounts of copper and magnesium. The silicon content typically ranges from 7% to 13%.

4343 aluminum alloy is usually used as the outer layer, offering good corrosion resistance and weldability. Its primary components are aluminum and silicon, which provide good flow properties and excellent weldability at high temperatures.

3003 Aluminum Alloy

Composition: The main components of 3003 aluminum alloy are aluminum and manganese, with manganese content typically between 1% and 1.5%.

As the middle layer, 3003 aluminum alloy is known for its excellent formability, weldability, and corrosion resistance. Its main components are aluminum and a small amount of manganese, which enhance its strength and oxidation resistance.

4045 Aluminum Alloy

Composition: The main components of 4045 aluminum alloy are aluminum and silicon, with silicon content typically ranging from 8% to 12%.

4045 aluminum alloy is usually used as the inner layer but can also serve as the outer layer, making it particularly suitable for high-temperature and high-pressure applications. It has good heat exchange properties, and its design allows for good bonding with 4343 aluminum alloy during welding.

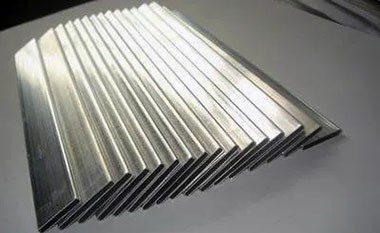

Specifications and Data Parameters of 4343/3003/4045 Clad Aluminum Sheet Strip

| Alloy | 4045/3003/4045 |

| Width | 0-1500MM |

| Thickness | 0.01-0.2 |

| Alloy | Temper | Thickness (mm) | Tolerance (mm) | Clad rate(%) | Mechanicaproperty | ||

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation Min.(%) | |||||

| 3003 | H14 | 0.08~0.12 | ±0.005 | None | 150~200 | ≥120 | 1 |

| Alloy | Temper | Thickness (mm) | Tolerance (mm) | Clad rate(%) | Mechanicaproperty | ||

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation Min.(%) | |||||

| 4343/3003/4343 | O | 0.4~8.3 | ±0.02 | 8~12 | 100~150 | ≥45 | 27 |

4343/3003/4045 Clad Aluminum Sheet Strip化学成分

Core Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | 0.1 | 0.05 | 0.03 |

| 3005 | 0.6 | 0.7 | 0.20-0.40 | 1.0-1.5 | 0.20-0.60 | 0.25 | - | 0.01 |

Cladding Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti |

| 4343 | 6.8-8.2 | 0.8 | 0.25 | 0.1 | - | 0.2 | - | 0.05 |

| 4045 | 9.0-11.0 | 0.8 | 0.3 | 0.05 | - | 0.2 | - | 0.2 |

| 4004 | 9.0-10.5 | 0.8 | 0.25 | 0.1 | 1.0-2.0 | 0.2 | - | 0.2 |

| 7072 | 0.7 | 0.1 | 0.1 | 0.1 | 0.8-1.3 | - | - | |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.5-1.0 | - | 0.03 |

4343/3003/4045 Clad Aluminum Sheet Strip Features

Excellent Thermal Conductivity

The 4343 alloy has exceptionally high thermal conductivity, making the clad aluminum sheet strip perform outstandingly in heat exchangers. Its good thermal conductivity effectively enhances heat exchange efficiency, ensuring rapid heat transfer and thereby improving the overall performance of the equipment. This is particularly important for applications that require efficient heat dissipation and thermal management.

Good Weldability

The combination of the 4343, 3003, and 4045 aluminum alloys ensures that the clad aluminum sheet strip is very reliable during welding and processing. The complementary characteristics of the different alloys guarantee the strength and durability of the weld joints, reducing the risk of defects during the welding process. This feature provides greater flexibility and adaptability during manufacturing.

Lightweight

The lightweight nature of aluminum alloy materials is a significant advantage, effectively reducing the overall weight of structures. This is especially important in industries such as aerospace and automotive, where weight reduction not only enhances transportation and operational convenience but also improves fuel efficiency and lowers energy consumption, thereby increasing overall economic benefits.

Corrosion Resistance

Aluminum alloys have good corrosion resistance, allowing them to withstand various harsh environmental influences. This makes the 4343/3003/4045 clad aluminum sheet strip perform excellently in chemical, marine, and other corrosive environments, extending its service life and reducing maintenance costs. Its corrosion resistance makes it an ideal choice for many industrial applications, especially in fields that require long-term stable performance.

4343/3003/4045 Clad Aluminum Sheet Strip Applications

Auto Radiator Clad Fin Stock (4343/3003/4045)

The clad fin stock is primarily used for automotive radiators, enhancing heat exchange efficiency by maximizing the cooling surface area.

The multi-layer structure of 4343/3003/4045 improves mechanical performance and corrosion resistance, which is crucial for automotive applications that frequently encounter liquids and high temperatures.

The high thermal conductivity of the 4343/3003/4045 clad aluminum sheet strip enables efficient heat transfer. The clad layer has excellent corrosion resistance, extending the lifespan of the radiator. It can also be easily shaped into the fin configurations required for radiators.

4343/3003/4045 Aluminum Sheet for Evaporator Fin

This sheet is composed of 4343 and 3003 alloy layers, with 4045 added to enhance adhesion. It is specifically designed for evaporator fins in air conditioning systems and refrigeration units, where efficient heat exchange is crucial.

The design of the 4343/3003/4045 aluminum sheet enables effective heat absorption and transfer, thereby improving the overall efficiency of the system.

4043/3003/4045 Aluminum Sheet for Oil Cooler Board

Specifically designed for oil coolers, efficient heat dissipation is critical for maintaining engine temperature. This structure supports applications in automotive and industrial machinery that require oil cooling to prevent overheating.