6101 T6 T61 T64 Electrical Aluminum Busbar

6101 Aluminum alloy is a heat-treatable wrought alloy, known for its excellent electrical conductivity and moderate strength, making it particularly suitable for electrical applications such as busbars.

- Chemical Composition: 6101 alloy is primarily composed of aluminum, including magnesium (0.35–0.8%) and silicon (0.3–0.7%), which enhance its mechanical strength without significantly compromising electrical conductivity.

- Electrical Conductivity: Approximately 59% of the International Annealed Copper Standard (IACS), which is lower than pure copper, but sufficient to meet the requirements of many electrical applications.

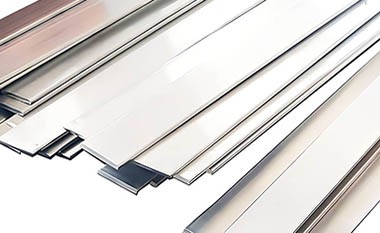

6101 aluminum busbars are available in various specifications, including different cross-sectional shapes (such as rectangular, round, etc.) and sizes, to meet specific current-carrying capacities and installation requirements.

6101 electrical aluminum busbars are an efficient, economical, and practical solution suitable for a wide range of electrical applications.

6101 aluminum busbars are made from aluminum alloy, typically containing a certain proportion of magnesium and silicon, providing excellent electrical conductivity and mechanical strength. Compared to pure aluminum, aluminum alloys offer significant advantages in strength and corrosion resistance.

HC Aluminum 6101 EC grade aluminum busbars comply with IEC 60105, ISO 209-1, 2, DIN EN 755-2, and DIN EN 755-5 standards. The 6101 aluminum busbars have a smooth surface with no burrs, exceptional conductivity, high strength, good corrosion resistance, and a lightweight design.

6101 Aluminum Busbar Specifications

The specifications of 6101 aluminum busbars are diverse, with common cross-sectional shapes including rectangular, round, and flat. The cross-sectional dimensions and lengths can be customized based on specific application requirements.

| Dimension Name | Specification |

| Material | Aluminum |

| Shape | Bar-Rectangle |

| Alloy | 6101 |

| Temper | T61 |

| Production Method | Extruded |

| Shape Type | Full Round Edge |

6101 Aluminum Busbar Characteristics

- Excellent conductivity: 6101 aluminum alloy has good electrical conductivity, approximately 61% IACS (International Annealed Copper Standard), making it highly efficient for electrical applications.

- Corrosion resistance: The oxide layer that naturally forms on 6101 alloy in the air provides excellent corrosion resistance, making it suitable for various environments.

- Mechanical strength: Although aluminum's strength is relatively low, the mechanical strength of 6101 alloy, after alloying and heat treatment, meets the structural requirements for electrical busbars.

- Good machinability: 6101 aluminum alloy is easy to extrude, bend, and weld, making it suitable for producing various shapes of electrical busbars.

- Lightweight: The low density of aluminum makes 6101 busbars lighter than copper busbars, helping to reduce installation costs and the load on supporting structures.

Chemical composition of HC Aluminum 6106 conductive aluminum busbar

| Element | Composition (%) |

| Aluminum (Al) | Balance |

| Copper (Cu) | 1.0 - 1.5 |

| Iron (Fe) | 0.5 max |

| Silicon (Si) | 0.5 max |

| Manganese (Mn) | 0.1 - 0.5 |

| Magnesium (Mg) | 0.15 max |

| Zinc (Zn) | 0.1 max |

| Titanium (Ti) | 0.1 max |

| Other Elements | 0.05 each, 0.15 total max |

Properties of HC Aluminum 6101 electrical aluminum busbar

| emper | Yield Strength Rp0.2(Mpa) | Ultimate tensile strength Rm(Mpa) | Elongation | Conductivity %IACS |

