6063 T4 T6 Electrical Aluminum Busbar

6063 aluminum busbars are conductive components made from 6063 aluminum alloy, which primarily consists of aluminum, magnesium, and silicon. This alloy is renowned for its excellent machinability, weldability, and corrosion resistance, making it a popular choice for various electrical applications.

While 6063 aluminum busbars offer numerous advantages, they may not be suitable for applications that require the highest strength or conductivity. In such cases, alloys such as 6061 or 6101 aluminum are preferred.

6063 aluminum busbars are versatile components that combine good conductivity, mechanical properties, and corrosion resistance, making them suitable for a wide range of electrical and construction applications.

6063 aluminum busbars are electrical conductors made from 6063 aluminum alloy. Due to their lightweight and ability to effectively handle large currents, they are commonly used in power distribution systems.

The main elements in the chemical composition of 6063 aluminum busbars are magnesium and silicon. They exhibit excellent processing performance, welding capability, extrusion properties, and electroplating quality, along with good corrosion resistance, toughness, and ease of polishing. They also have excellent coating and anodizing effects, making them a typical extrusion alloy.

HC Aluminum 6063 EC grade busbars meet standards such as ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, and EN 573-3. The surface of 6063 aluminum busbars is smooth and burr-free, offering excellent conductivity, high strength, good corrosion resistance, and a lightweight design.

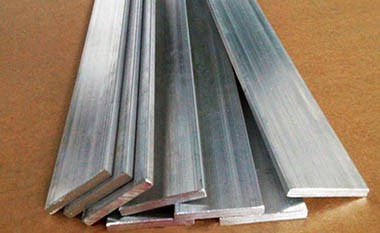

6063 Aluminum Busbar Characteristics

- Electrical Conductivity: 6063 aluminum has high conductivity, suitable for carrying large electrical loads in busbars.

- Corrosion Resistance: This alloy exhibits outstanding corrosion resistance, which is crucial for extending its lifespan in various environmental conditions.

- Lightweight: 6063 aluminum busbars are lighter than copper, reducing the overall weight of electrical equipment, making them easier to handle and install.

- Extrudability: 6063 is known for its good extrudability, allowing manufacturers to produce busbars in various shapes and sizes to meet specific design requirements.

- Thermal Conductivity: It also has good thermal conductivity, aiding in heat dissipation during operation.

6063 Aluminum Busbar Parameter Data

| Property | Description |

| Temper Types | T5: Solution heat-treated and artificially aged. T6: Solution heat-treated and artificially aged with higher strength. |

| Extrusion | Easily extruded into various shapes, including rectangular and round busbars. The extrusion process can be tailored to meet specific electrical and mechanical requirements. |

| Machinability | Good machinability allows for cutting, drilling, and milling, making it easy to fabricate into custom busbar designs. |

| Surface Treatment | Anodizing, electroplating, spraying, etc. Usually aluminum plating includes: silver, tin, nickel |

| Insulation treatment | Insulation coating: powder coating, epoxy resin coating or insulation paint coating, etc. Insulating sleeve: polyvinyl chloride (PVC), heat shrink tubing, or silicone rubber, etc. |

6063 Aluminum Busbar Standards and Certifications

- ASTM B317: Specifies extruded aluminum busbars, including 6063.

- IEC 60439: Governs low-voltage switchgear assemblies.

- NEC (NFPA 70): Guidelines for safe electrical installations.

Typical Sizes of 6063 Aluminum Busbars

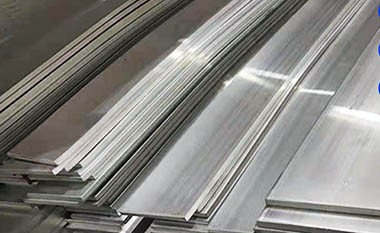

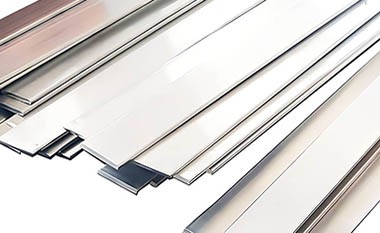

Common profiles: flat bars (e.g., 100mm x 10mm) or custom extruded profiles.

Current capacity: varies with cross-section (e.g., 100mm x 10mm can carry 1000A at 50°C rise).

HC Aluminum supplies conductive aluminum busbar products made from 1050, 1060, 1070, 1100, 1350, 6060, 6082, 6101, etc., strictly controlling the quality of the aluminum busbar, with competitive prices.

