7075 aluminum flat bar

The 7075 aluminum flat bar is a high-strength aluminum alloy material widely used in the aerospace, military, and automotive fields. It is renowned for its excellent strength and lightweight characteristics, combined with the superior corrosion resistance of aluminum, making it an ideal choice for components subjected to significant stress.

Properties of 7075 Aluminum Flat Bar

- High Strength: 7075 aluminum alloy is one of the strongest aluminum alloys, often comparable to certain steels. This makes it very popular in applications requiring high strength and durability.

- Fatigue Strength: 7075 aluminum alloy has good fatigue strength, capable of withstanding repeated loads without easy fatigue failure.

- Lightweight: Compared to steel, 7075 aluminum alloy significantly reduces weight, enhancing overall efficiency and performance, especially in aerospace applications.

- Corrosion Resistance: Although the corrosion resistance of 7075 aluminum alloy is not as high as that of some other aluminum alloys (such as 6061 or 5052), it still surpasses many other metal materials.

- Machinability: The machinability of 7075 aluminum alloy is moderate, suitable for machining, but it is not weldable, as welding can lead to reduced strength.

HC Aluminum 7075 Aluminum Flat Bar Specifications

- Available shapes: Flats, squares, and rounds

- Tempers: T6, T651, T73, T7351

- Specifications: ASTM B211, AMS 4122, AMS 4123, AMS 4124, AMS 4186, AMS-QQ-A-225/9, ASTM B221, AMS 4154, AMS 4166, AMS 4167, AMS-QQ-A-200/11

Heat Treatment States:

- 7075-T651: Solution heat-treated and artificially aged, with the highest strength.

- 7075-T6511: Similar to T651 but with additional treatment to enhance toughness.

- 7075-T7351: Exhibits excellent strength and fatigue resistance, suitable for high-demand applications.

- 7075-T3511: Heat-treated, suitable for applications requiring good strength and toughness.

- 7075-T76511: Specially treated to enhance corrosion resistance and strength, suitable for extreme environments.

HC Aluminum offers 7075 aluminum flat bars in full sizes and custom cut lengths to meet specific customer needs. Whether standard sizes or special requirements, we provide high-quality 7075 aluminum products, ensuring they meet the performance requirements of various applications.

7075 is one of the highest-strength aluminum alloys. It has good fatigue strength and average machinability, typically used in areas where parts experience significant stress. It is not weldable and has lower corrosion resistance compared to other aluminum alloys. Mechanical properties depend on the material's temper. We have 7075-T651, 7075-T6511, 7075-T7351, 7075-T3511, and 7075-T76511 in stock.

7075 aluminum flat bar Typical Chemical Composition

| Typical Chemical Composition % | ||||||||||

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 1.20 | 2.10 | 0.18 | 5.10 | ||||||

| Maximum | 0.40 | 0.50 | 2.00 | 0.30 | 2.90 | 0.28 | 6.10 | 0.20 | 0.05 | 0.15 |

Remainder Aluminum

7075 aluminum flat bar Typical Mechanical Properties

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T6, T651 | 83 | 572 | 73 | 503 | 11 | 150 |