| 6101-T6 | ≥172 | ≥200 | 15 | - |

| 6101-T61 | ≥55 | ≥103 | - | ≥59% |

| 6101-T63 | ≥150 | ≥185 | - | ≥56 |

| 6101-T64 | ≥55 | ≥105 | - | ≥59.5 |

| 6101-T65 | - | - | - | ≥58% |

6101 Aluminum Busbar Mechanical Properties

| Mechanical Properties | |

| Property | Value |

| Ultimate Tensile Strength KSI | 18 |

| Density g/cm^3 | 3 |

| Brinell Hardness 500 kg load | 71 |

| Yield Tensile Strength KSI | 11 |

| Rockwell Hardness B Scale | 34 |

| Elongation % in 2 in. | 10 |

| Melting Point °F | 1150 - 1210 |

| Electrical Conductivity % IACS | 59 |

6101 aluminum and copper current carrying capacity comparison table

| Ampacity Conversion Chart | Copper C110 | 30° C Rise | 50° C Rise | 65° C Rise | Aluminum 6101 | 30° C Rise | 50° C Rise | 65° C Rise | ||||

| Flat Bar Size in Inches | Sq. In | Circ Mils Thousands | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp* | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp** | ||||

| 1/16 x 1/2 | 0.0312 | 39.7 | 0.121 | 264 | 103 | 136 | 157 | 0.037 | 494 | 58 | 76 | 88 |

| 1/16 x 3/4 | 0.0469 | 59.7 | 0.181 | 175 | 145 | 193 | 225 | 0.055 | 327 | 81 | 108 | 126 |

| 1/16 x 1 | 0.0625 | 79.6 | 0.242 | 132 | 187 | 250 | 285 | 0.073 | 247 | 105 | 140 | 160 |

| 1/16 x 1 1/2 | 0.0938 | 119 | 0.362 | 87.7 | 270 | 355 | 410 | 0.110 | 164 | 151 | 199 | 230 |

| 1/16 x 2 | 0.125 | 159 | 0.483 | 65.8 | 345 | 460 | 530 | 0.146 | 123 | 193 | 258 | 297 |

| 1/8 x 1/2 | 0.0625 | 79.6 | 0.241 | 132 | 153 | 205 | 235 | 0.073 | 247 | 86 | 115 | 132 |

| 1/8 x 3/4 | 0.0938 | 119 | 0.362 | 87.7 | 215 | 285 | 325 | 0.110 | 164 | 120 | 160 | 182 |

| 1/8 x 1 | 0.125 | 159 | 0.483 | 65.8 | 270 | 360 | 415 | 0.146 | 123 | 151 | 202 | 232 |

| 1/8 x 1 1/2 | 0.188 | 239 | 0.726 | 43.8 | 385 | 510 | 590 | 0.220 | 82 | 216 | 286 | 330 |

| 1/8 x 2 | 0.25 | 318 | 0.966 | 32.9 | 495 | 660 | 760 | 0.293 | 62 | 277 | 370 | 426 |

| 1/8 x 2 1/2 | 0.312 | 397 | 1.210 | 26.4 | 600 | 800 | 920 | 0.365 | 49 | 336 | 448 | 515 |

| 1/8 x 3 | 0.375 | 477 | 1.450 | 21.9 | 710 | 940 | 1100 | 0.439 | 41 | 398 | 526 | 616 |

| 1/8 x 3 1/2 | 0.438 | 558 | 1.690 | 18.8 | 810 | 1100 | 1250 | 0.512 | 35 | 454 | 616 | 700 |

| 1/8 x 4 | 0.5 | 636 | 1.930 | 16.5 | 900 | 1200 | 1400 | 0.585 | 31 | 504 | 672 | 784 |

| 3/16 x 1/2 | 0.09375 | 119 | 0.362 | 87.7 | 195 | 260 | 300 | 0.110 | 164 | 109 | 146 | 168 |

| 3/16 x 3/4 | 0.141 | 179 | 0.545 | 58.4 | 270 | 360 | 415 | 0.165 | 109 | 151 | 202 | 232 |

| 3/16 x 1 | 0.188 | 239 | 0.726 | 43.8 | 340 | 455 | 520 | 0.220 | 82 | 190 | 255 | 291 |

| 3/16 x 1 1/2 | 0.281 | 358 | 1.090 | 29.3 | 480 | 630 | 730 | 0.329 | 55 | 269 | 353 | 409 |

| 3/16 x 2 | 0.375 | 477 | 1.450 | 21.9 | 610 | 810 | 940 | 0.439 | 41 | 342 | 454 | 526 |

