6061 T4 T6 Electrical Aluminum Busbar

The 6061 aluminum busbar is a special type of electrical busbar made from 6061 aluminum alloy. Due to its excellent mechanical properties and corrosion resistance, it is widely used in electrical and structural applications.

6061 aluminum busbars are widely used due to their excellent combination of strength, corrosion resistance, and workability in electrical systems.

HC Aluminum 6101 EC grade aluminum busbars comply with IEC 60105, ISO 209-1, 2, DIN EN 755-2, and DIN EN 755-5 standards. The 6101 aluminum busbar features a smooth, burr-free surface, excellent electrical conductivity, high strength, good corrosion resistance, and a lightweight design.

HC Aluminum suppliers offer 6061 T6, but we can also special order any size of any alloy and customize cut sizes according to your requirements.

6061 Aluminum Busbar Material Properties

- Composition: 6061 aluminum alloy is primarily composed of aluminum, with magnesium (1.0-1.5%) and silicon (0.4-0.8%) as the main alloying elements, which provide excellent strength and corrosion resistance.

- Strength: It offers a good balance between strength and formability.

- Corrosion Resistance: Excellent resistance to atmospheric corrosion, making it suitable for both indoor and outdoor applications.

- Weldability and Machinability: 6061 aluminum is known for its good weldability, allowing easy fabrication and welding without significantly reducing strength. It also has good machinability, enabling precise cutting and shaping to meet the requirements of busbar applications.

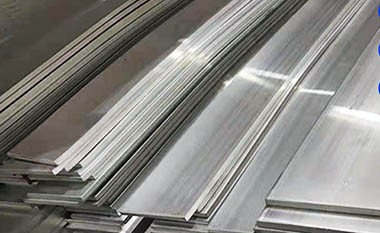

6061 T4 T6 Electrical Aluminum Busbar Specifications

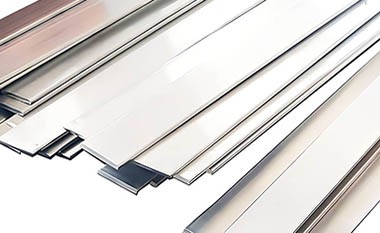

- Shape and Size: The busbars can be produced in various shapes, including flat, round, and rectangular profiles. Sizes can vary greatly based on specific application requirements.

- Surface Treatment: The busbars can undergo various surface treatments, such as anodizing, to enhance corrosion resistance and electrical conductivity. Anodizing can also improve aesthetics.

| Feature | 6061 Flat Busbar | 6061 Round Corner Busbar |

| Shape | Rectangular | Rectangular with rounded corners |

| Handling | Sharp corners may pose risks | Safer handling due to rounded edges |

| Airflow | Minimal airflow improvement | Improved airflow around corners |

| Manufacturing | Typically easier to manufacture | Requires more precise machining |

| Applications | General power distribution | Ideal for applications prioritizing safety and aesthetics |

