4343/3003 Clad Aluminum Sheet Strip

The 4343/3003 clad aluminum sheet strip is a composite aluminum sheet made from 4343 and 3003 aluminum alloys through a specific process. This composite material is typically used in applications requiring good thermal conductivity and excellent formability.

The 4343/3003 clad aluminum sheet strip is widely used in the automotive industry, air conditioning equipment, heat exchangers, and other applications that require a combination of strength, corrosion resistance, and heat dissipation performance.

The 4343/3003 clad aluminum sheet is a material with excellent properties, suitable for various industrial applications, especially in scenarios requiring high strength and lightweight characteristics.

Composition of 4343/3003 Clad Aluminum Sheet Strip

4343 Aluminum Alloy

The 4343 aluminum alloy is primarily used for the surface layer, offering excellent corrosion resistance and weldability, commonly utilized in the outer layer of heat exchangers.

The 4343 aluminum alloy is typically used for welding aluminum materials and in heat exchangers. This alloy has good corrosion resistance and excellent welding properties.

3003 Aluminum Alloy

The 3003 aluminum alloy serves as the base material, providing good formability and machinability, suitable for various forming processes.

The 3003 aluminum alloy is an aluminum-manganese alloy known for its good formability, weldability, and corrosion resistance, commonly used in the manufacturing of various food and chemical processing equipment.

Advantages of 4343/3003 Clad Aluminum Sheet Strip

- Strong corrosion resistance: The 3003 aluminum sheet, as an aluminum-manganese alloy, exhibits excellent corrosion resistance, making it suitable for use in various environments and effectively extending the product's lifespan.

- High strength: The 3003 aluminum alloy possesses relatively high strength, and after brazing and composite treatment, its load-bearing capacity is significantly enhanced, making it suitable for applications subject to high pressure and loads.

- Excellent heat dissipation capability: The composite of the 4343 and 3003 aluminum sheets significantly improves heat dissipation performance, making it ideal for devices and components that require efficient heat dissipation, such as heat exchangers and radiators.

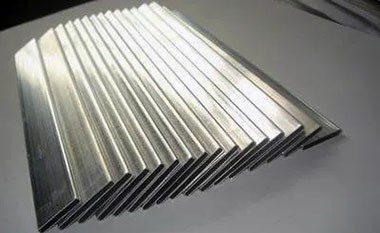

- Outstanding stamping and stretching performance: The 3003-O aluminum sheet is soft and has good plasticity, making it easy to perform stamping and stretching operations, meeting various conventional processing needs and suitable for manufacturing complex-shaped components.

- Good stability: The composite aluminum sheet has excellent performance stability, high elongation, and is easy to stamp and weld, ensuring that it maintains excellent performance during processing and use.

- Lightweight material: The low density of aluminum alloys makes the 4343/3003 clad aluminum sheet strip an ideal lightweight material, widely used in automotive and aerospace fields, helping to improve energy efficiency and reduce weight.

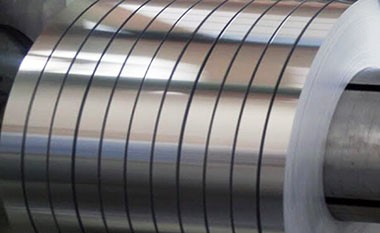

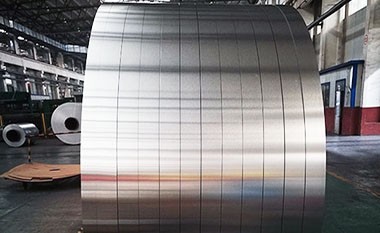

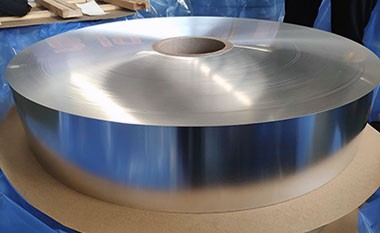

Specification of 3003 4343 brazing aluminum plate

| Alloy | 3003 | 3003 | 3003mod |

| Brazing clad for CAB | 4045 | 4343 | 4343 |

| Temper | O, H14 | ||

| Regular Thickness(mm) | 0.6–3.0 | ||

| Width(mm) | 12-1240 | ||

| Length(mm) | C | ||

| Clad Rate | 4-18% per side, or customer requested | ||

| ID | 75 150 200 300 500 | ||

| OD | Max 1800 | ||

| Coil Weight(kg) | Max 8000 | ||

| Packing | Export standard package | ||

| Normal Alloys Plates | 4045/3003, 4343/3003, 4045/3003/4045, 4343/3003/4343, 4343/3003/7072 and etc. | ||

Data parameters and performance of 4343/3003 Clad Aluminum Sheet Strip

| Alloy | Temper | Thickness(mm) | Tolerance(mm) | Clad rate(%) |

| 3003 | H14 | 0.06~0.1 | ±0.005 | None |

| 3003 Mechanical property | ||

| Tensile Strength(MPa) | Yield Strength(MPa) | ElongationMin.(%) |

| 150~200 | ≥120 | 1 |

| Alloy | Temper | Thickness(mm) | Tolerance(mm) | Clad rate(%) |

| 4343/3003 | O | 1.2~8.3 | ±0.03 | 5~10 |

| 4343/3003 Mechanical property | ||

| Tensile Strength(MPa) | Yield Strength(MPa) | Elongation Min.(%) |

| 100~150 | ≥45 | 25 |

| 100~150 | ≥45 | 25 |

Applications of 4343/3003 Clad Aluminum Sheet Strip

4343/3003 Brazing Cladding Aluminum Heat Exchanger

The 4343/3003 clad aluminum sheet strip is used in heat exchangers for automotive, HVAC, and industrial applications, where efficient heat transfer is critical.

The 4343/3003 clad aluminum layer is designed to melt and flow during the brazing process, effectively bonding the layers together and ensuring high thermal conductivity.

The combination of the two alloys in 4343/3003 clad aluminum optimizes heat transfer capability, making it highly effective for heat exchangers. The 3003 alloy is easy to manufacture, while the 4343 ensures strong joints during the brazing process.

4343/3003 Brazing Aluminum Plate for Electric Vehicle Battery Cooling Plates

The 4343/3003 brazing aluminum plate can be integrated into larger thermal management systems within electric vehicles, thereby enhancing overall energy efficiency.

The design of the 4343/3003 clad aluminum allows for efficient cooling, which is essential for maintaining battery performance and lifespan. The brazing performance of 4343 enables an efficient manufacturing process, allowing for the precise production of complex designs.