| 3/16 x 2 1/2 | 0.469 | 597 | 1.810 | 17.5 | 740 | 980 | 1150 | 0.549 | 33 | 414 | 549 | 644 |

| 3/16 x 3 | 0.562 | 715 | 2.170 | 14.6 | 870 | 1150 | 1350 | 0.658 | 27 | 487 | 644 | 756 |

| 3/16 x 3 1/2 | 0.656 | 835 | 2.530 | 12.5 | 990 | 1300 | 1500 | 0.768 | 23 | 554 | 728 | 840 |

| 3/16 x 4 | 0.75 | 955 | 2.900 | 11 | 1100 | 1450 | 1700 | 0.878 | 21 | 616 | 812 | 952 |

| 1/4 x 1/2 | 0.125 | 159 | 0.483 | 65.8 | 240 | 315 | 360 | 0.146 | 123 | 134 | 176 | 202 |

| 1/4 x 3/4 | 0.188 | 239 | 0.726 | 43.8 | 320 | 425 | 490 | 0.220 | 82 | 179 | 238 | 274 |

| 1/4 x 1 | 0.25 | 318 | 0.966 | 32.9 | 400 | 530 | 620 | 0.293 | 62 | 224 | 297 | 347 |

| 1/4 x 1 1/2 | 0.375 | 477 | 1.450 | 21.9 | 560 | 740 | 880 | 0.439 | 41 | 314 | 414 | 482 |

| 1/4 x 2 | 0.5 | 637 | 1.930 | 16.5 | 710 | 940 | 1100 | 0.585 | 31 | 398 | 526 | 616 |

| 1/4 x 2 1/2 | 0.625 | 796 | 2.410 | 13.2 | 850 | 1150 | 1300 | 0.731 | 25 | 476 | 644 | 728 |

| 1/4 x 3 | 0.75 | 955 | 2.900 | 11 | 990 | 1300 | 1550 | 0.878 | 21 | 554 | 728 | 868 |

| 1/4 x 3 1/2 | 0.875 | 1110 | 3.380 | 9.4 | 1150 | 1500 | 1750 | 1.024 | 18 | 644 | 840 | 980 |

| 1/4 x 4 | 1 | 1270 | 3.860 | 8.23 | 1250 | 1700 | 1950 | 1.170 | 15 | 700 | 952 | 1092 |

| 1/4 x 5 | 1.25 | 1590 | 4.830 | 6.58 | 1500 | 2000 | 2350 | 1.463 | 12 | 840 | 1120 | 1316 |

| 1/4 x 6 | 1.5 | 1910 | 5.800 | 5.49 | 1750 | 2350 | 2700 | 1.755 | 10 | 980 | 1316 | 1512 |

| 3/8 x 3/4 | 0.281 | 368 | 1.090 | 29.3 | 415 | 550 | 630 | 0.329 | 55 | 232 | 308 | 353 |

| 3/8 x 1 | 0.375 | 477 | 1.450 | 21.9 | 510 | 680 | 790 | 0.439 | 41 | 286 | 381 | 442 |

| 3/8 x 1 1/2 | 0.562 | 715 | 2.170 | 14.6 | 710 | 940 | 1100 | 0.658 | 27 | 398 | 526 | 616 |

| 3/8 x 2 | 0.75 | 955 | 2.900 | 11 | 880 | 1150 | 1350 | 0.878 | 21 | 493 | 644 | 756 |

| 3/8 x 2 1/2 | 0.938 | 1190 | 3.620 | 8.77 | 1050 | 1400 | 1600 | 1.097 | 16 | 5.88 | 784 | 896 |

| 3/8 x 3 | 1.12 | 1430 | 4.350 | 7.35 | 1200 | 1600 | 1850 | 1.310 | 14 | 672 | 896 | 1036 |

| 3/8 x 3 1/2 | 1.31 | 1670 | 5.060 | 6.38 | 1350 | 1800 | 2100 | 1.533 | 12 | 756 | 1008 | 1176 |

| 3/8 x 4 | 1.5 | 1910 | 5.8 | 5.49 | 1500 | 2000 | 2350 | 1.755 | 10 | 840 | 1120 | 1316 |