Properties of HC aluminum 6061 flat busbar

| Alloy-temper | 6061-T6 | 6061-T651 | 6061-T6511 |

| Tensile Strength | 270-310 MPa | 270-320 MPa | 270-290 MPa |

| Shear Strength | 210MPa | 210 MPa | 170MPa |

| Elastic Modulus | 69GPa | 69GPa | 69GPa |

| Brinell Hardness | 93 | 93 | - |

| Elongation at Break | 10% | 11% | 9% |

| Thermal conductivity (20°C) | 3.9 | ||

| Electrical conductivity (20°C) | 42-43 | ||

| Electrical resistivity (dc) (20°C) | 19.39 18.94 | ||

| Temperature coefficient of electrical resistance (20°C) | 0.00284 0.00277 | ||

6061 Aluminum Busbar Product Sizes

6101 Aluminum Flat Bus Bar

| Thickness A (in) | Width B (in) | Estimated Weight per lb/ft |

| 1/8 | 0.375 | 0.055 |

| 1/8 | 0.500 | 0.074 |

| 1/8 | 0.625 | 0.090 |

| 1/8 | 0.750 | 0.110 |

| 1/8 | 0.875 | 0.127 |

| 1/8 | 1.000 | 0.149 |

| 1/8 | 1.250 | 0.184 |

| 1/8 | 2.000 | 0.299 |

| 1/8 | 2.500 | 0.371 |

| 1/8 | 4.000 | 0.599 |

| 3/16 | 0.375 | 0.084 |

| 3/16 | 0.500 | 0.112 |

| 3/16 | 0.625 | 0.140 |

| 3/16 | 0.750 | 0.168 |

| 3/16 | 0.875 | 0.187 |

| 3/16 | 1.000 | 0.222 |

| 3/16 | 2.000 | 0.442 |

| 1/4 | 0.500 | 0.149 |

| 1/4 | 0.750 | 0.209 |

| 1/4 | 1.000 | 0.284 |

| 1/4 | 1.250 | 0.359 |

| 1/4 | 1.500 | 0.434 |

| 1/4 | 2.000 | 0.584 |

| 1/4 | 2.500 | 0.734 |

| 1/4 | 3.000 | 0.884 |

| 1/4 | 3.250 | 0.959 |

| 1/4 | 4.000 | 1.184 |

| 1/4 | 4.500 | 1.334 |

| 1/4 | 5.000 | 1.484 |

| 1/4 | 6.000 | 1.784 |

| 1/4 | 7.000 | 2.084 |

| 1/4 | 8.000 | 2.384 |

| 3/8 | 0.625 | 0.277 |

| 3/8 | 1.25 | 0.527 |

| 3/8 | 2 | 0.864 |

| 3/8 | 2.5 | 1.120 |

| 3/8 | 3 | 1.134 |

| 3/8 | 4 | 1.764 |

| 3/8 | 5 | 2.214 |

| 3/8 | 6 | 2.664 |

| 3/8 | 8 | 3.596 |

| 1/2 | 0.75 | 0.385 |

| 1/2 | 1.5 | 0.896 |

| 1/2 | 2 | 1.196 |

| 1/2 | 3 | 1.796 |

| 1/2 | 4 | 2.396 |

| 1/2 | 5 | 2.996 |

| 1/2 | 6 | 3.596 |

| 1/2 | 8 | 4.796 |

| 1/2 | 10 | 5.996 |

| 3/4 | 1 | 0.884 |

| 3/4 | 4 | 3.455 |

| 3/4 | 5 | 4.495 |

| 1 | 1.25 | 1.498 |

| 1 | 8 | 9.535 |

| 1 | 10 | 11.996 |

| 1 | 12 | 14.364 |

Rounded Corners 6061 Aluminum Busbar

| Thickness A (in) | Width B (in) | Radius R (in) | Estimated Weight per lb/ft |

| 1/8 | 0.375 | 0.031 | 0.055 |

| 1/8 | 0.5 | 0.016 | 0.074 |

| 1/8 | 0.5 | 0.031 | 0.074 |

| 1/8 | 0.625 | 0.062 | 0.09 |

| 1/8 | 0.75 | 0.031 | 0.11 |

| 1/8 | 0.875 | 0.062 | 0.127 |

| 1/8 | 1 | 0.031 | 0.149 |

| 1/8 | 1.25 | 0.062 | 0.184 |

| 1/8 | 2 | 0.031 | 0.299 |

| 1/8 | 2.5 | 0.031 | 0.371 |

| 1/8 | 4 | 0.031 | 0.599 |

| 3/16 | 0.375 | 0.031 | 0.084 |

| 3/16 | 0.5 | 0.031 | 0.112 |

| 3/16 | 0.625 | 0.031 | 0.14 |

| 3/16 | 0.75 | 0.016 | 0.169 |

| 3/16 | 0.75 | 0.031 | 0.168 |

| 3/16 | 0.875 | 0.094 | 0.187 |

| 3/16 | 1 | 0.062 | 0.222 |

| 3/16 | 2 | 0.094 | 0.442 |

| 1/4 | 0.5 | 0.031 | 0.149 |

| 1/4 | 0.75 | 0.125 | 0.209 |

| 1/4 | 1 | 0.125 | 0.284 |

| 1/4 | 1.25 | 0.125 | 0.359 |

| 1/4 | 1.5 | 0.125 | 0.434 |

| 1/4 | 2 | 0.125 | 0.584 |

| 1/4 | 2.5 | 0.125 | 0.734 |

| 1/4 | 3 | 0.125 | 0.884 |

| 1/4 | 3.25 | 0.125 | 0.959 |

| 1/4 | 4 | 0.125 | 1.184 |

| 1/4 | 4.5 | 0.125 | 1.334 |

| 1/4 | 5 | 0.125 | 1.484 |

| 1/4 | 6 | 0.125 | 1.784 |

| 1/4 | 7 | 0.125 | 2.084 |

| 1/4 | 8 | 0.125 | 2.384 |

| 3/8 | 0.625 | 0.062 | 0.277 |

| 3/8 | 1.25 | 0.188 | 0.527 |

| 3/8 | 2 | 0.062 | 0.895 |

| 3/8 | 2 | 0.187 | 0.864 |

| 3/8 | 2.5 | 0.062 | 1.12 |

| 3/8 | 3 | 0.187 | 1.314 |

| 3/8 | 5 | 0.187 | 2.214 |

| 3/8 | 4 | 0.187 | 1.764 |

| 3/8 | 6 | 0.187 | 2.664 |

| 3/8 | 8 | 0.062 | 3.596 |

| 1/2 | 0.75 | 0.250 | 0.385 |

| 1/2 | 1.5 | 0.062 | 0.896 |

| 1/2 | 2 | 0.062 | 1.196 |

| 1/2 | 3 | 0.062 | 1.796 |

| 1/2 | 4 | 0.062 | 2.396 |