| T73, T7351 | 73 | 503 | 63 | 434 | 13 | N/A |

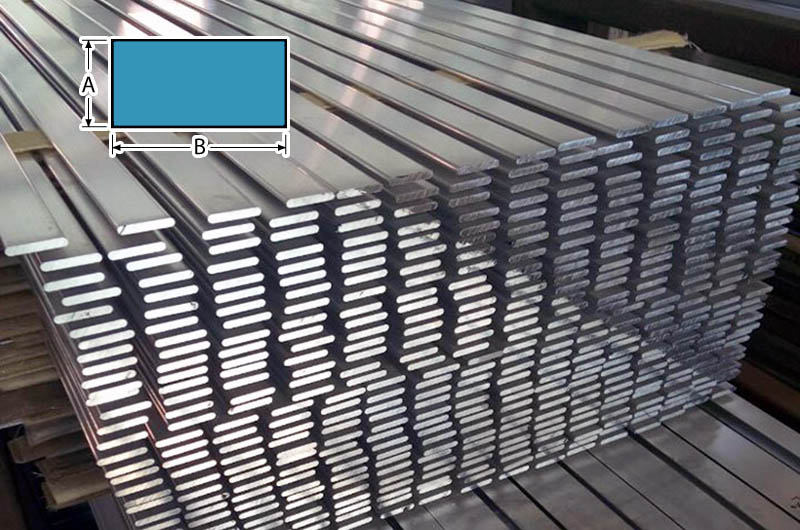

HC 7075 aluminum flat bar stock

| Description | A(inch) | B(inch) |

| 0.125(A) X 1/4(B) inch 7075 t6 aluminum flat bar | 0.125 | 1/4 |

| 0.188(A) X 1/4(B) inch 7075 t6 aluminum flat bar | 0.188 | 1/4 |

| 0.25(A) X 1/4(B) inch 7075 t6 aluminum flat bar | 0.25 | 1/4 |

| 0.125(A) X 1/2(B) thick 7075 t6 aluminum flat bar | 0.125 | 1/2 |

| 0.188(A) X 1/2(B) thick 7075 t6 aluminum flat bar | 0.188 | 1/2 |

| 0.25(A) X 1/2(B) thick 7075 t6 aluminum flat bar | 0.25 | 1/2 |

| 0.313(A) X 1/2(B) thick 7075 t6 aluminum flat bar | 0.313 | 1/2 |

| 0.375(A) X 1/2(B) thick 7075 t6 aluminum flat bar | 0.375 | 1/2 |

| 0.5(A) X 1/2(B) thick 7075 t6 aluminum flat bar | 0.5 | 1/2 |

| 0.125(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.125 | 2 |

| 0.188(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.188 | 2 |

| 0.25(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.25 | 2 |

| 0.313(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.313 | 2 |

| 0.375(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.375 | 2 |

| 0.5(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.5 | 2 |

| 0.625(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.625 | 2 |

| 0.75(A) X 2(B) inch 7075 t6 aluminum flat bar | 0.75 | 2 |

| 1(A) X 2(B) inch 7075 t6 aluminum flat bar | 1 | 2 |

| 1.25(A) X 2(B) inch 7075 t6 aluminum flat bar | 1.25 | 2 |

| 1.5(A) X 2(B) inch 7075 t6 aluminum flat bar | 1.5 | 2 |

| 1.75(A) X 2(B) inch 7075 t6 aluminum flat bar | 1.75 | 2 |

| 2(A) X 2(B) inch 7075 t6 aluminum flat bar | 2 | 2 |

| 0.125(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.125 | 3 |

| 0.188(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.188 | 3 |

| 0.25(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.25 | 3 |

| 0.313(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.313 | 3 |

| 0.375(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.375 | 3 |

| 0.5(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.5 | 3 |

| 0.625(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.625 | 3 |

| 0.75(A) X 3(B) inch 7075 t6 aluminum flat bar | 0.75 | 3 |

| 1(A) X 3(B) inch 7075 t6 aluminum flat bar | 1 | 3 |

| 1.25(A) X 3(B) inch 7075 t6 aluminum flat bar | 1.25 | 3 |

| 1.5(A) X 3(B) inch 7075 t6 aluminum flat bar | 1.5 | 3 |

| 1.75(A) X 3(B) inch 7075 t6 aluminum flat bar | 1.75 | 3 |

| 2(A) X 3(B) inch 7075 t6 aluminum flat bar | 2 | 3 |

| 2.25(A) X 3(B) inch 7075 t6 aluminum flat bar | 2.25 | 3 |

| 2.5(A) X 3(B) inch 7075 t6 aluminum flat bar | 2.5 | 3 |

| 3(A) X 3(B) inch 7075 t6 aluminum flat bar | 3 | 3 |

| 3.5(A) X 3(B) inch 7075 t6 aluminum flat bar | 3.5 | 3 |

| 0.125(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.125 | 4 |

| 0.188(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.188 | 4 |

| 0.25(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.25 | 4 |

| 0.313(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.313 | 4 |

| 0.375(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.375 | 4 |

| 0.5(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.5 | 4 |

| 0.625(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.625 | 4 |

| 0.75(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 0.75 | 4 |

| 1(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 1 | 4 |

| 1.25(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 1.25 | 4 |

| 1.5(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 1.5 | 4 |

| 1.75(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 1.75 | 4 |

| 2(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 2 | 4 |

| 2.25(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 2.25 | 4 |

| 2.5(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 2.5 | 4 |

| 3(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 3 | 4 |

| 3.5(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 3.5 | 4 |

| 4(A) X 4(B) inch wide 7075 t6 aluminum flat bar | 4 | 4 |

Applications of 7075 Aluminum Flat Bar

7075 aluminum alloy is a high-strength aluminum alloy widely used in various fields, particularly in the aerospace, military, and automotive industries.

1. Aerospace

7075 aluminum alloy is extensively used in the aerospace field due to its excellent strength and rigidity, especially in aircraft structural components. Specific applications include:

Aircraft Structural Components: 7075 aluminum alloy is commonly used in the wing frames, fuselage structures, tail assemblies, and other load-bearing components of aircraft. These components require high strength to withstand various pressures and loads during flight while also needing to reduce weight to improve fuel efficiency and flight performance.

Landing Gear: 7075 aluminum alloy plays a crucial role in the landing gear systems of aircraft. The landing gear must withstand significant impact forces during landing and takeoff, so high-strength materials are required to ensure safety and durability.

Components and Connectors: 7075 aluminum alloy is also used to manufacture various connectors, brackets, and accessories for aircraft. Its good fatigue resistance and weldability allow these components to maintain good performance over long periods of use.

2. Military

7075 aluminum alloy is widely used in the construction of military aircraft, helicopters, and drones. These devices need to operate under extreme conditions, requiring very high strength and durability from the materials.

In tanks, armored vehicles, and other combat vehicles, 7075 aluminum alloy is used in the vehicle body structures, armor plates, and suspension systems. Using 7075 aluminum alloy can reduce the weight of the vehicle, thus improving its maneuverability and fuel efficiency without sacrificing protection.

3. Automotive

High-Performance Components: 7075 aluminum alloy is used to manufacture key components in race cars and high-performance vehicles, such as frames, suspension systems, and engine parts. Its high strength and low weight characteristics help improve overall vehicle performance, enhancing acceleration and handling.

Structural Components: In some luxury passenger cars, 7075 aluminum alloy is also used in body structural components to help reduce overall vehicle weight, thereby improving fuel economy and reducing emissions.

Safety Components: 7075 aluminum alloy is used in the safety systems of some vehicles, such as crash beams, which need to provide protection during collisions while maintaining sufficient strength and toughness.