| 3/8 x 5 | 1.88 | 2390 | 7.26 | 4.38 | 1800 | 2400 | 2800 | 2.2 | 8 | 1008 | 1344 | 1568 |

| 3/8 x 6 | 2.25 | 2860 | 8.69 | 3.66 | 2100 | 2800 | 3250 | 2.633 | 7 | 1176 | 1568 | 1820 |

| 1/2 x 1 | 0.5 | 637 | 1.93 | 16.5 | 620 | 820 | 940 | 0.585 | 31 | 347 | 459 | 526 |

| 1/2 x 1 1/2 | 0.75 | 955 | 2.9 | 11 | 830 | 1100 | 1250 | 0.878 | 21 | 465 | 616 | 700 |

| 1/2 x 2 | 1 | 1270 | 3.86 | 8.23 | 1000 | 1350 | 1550 | 1.17 | 15 | 560 | 756 | 868 |

| 1/2 x 2 1/2 | 1.25 | 1590 | 4.83 | 6.58 | 1200 | 1600 | 1850 | 1.463 | 12 | 672 | 896 | 1036 |

| 1/2 x 3 | 1.5 | 1910 | 5.8 | 5.49 | 1400 | 1850 | 2150 | 1.755 | 10 | 784 | 1036 | 1204 |

| 1/2 x 3 1/2 | 1.75 | 2230 | 6.76 | 4.7 | 1550 | 2100 | 2400 | 2.048 | 9 | 868 | 1176 | 1344 |

| 1/2 x 4 | 2 | 2550 | 7.73 | 4.11 | 1700 | 2300 | 2650 | 2.34 | 8 | 952 | 1288 | 1484 |

| 1/2 x 5 | 2.5 | 3180 | 9.66 | 3.29 | 2050 | 2750 | 3150 | 2.925 | 6 | 1148 | 1540 | 1764 |

| 1/2 x 6 | 3 | 3820 | 11.6 | 2.74 | 2400 | 3150 | 3650 | 3.51 | 5 | 1344 | 1764 | 2044 |

| 1/2 x 8 | 4 | 5090 | 15.5 | 2.06 | 3000 | 4000 | 4600 | 4.68 | 4 | 1680 | 2240 | 2576 |

- **Source: Copper Development Organization https://www.copper.org/applications/electrical/busbar/bus_table1.html

- **Source: Aluminum Association https://www.aluminum.org/sites/default/files/aecd13.pdf

Note: Ratings depend upon configuration, air flow, ambient temp, etc. The values depicted are an approximation. Controlled testing is always required to validate.

Other considerations:

- Forming the busbar (aluminum has a tendacy to crack with very tight radius)

- Electroplating the busbar (white rust on aluminum, oxidation is an issue with aluminum)

- Configuration of the busbar (vertical or horizontal configuration)

