4343/3003/7072 Clad Aluminum Sheet Strip

4343/3003/7072 clad aluminum sheet strip is a composite material made up of different layers of aluminum alloys, primarily used in heat exchangers, coolers, automotive radiators, and other fields.

Composition of 4343/3003/7072 Clad Aluminum Sheet Strip

4343 Aluminum Alloy: This is an aluminum-silicon alloy, commonly used for welding materials and heat exchangers. Its high silicon content improves the flow and casting properties of aluminum.

Characteristics: It has good corrosion resistance and weldability, along with excellent thermal conductivity.

Applications: Typically used as the outer layer of composite materials to provide protection and enhance thermal conductivity.

3003 Aluminum Alloy: This is an aluminum-manganese alloy, often used for lightweight structures and body materials. Its corrosion resistance and good workability make it widely popular in many applications.

Characteristics: Moderate strength, good formability and weldability, and good corrosion resistance.

Applications: Serves as the intermediate layer to enhance the strength and toughness of the composite material.

7072 Aluminum Alloy: This is an aluminum-zinc alloy, usually used for structural components requiring high strength, such as aerospace and military applications.

Characteristics: High strength, good corrosion resistance, and good formability.

Applications: Typically used as the inner layer of composite materials to provide structural strength and rigidity.

Data Parameters of 4343/3003/7072 Clad Aluminum Sheet Strip

| Alloy | Temper | Thickness(mm) | Tolerance(mm) | Clad rate(%) |

| 4343/3003 | O | 1.2~3 | ±0.03 | 5~10 |

| 4343/3003/7072 | O | 1.2~8.3 | ±0.03 | 5~10 |

Characteristics of 4343/3003/7072 Clad Aluminum Sheet Strip

- 1. Strength-to-Weight Ratio: The 4343/3003/7072 clad aluminum sheet strip combines the advantages of different aluminum alloys, providing an excellent strength-to-weight ratio, making it suitable for high-strength applications that require lightweight materials.

- 2. Corrosion Resistance: Due to the use of different aluminum alloys, the 4343/3003/7072 clad aluminum sheet strip exhibits good corrosion resistance, making it suitable for use in harsh environments.

- 3. Good Machinability: The clad aluminum sheet strip can be processed through conventional machining, welding, stamping, and other methods, facilitating subsequent manufacturing and assembly.

- 4. Thermal Conductivity: The inclusion of the 4343 alloy enhances the thermal conductivity of the material, making it suitable for applications such as heat exchangers.

Chemical Composition of 4343/3003/7072 Clad Aluminum Sheet Strip

Core Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti | code |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | 0.1 | 0.05 | 0.03 | - |

Cladding Material

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Zr | Ti | code |

| 4343 | 6.8 - 8.2 | 0.8 | 0.25 | 0.1 | - | 0.20 | - | 0.05 | - |

| 7072 | 0.3 | 0.4 | 0.1 | 0.1 | 0.1 | 0.8-1.3 | - | 0.- |

Strength Of 4343/3003/7072 Clad Aluminum Sheet Strip

|

Alloy |

Temper | Yield Strength | Tensile Strength | Temsile Strength | Yield Strength |

|

4343/3003/7072/4343 |

H O | > / = 45 | 130 -160 | 155 | 60 |

Why Choose HC Aluminum for Brazed Aluminum Materials?

HC Aluminum offers a variety of brazed aluminum materials, allowing you to purchase 4343/3003/7072 brazed aluminum materials with confidence from our factory. We design and manufacture various brazed aluminum materials, such as 4343/3003/7072, 4343/3005/7072, 4343/3003, 4343/3003/4343, 4045/3003, and 4045/3003/7072, among others.

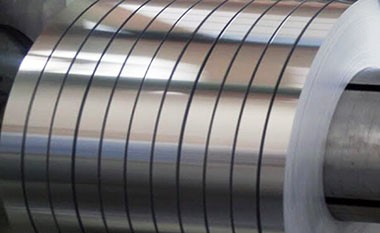

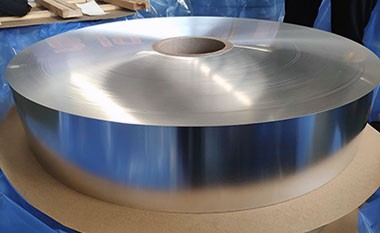

- 1. The surface of brazed aluminum materials is bright, free from corrosion and oxidation.

- 2. Straight and non-deformed.

- 3. Cut surfaces are neat and smooth, with no burrs.

- 4. High-frequency welding with precise specifications.

Applications of 4343/3003/7072 Clad Aluminum Sheet Strip

These materials can be used in various heat exchange structures, where the primary function is efficient heat transfer. Additionally, this fin foil is suitable for evaporators and condensers in most residential, automotive, and commercial air conditioning units, as well as humidifiers.

4343/3003/7072 Aluminum High Frequency Welded Tube for Radiator Condenser

This high-frequency welded aluminum tube is made from a combination of 4343, 3003, and 7072 alloys, used in radiator condensers where efficient heat transfer and structural integrity are crucial.

The 4343/3003/7072 Aluminum High Frequency Welded Tube is mainly used in automotive and industrial radiator condensers, where efficient coolant circulation is vital for engine cooling.

High-frequency welding ensures strong joints with minimal thermal distortion, and this alloy combination provides excellent heat transfer and corrosion resistance.

Alloy 4343/3003/7072 Aluminum Radiator Tube High Frequency Aircraft Welded

Used in aircraft radiators, where reducing weight and effective heat dissipation are critical for performance and safety. High-frequency welding provides clean, strong welds, minimizing the risk of failure under pressure.

The high-frequency welded tube made from alloys 4343, 3003, and 7072 is lightweight yet high in strength, contributing to improved fuel efficiency for aircraft.

4343/3003/mod3/7072 Aluminum Heat Transfer Plates High Strength For Radiator

These heat transfer plates are made from a mixture of alloys 4343, 3003 (mod3), and 7072, designed to optimize heat exchange in radiator systems. The modified 3003 alloy enhances specific performance for efficient heat transfer in automotive and industrial applications.

4343/3003/7072 Aluminium Extruded Profiles High Frequency Welding Auto Radiator Tube

These profiles are made from high-frequency welded aluminum extrusions, composed of alloys 4343, 3003, and 7072. They are designed specifically for automotive radiator applications, balancing strength, weight, and thermal conductivity.

The extruded profiles offer design flexibility, allowing customization based on specific cooling requirements. High-frequency welding ensures reliable joints, enhancing the overall efficiency and lifespan of the radiator system.