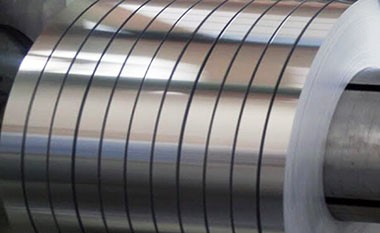

4545/3003/4545 Aluminum Clad Brazing Sheet Strip

The 4545/3003/4545 Aluminum Clad Brazing Sheet Strip consists of three layers of aluminum alloy, with the outer layers made of 4545 aluminum alloy and the middle layer made of 3003 aluminum alloy. This design provides the material with good performance in terms of strength, toughness, and corrosion resistance.

What is aluminum clad sheet?

Aluminum clad sheet, also known as aluminum composite panel or aluminum composite sheet, is a type of material that consists of two thin layers of aluminum enclosing a non-aluminum core. This composite structure combines the desirable properties of aluminum with the benefits of the core material, which can vary in composition.

Specifications of 4545/3003/4545 Aluminum Clad Brazing Sheet Strip

HC Aluminum produces brazing aluminum sheets with a full range of specifications, and coverage is based on customer requirements. The brazing sheets produced are mainly used for the composite of radiators, tanks, fins, evaporator baffles, main pieces, protective plates, etc.

| Grade | 4045/3003/4045 |

| Core Alloy | 3003 |

| Cladding Alloy | 4045 |

| Status | H14 |

| Composite layer (%) | 8~12 |

| Thickness (mm) | 0.10~0.15 |

| Tolerance (mm) | ±0.005 |

| Tensile strength σb (MPa) | 160~200 |

| Elongation δ (%) | ≥1 |

| Yield strength σ0.2 (MPa) | ≥125 |

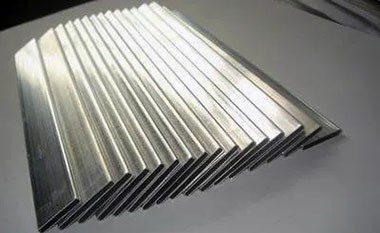

| Main use | fins, radiator belts |

Material Composition of 4545/3003/4545 Aluminum Clad Brazing Sheet Strip

Outer Layer (4545 Aluminum Alloy)

Material Properties:

- Chemical Composition: The 4545 aluminum alloy mainly consists of aluminum, silicon, magnesium, and other elements. The design of its alloy composition ensures excellent performance in strength and corrosion resistance.

- Corrosion Resistance: The outer layer aluminum alloy undergoes an oxidation treatment, forming a dense aluminum oxide layer on its surface, which effectively enhances its corrosion resistance, making it suitable for use in humid or corrosive environments.

Mechanical Properties:

- Strength: The 4545 aluminum alloy has high tensile strength and yield strength, making it suitable for bearing significant external forces.

- Toughness: While ensuring strength, this alloy also possesses good toughness, allowing it to withstand impact and fatigue.

Middle Layer (3003 Aluminum Alloy)

Material Properties:

- Chemical Composition: The 3003 aluminum alloy contains aluminum and manganese. The addition of manganese enhances the alloy’s corrosion resistance and weldability.

- Formability: The excellent formability of the 3003 aluminum alloy makes it suitable for processing complex shapes, allowing for forming through stamping, bending, and other processes.

Toughness:

Enhancement: The toughness of the middle layer 3003 aluminum alloy improves the overall performance of the composite material, enabling it to better dissipate stress when subjected to impact or deformation, thereby reducing the risk of cracking.

Brazing Process

Process Flow:

- Preparation Stage: Before brazing, the contact surfaces of the three layers of aluminum alloy must be cleaned to remove surface oil and oxidation layers, ensuring good bonding.

- Heating Stage: The material is heated to the brazing temperature, typically between 450°C and 600°C. This temperature allows the brazing filler to melt and penetrate the contact surfaces of the aluminum alloy.

- Welding Stage: While heating, appropriate pressure is applied to ensure the brazing filler is evenly distributed and fully bonded with the aluminum alloy.

Bonding Strength:

- Stability: The brazing process ensures a strong bond between the three layers of material, forming a stable composite structure capable of effectively withstanding various mechanical loads.

- Seamless Connection: The advantage of brazing lies in achieving a seamless connection, reducing stress concentration and potential weak points, thereby enhancing the overall reliability of the structure.

Characteristics of 4545/3003/4545 Aluminum Clad Brazing Sheet Strip

1. High Strength

The 4545/3003/4545 aluminum composite brazing sheet strip features a three-layer aluminum alloy composite structure, allowing the material to provide excellent strength while maintaining a lightweight profile. The 4545 aluminum alloy layer in the composite structure offers high tensile and yield strength, making it suitable for bearing significant mechanical loads. The middle layer, made of 3003 aluminum alloy, enhances toughness, enabling the overall material to effectively dissipate stress during impacts or vibrations, reducing the risk of cracking.

2. Excellent Thermal Conductivity

Aluminum alloys possess good thermal conductivity, and the combination of 4545 and 3003 aluminum alloys results in outstanding performance in heat dissipation applications. The high thermal conductivity of aluminum effectively transfers heat from high-temperature areas to low-temperature areas, thereby improving the cooling efficiency of the system.

3. Corrosion Resistance

The surface of the 4545 aluminum alloy undergoes oxidation treatment, forming a dense aluminum oxide layer that significantly enhances its corrosion resistance. Additionally, the middle layer of 3003 aluminum alloy also exhibits good corrosion resistance, making the entire composite material perform excellently in humid or chemically corrosive environments.

Applications of 4545/3003/4545 Aluminum Composite Brazing Sheet Strip

1. Air Conditioning and Refrigeration Equipment

Heat Exchangers: The 4545/3003/4545 aluminum composite brazing sheet strip is widely used in the manufacturing of heat exchangers due to its excellent thermal conductivity and corrosion resistance. Heat exchangers play a crucial role in air conditioning and refrigeration systems, efficiently facilitating heat exchange and ensuring the equipment operates efficiently under various working conditions.

Condensers and Evaporators: In condensers, the high strength and good heat dissipation performance of aluminum composite materials effectively lower the temperature of the coolant, thereby enhancing system efficiency. In evaporators, the lightweight characteristics of aluminum alloys make the equipment easier to install and maintain, while also improving the system's responsiveness and efficiency. These features make the 4545/3003/4545 aluminum composite brazing sheet strip an ideal choice for the refrigeration industry.

2. Automotive Industry

Cooling Systems: In automotive cooling systems, the 4545/3003/4545 aluminum composite brazing sheet strip is used in the manufacture of radiators and coolant pipelines. Its excellent thermal conductivity and lightweight characteristics effectively enhance engine cooling efficiency, helping maintain optimal operating temperatures, thereby improving overall vehicle performance and fuel economy.

Radiators: The corrosion resistance of aluminum composite materials also ensures that automotive radiators perform well in various environmental conditions (such as humidity, salt spray, etc.), extending the lifespan of the radiators.

3. Electronic Devices

Heat Dissipation Solutions: The 4545/3003/4545 aluminum composite brazing sheet strip is widely used in the manufacture of heat sinks and radiators in electronic devices.