HC Aluminum Common sizes of 6101 aluminum busbar

6101 Right Angle Aluminum Busbar

| Thickness A (in) | Width B (in) | Estimated Weight per lb/ft |

| 1/8 | 0.375 | 0.055 |

| 1/8 | 0.500 | 0.074 |

| 1/8 | 0.625 | 0.090 |

| 1/8 | 0.750 | 0.110 |

| 1/8 | 0.875 | 0.127 |

| 1/8 | 1.000 | 0.149 |

| 1/8 | 1.250 | 0.184 |

| 1/8 | 2.000 | 0.299 |

| 1/8 | 2.500 | 0.371 |

| 1/8 | 4.000 | 0.599 |

| 3/16 | 0.375 | 0.084 |

| 3/16 | 0.500 | 0.112 |

| 3/16 | 0.625 | 0.140 |

| 3/16 | 0.750 | 0.168 |

| 3/16 | 0.875 | 0.187 |

| 3/16 | 1.000 | 0.222 |

| 3/16 | 2.000 | 0.442 |

| 1/4 | 0.500 | 0.149 |

| 1/4 | 0.750 | 0.209 |

| 1/4 | 1.000 | 0.284 |

| 1/4 | 1.250 | 0.359 |

| 1/4 | 1.500 | 0.434 |

| 1/4 | 2.000 | 0.584 |

| 1/4 | 2.500 | 0.734 |

| 1/4 | 3.000 | 0.884 |

| 1/4 | 3.250 | 0.959 |

| 1/4 | 4.000 | 1.184 |

| 1/4 | 4.500 | 1.334 |

| 1/4 | 5.000 | 1.484 |

| 1/4 | 6.000 | 1.784 |

| 1/4 | 7.000 | 2.084 |

| 1/4 | 8.000 | 2.384 |

| 3/8 | 0.625 | 0.277 |

| 3/8 | 1.25 | 0.527 |

| 3/8 | 2 | 0.864 |

| 3/8 | 2.5 | 1.120 |

| 3/8 | 3 | 1.134 |

| 3/8 | 4 | 1.764 |

| 3/8 | 5 | 2.214 |

| 3/8 | 6 | 2.664 |

| 3/8 | 8 | 3.596 |

| 1/2 | 0.75 | 0.385 |

| 1/2 | 1.5 | 0.896 |

| 1/2 | 2 | 1.196 |

| 1/2 | 3 | 1.796 |

| 1/2 | 4 | 2.396 |

| 1/2 | 5 | 2.996 |

| 1/2 | 6 | 3.596 |

| 1/2 | 8 | 4.796 |

| 1/2 | 10 | 5.996 |

| 3/4 | 1 | 0.884 |

| 3/4 | 4 | 3.455 |

| 3/4 | 5 | 4.495 |

| 1 | 1.25 | 1.498 |

| 1 | 8 | 9.535 |

| 1 | 10 | 11.996 |

| 1 | 12 | 14.364 |

Rounded Corners 6101 Aluminum Busbar

| Thickness A (in) | Width B (in) | Radius R (in) | Estimated Weight per lb/ft |

| 1/8 | 0.375 | 0.031 | 0.055 |

| 1/8 | 0.5 | 0.016 | 0.074 |

| 1/8 | 0.5 | 0.031 | 0.074 |

| 1/8 | 0.625 | 0.062 | 0.09 |

| 1/8 | 0.75 | 0.031 | 0.11 |

| 1/8 | 0.875 | 0.062 | 0.127 |

| 1/8 | 1 | 0.031 | 0.149 |

| 1/8 | 1.25 | 0.062 | 0.184 |

| 1/8 | 2 | 0.031 | 0.299 |

| 1/8 | 2.5 | 0.031 | 0.371 |

| 1/8 | 4 | 0.031 | 0.599 |

| 3/16 | 0.375 | 0.031 | 0.084 |

| 3/16 | 0.5 | 0.031 | 0.112 |

| 3/16 | 0.625 | 0.031 | 0.14 |

| 3/16 | 0.75 | 0.016 | 0.169 |

| 3/16 | 0.75 | 0.031 | 0.168 |

| 3/16 | 0.875 | 0.094 | 0.187 |

| 3/16 | 1 | 0.062 | 0.222 |

| 3/16 | 2 | 0.094 | 0.442 |

| 1/4 | 0.5 | 0.031 | 0.149 |

| 1/4 | 0.75 | 0.125 | 0.209 |

| 1/4 | 1 | 0.125 | 0.284 |

| 1/4 | 1.25 | 0.125 | 0.359 |

| 1/4 | 1.5 | 0.125 | 0.434 |

| 1/4 | 2 | 0.125 | 0.584 |

| 1/4 | 2.5 | 0.125 | 0.734 |

| 1/4 | 3 | 0.125 | 0.884 |

| 1/4 | 3.25 | 0.125 | 0.959 |

| 1/4 | 4 | 0.125 | 1.184 |

| 1/4 | 4.5 | 0.125 | 1.334 |

| 1/4 | 5 | 0.125 | 1.484 |

| 1/4 | 6 | 0.125 | 1.784 |

| 1/4 | 7 | 0.125 | 2.084 |

| 1/4 | 8 | 0.125 | 2.384 |

| 3/8 | 0.625 | 0.062 | 0.277 |

| 3/8 | 1.25 | 0.188 | 0.527 |

| 3/8 | 2 | 0.062 | 0.895 |

| 3/8 | 2 | 0.187 | 0.864 |

| 3/8 | 2.5 | 0.062 | 1.12 |

| 3/8 | 3 | 0.187 | 1.314 |

| 3/8 | 5 | 0.187 | 2.214 |

| 3/8 | 4 | 0.187 | 1.764 |

| 3/8 | 6 | 0.187 | 2.664 |

| 3/8 | 8 | 0.062 | 3.596 |

| 1/2 | 0.75 | 0.250 | 0.385 |

| 1/2 | 1.5 | 0.062 | 0.896 |

| 1/2 | 2 | 0.062 | 1.196 |

| 1/2 | 3 | 0.062 | 1.796 |

| 1/2 | 4 | 0.062 | 2.396 |

| 1/2 | 5 | 0.062 | 2.996 |

| 1/2 | 6 | 0.062 | 3.596 |

| 1/2 | 8 | 0.062 | 4.796 |

| 1/2 | 10 | 0.062 | 5.996 |

| 3/4 | 1 | 0.125 | 0.884 |

| 3/4 | 4 | 0.375 | 3.455 |

| 3/4 | 5 | 0.062 | 4.495 |

| 1/1 | 1.25 | 0.031 | 1.498 |

| 1/1 | 8 | 0.25 | 9.535 |

| 1/1 | 10 | 0.062 | 11.996 |

| 1/1 | 12 | 0.188 | 14.364 |

Advantages and Disadvantages of 6101 Aluminum Busbars