6063 aluminum busbars provide a cost-effective, lightweight solution for modern electrical systems, especially when extrusion complexity and corrosion resistance are prioritized. While they require careful design to address conductivity and thermal expansion issues, their versatility and sustainability make them the preferred choice in various applications.

HC Aluminum hot selling 6063 flat busbar products

| Type | Description | Applications | Advantages |

| 6063 Extruded Aluminum Flat Busbar | 6063 Aluminum Busbar in flat form is designed for efficient power distribution with excellent conductivity and corrosion resistance, making it ideal for electrical applications. | Switchgear, electrical panels, busway systems. | High conductivity, easy to mount and connect. |

| 6063 Round Corner Aluminum Busbar | 6063 Aluminum Busbar with round corners provides a smooth, durable connection in electrical systems, offering improved safety and ease of installation. | Public infrastructure, commercial buildings. | Enhanced safety, better thermal performance. |

| 6063 T4 Electrical Aluminum Busbar | 6063 Aluminum Busbar in T4 temper is optimized for electrical conductivity and moderate strength, making it suitable for a variety of power distribution applications. | Applications with bending/forming needs. | Good balance of strength and workability. |

| 6063 T6 Electrical Aluminum Busbar | 6063 Aluminum Busbar in T6 temper offers high strength and excellent corrosion resistance, ensuring reliable performance in demanding electrical environments. | Heavy-duty electrical systems, high-current applications. | Enhanced strength, excellent conductivity and corrosion resistance. |

Properties of HC Aluminum 6063 electrical aluminum busbar

| Mechanical and electrical property | ||||

| Temper | 6063-T4 | 6063-T5 | 6063-T6 | 6063-T66 |

| Yield Stress Rp0.2(Mpa) | 65 | 110-130 | 160-170 | 10-25 |

| Tensile strength Rm (Mpa) | 130 | 160-175 | 195-215 | 225-245 |

| Elongation A [%] | 14 | 7-8 | 8 | 8 |

| Elongation A50mm [%] | 12 | 5-6 | 6 | 6 |

| Electrical conductivity [MS/m] | 28-34 | |||

| Electrical resistivity | 15.37 | |||

Chemical composition of HC Aluminum 6063 conductive aluminum busbar

| Element | Symbol | Percentage (%) |

| Aluminum | Al | Balance (97.0 - 99.5) |

| Silicon | Si | 0.2 - 0.6 |

| Iron | Fe | 0.1 max |

| Copper | Cu | 0.1 max |

| Manganese | Mn | 0.1 max |

| Magnesium | Mg | 0.45 - 0.9 |

| Chromium | Cr | 0.05 max |

| Zinc | Zn | 0.1 max |

| Titanium | Ti | 0.1 max |

| Other Elements | - | 0.05 max each, 0.15 max total |

Advantages and Limitations of 6063 Aluminum Busbar

| Advantages | Description |

| Corrosion Resistance | 6063 aluminum naturally forms a protective oxide layer, enhancing its durability in various environments. |

| Lightweight | 6063 aluminum is lighter than copper, helping to reduce the overall weight of the electrical system. |

| Cost-Effectiveness | 6063 aluminum is generally cheaper than copper while providing sufficient conductivity for many applications. |

Limitations

Lower Conductivity: Compared to copper busbars, 6063 aluminum has lower conductivity, which may be a consideration in high-power applications.

6063 Aluminum Busbar Applications

| Application Area | Detailed Description |

| Power Distribution | 6063 aluminum busbars are used in distribution boards, switchgear, and substations, enabling efficient power distribution and ensuring the stability and reliability of power systems. |

| Industrial Uses | In various industrial electrical systems, 6063 aluminum busbars are favored for their lightweight and good conductivity, suitable for environments requiring efficient power transmission. |

| Commercial Buildings | 6063 aluminum busbars are commonly used in the power distribution wire systems of commercial buildings, helping to reduce the overall weight of the building while meeting power distribution needs. |

| Busway Systems | In busway systems, 6063 aluminum busbars are used to connect different electrical components and distribute power, providing flexible power distribution solutions that adapt to varying layout requirements. |

| Renewable Energy | 6063 aluminum busbars are widely used in solar inverters and wind turbine systems, supporting effective electrical connections and energy transmission, contributing to the utilization and development of renewable energy. |

6063 Aluminum Busbar Manufacturing Process

Extrusion: 6063 aluminum alloy is heated and extruded into the desired shape (flat, round, or custom profiles).

Surface Treatment: Busbars can undergo surface treatments such as anodizing or painting to enhance corrosion resistance and aesthetics.

Cutting and Processing: The extruded busbars are cut to specific lengths and can be processed to accommodate connectors and mounting hardware.