| 1/2 | 5 | 0.062 | 2.996 |

| 1/2 | 6 | 0.062 | 3.596 |

| 1/2 | 8 | 0.062 | 4.796 |

| 1/2 | 10 | 0.062 | 5.996 |

| 3/4 | 1 | 0.125 | 0.884 |

| 3/4 | 4 | 0.375 | 3.455 |

| 3/4 | 5 | 0.062 | 4.495 |

| 1/1 | 1.25 | 0.031 | 1.498 |

| 1/1 | 8 | 0.25 | 9.535 |

| 1/1 | 10 | 0.062 | 11.996 |

| 1/1 | 12 | 0.188 | 14.364 |

Chemical composition of HC Aluminum 6061 conductive aluminum busbar

| Element | Percentage (%) |

| Aluminum (Al) | Balance (min. 95.0%) |

| Silicon (Si) | 0.4 - 0.8 |

| Iron (Fe) | 0.0 - 0.7 |

| Copper (Cu) | 0.15 - 0.4 |

| Manganese (Mn) | 0.15 - 0.8 |

| Magnesium (Mg) | 0.8 - 1.2 |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | 0.0 - 0.25 |

| Titanium (Ti) | 0.0 - 0.15 |

| Others | Each 0.05 max, Total 0.15 max |

6061 Aluminum Busbar Physicaproperties (approximate values, 20℃)

| Density [kg/m3] | Melting range [℃] | Electrical Conductivity [MS/m] | Therma Conductivity [W/m.K] | Co-efficient of Thermaexpansion 10-6/k | Modulus of elasticity [GPa] |

| 2700 | 585-640 | 22-30 | 170-200 | 23 | ≈70 |

Applications of 6061 Aluminum Busbar

| Application Area | Specific Use Description |

| Power Distribution | 6061 Aluminum Busbars are used in substations, switchgear, and distribution panels to efficiently connect different electrical components. |

| Renewable Energy | Used in solar power systems to connect solar panels to inverters and batteries for power transmission. |

| Used in wind turbines to deliver the generated electricity to the grid. | |

| Transportation | Used in electric vehicle distribution systems to connect batteries, drive motors, and other electrical components. |

| Used in railway systems to ensure power transmission from the supply source to trains and related infrastructure. | |

| Power Transmission | 6061 Aluminum Busbars are used in high-voltage power transmission lines to reduce energy loss and improve overall efficiency. |

Advantages and Limitations of 6061 Aluminum Busbar

| Advantages | Limitations |

| Lightweight | Lower conductivity |

| Compared to copper busbars, aluminum busbars are significantly lighter, making them easier to handle and install. | While aluminum has good conductivity, it is lower than that of copper, which may require a larger cross-section to meet the same current-carrying capacity. |

| Cost-effective | Oxidation issues |

| Aluminum is generally cheaper than copper, making 6061 aluminum busbars an economical choice for many applications. | Although aluminum has good corrosion resistance, an improperly managed oxide layer (such as a lack of surface treatment or not using conductive grease) can affect electrical connections. |

| Good thermal conductivity | |

| Aluminum has good thermal conductivity, which helps with heat dissipation in high-current applications. |

6061 Aluminum Busbar Processing and Fabrication

- Extrusion: 6061 aluminum can be easily extruded into various profiles, making it suitable for manufacturing busbars in different shapes, including flat, round, or custom cross-sections.

- Finishing: The busbars can undergo anodizing or other surface treatments to improve their corrosion resistance and appearance, especially for outdoor or exposed environments.

- Manufacturing Methods: Common fabrication techniques for 6061 aluminum busbars include cutting, bending, punching, and welding to create the desired design.

6061 aluminum busbars are a reliable and efficient choice for electrical systems, offering a balance between cost, performance, and durability. Their applications span across various industries, including power distribution, industrial manufacturing, transportation, and renewable energy.