| Category | Advantages | Disadvantages |

| Weight | 6101 aluminum busbars are lighter than copper busbars, making them easier to install and handle, reducing the burden on support structures. | Although aluminum busbars are lightweight, additional support may be needed in certain high-load situations. |

| Conductivity | 6101 aluminum busbars have good conductivity, making them suitable for most power transmission applications. | The conductivity of aluminum is approximately lower than that of copper. |

| Corrosion Resistance | The oxide film that forms on aluminum surfaces provides good corrosion protection, making it suitable for humid or corrosive environments. | In certain extreme environments, the corrosion resistance of aluminum may be insufficient, requiring additional protective measures. |

| Cost | The raw material cost of aluminum is typically lower than that of copper, making 6101 aluminum busbars more economical for large-scale applications. | Initial investment and installation technical requirements may lead to increased overall costs, especially in cases requiring high-precision connections. |

| Installation and Maintenance | The installation process is relatively straightforward, and aluminum busbars have low maintenance requirements, reducing long-term operating costs. | Connections require specialized skills to ensure good electrical contact and to avoid overheating and oxidation issues. |

Applications of 6101 Aluminum Busbars

| Application Area | Detailed Description |

| Power Distribution Systems | 6101 aluminum busbars are widely used in equipment such as power distribution cabinets and substations as the main channel for power delivery, ensuring effective transmission of electricity from the power source to various loads. |

| Power Distribution | In distribution systems, 6101 aluminum busbars are used to connect transformers, switching devices, and other electrical equipment, providing efficient power transmission to meet the energy needs of different loads. |

| Industrial Applications | In factories and manufacturing, 6101 aluminum busbars are used for electrical wiring and power distribution, particularly suitable for heavy load or high current applications, capable of withstanding power demands under high load conditions. |

| Buildings and Infrastructure | In the electrical systems of large buildings (such as data centers, hospitals, and high-rise buildings), 6101 aluminum busbars provide stable power supply, ensuring the normal operation of critical equipment. |

| Transportation | In rail transit, subways, and electric vehicles, 6101 aluminum busbars serve as power transmission lines, ensuring safe and efficient power supply to support the normal operation of urban transportation. |

Considerations

Although 6101 aluminum alloy offers several advantages, it is important to note that its electrical conductivity is lower than that of pure copper. Therefore, to achieve equivalent current-carrying capacity, a larger cross-sectional area is required. Additionally, aluminum's higher coefficient of thermal expansion compared to copper necessitates careful design to accommodate thermal stresses and prevent loosening of connections over time.

6101 aluminum alloy is a versatile material that balances electrical conductivity with mechanical strength, making it a preferred choice for various electrical applications, especially where weight and cost are significant considerations.