4343/3003/4343 Aluminum Clad Brazing Sheet Strip

4343/3003/4343 Aluminum Clad Brazing Sheet Strip is a multi-layer aluminum alloy composite material that exhibits excellent mechanical properties and good brazing performance.

What is aluminum brazing sheet?

Aluminum brazing sheet is a specialized type of aluminum material designed for use in brazing applications, particularly in the manufacturing of heat exchangers, such as radiators, condensers, evaporators, and other components that require efficient thermal conductivity. The sheet is typically made by bonding layers of aluminum alloys, often with a composition that enhances their brazing characteristics.

What is clad in brazing?

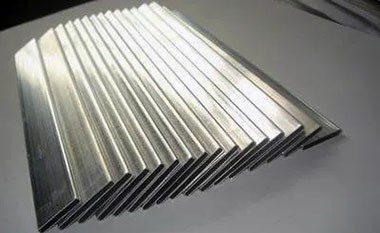

The core layer is made of 3003 or 3003 mod (modified version) as the skeleton layer, while the surface layer is clad with high-silicon 4343 alloy, providing better brazing and recrystallization performance.

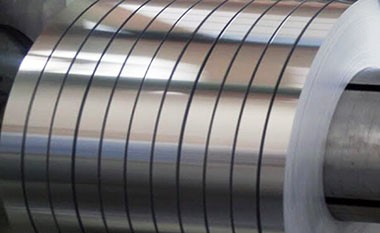

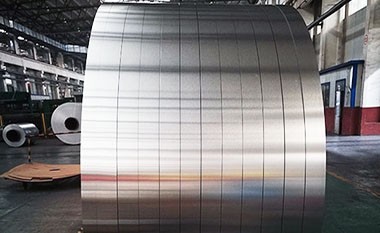

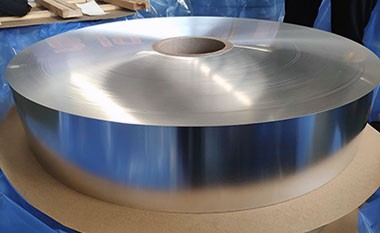

Based on the above detailed description, here is the 4343/3003/4343 aluminum clad brazing sheet strip.

4343/3003/4343 Aluminum Clad Brazing Sheet Strip Material Structure

- Surface Layer: Made of high-silicon 4343 aluminum alloy, with silicon content typically between 10-13%. This alloy has a lower melting point, allowing it to quickly melt during the brazing process to form high-quality joints. The high silicon content also enhances the material's oxidation resistance and corrosion resistance.

- Core Layer: Utilizes 3003 aluminum alloy or its modified version (3003 mod). The 3003 aluminum alloy contains 1.0% manganese, providing good weldability, formability, and corrosion resistance. The modified version (3003 mod) improves strength and toughness by adding small amounts of other elements, making it suitable for higher stress applications.

4343/3003/4343 Aluminum Clad Brazing Sheet Strip Specifications

| Specification | Details |

| Core Alloy | 3003 |

| Cladding Alloy | 4343 |

| Thickness | 1.0 mm - 3.0 mm |

| Width | 700 mm - 1200 mm |

| Temper | O, H14, H24 |

| Cladding Rate | 8%-12% per side or as requested by the customer |

| Delivery Time | 15-25 days after receiving your deposit |

| Packaging | Export standard wooden cases or pallets |

Advantages of 4343/3003/4343 Aluminum Clad Brazing Sheet Strip

- Excellent Brazing Performance: The low melting point and high fluidity of the 4343 alloy ensure welding quality, reducing defects, and making the brazing process smoother with stronger joints.

- Good Strength and Toughness: The 3003 core layer provides good mechanical strength, while the 4343 surface layer enhances overall toughness.

- Corrosion Resistance: The use of high-silicon alloy improves the corrosion resistance of the composite material, making it suitable for various harsh environments.

Brazing Performance of 4343/3003/4343 Aluminum Clad Sheet Strip

The excellent fluidity and wettability of the 4343 alloy allow it to effectively fill the weld seam during brazing, reducing welding defects such as porosity and inclusions. Its good wettability ensures the strength of the welded joint.

The 3003 aluminum alloy core layer provides a strong foundation capable of withstanding thermal stress during the welding process, ensuring the stability of the composite sheet in high-temperature environments.

Recrystallization Performance of 4343/3003/4343 Aluminum Clad Brazing Sheet Strip

The high-silicon alloy has excellent recrystallization performance, allowing the microstructure of the composite material to recover effectively after brazing, reducing brittleness and defects, and enhancing overall mechanical properties.

Control of the recrystallization process is crucial for the final product's strength and toughness, and the use of the 4343 alloy makes this process easier to achieve.

Applications of 4343/3003/4343 Aluminum Clad Brazing Sheet Strip

1. Heat Exchangers

Application Field: Mainly used for manufacturing various types of heat exchangers, such as automotive radiators, air conditioning condensers, and evaporators.

Advantages:

- Efficient Heat Exchange: Its composite structure and high thermal conductivity ensure excellent heat exchange performance, allowing for rapid heat transfer and improved cooling efficiency.

- Corrosion Resistance: The outer layer of 4343 aluminum alloy enhances the material's corrosion resistance, ensuring long-term use in humid and chemical environments without failure.

- High-Temperature Resistance: It maintains good performance in high-temperature environments, suitable for various industrial and commercial applications.

2. Electronic Devices

Application Field: Widely used in electronic thermal management, serving as heat sinks or cooling components commonly found in computers, communication equipment, and LED lighting.

Advantages:

- Excellent Heat Dissipation: High thermal conductivity allows the heat generated by electronic components to dissipate quickly, preventing overheating and enhancing the stability and lifespan of the devices.

- Lightweight and High Strength: Compared to other cooling materials, the lightweight nature of aluminum alloys helps reduce the overall weight of devices, facilitating mobility and installation.

- High Formability: Easily processed into various shapes to meet different cooling requirements.

3. Automotive Engineering

Application Field: Used in critical components such as engine oil coolers, intercoolers, and air conditioning systems.

Advantages:

- Enhanced Cooling Capacity: In automotive engines, the 4343/3003/4343 aluminum clad brazing sheet strip can effectively lower engine oil temperatures, improving engine performance and fuel efficiency.

- Increased Safety: Good heat dissipation reduces the risk of engine overheating, enhancing vehicle safety and reliability.

- Durability: The corrosion-resistant properties of aluminum alloys maintain stable performance in humid and high-temperature environments, ensuring long-term use.

Manufacturing Process of 4343/3003/4343 Aluminum Clad Sheet Strip

- Material Preparation: Select appropriate aluminum alloy materials and cut them to required sizes.

- Lamination: The 4343 alloy layer is laminated with the 3003 core layer using hot or cold pressing to form a composite sheet.

- Brazing: Brazing is performed under high-temperature conditions to ensure good bonding between layers.

- Post-treatment: May include heat treatment, surface treatment, etc., to further enhance the material's properties.