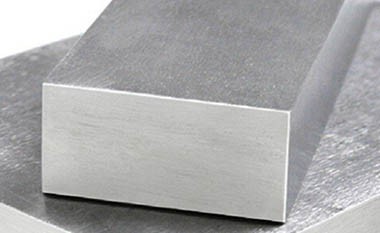

7075 t6 aluminum block

7075 aluminum blocks belong to the Al-Zn-Mg-Cu ultra-high-strength alloy category. They are a cold-forging alloy with high strength and hardness. This alloy exhibits excellent mechanical properties and anodic reaction, making it a typical aluminum alloy material used in the aerospace industry, molds, engines, and equipment.

7075 aluminum blocks are cut from hot-rolled plates or extruded circular or square blocks. We can provide custom-sized aluminum blocks. These blocks are widely used in mold, stamping, or component manufacturing.

About 7075 T6 Aluminium Blocks

7075 T6 aluminum blocks are high-strength aluminum alloys belonging to the aluminum-zinc-magnesium-copper series. 7075 T6 aluminum blocks can be produced through processes such as hot rolling, extrusion, and cutting. They are typically available in the form of hot-rolled plates or extruded circular and square blocks, suitable for subsequent processing and forming.

7075 T6 Aluminum Block Features

- 1. Strength and Hardness: The tensile strength of 7075 T6 aluminum alloy can reach over 570 MPa, and the hardness is usually above 150 HB, making it suitable for applications that bear high loads.

- 2. Corrosion Resistance: Although the corrosion resistance of 7075 alloy is relatively weak, it can be significantly improved through anodic oxidation treatment.

- 3. Good Machinability: 7075 T6 aluminum blocks maintain good machinability after cold forging and heat treatment, making them suitable for various manufacturing processes.

7075 t6 aluminum block Specifications

| Specifications | Details |

| Alloy | 7075 |

| Condition | T6, T651 |

| Processing Method | Extrusion, forging, cut from blocks, circular blocks, square blocks, rectangular blocks |

| Standards | EN 485, EN 573, ASTM B209, ASTM B221 |

| Thickness | 6MM to 300MM |

| Width | 100mm to 2600mm, custom widths can be cut from blocks |

| Length | 500mm to 16000mm, custom lengths available |

| Available Sizes | Blocks, circular blocks, rectangular blocks can be cut to size as requested |

| Surface Treatment | Mill finish, polishing, precision polished blocks, anodizing |

| Test Certificates | According to EN 10204 3.1, third-party inspection, buyer inspection |

| Packaging | Wooden pallets or custom pallets |

Advantages of 7075 T6 Aluminum Blocks

1. Stable Machinability

7075 T6 aluminum blocks, when machined after stress relief, effectively avoid deformation and warping. All ultra-thick 7075 aluminum blocks undergo ultrasonic testing to ensure there are no sand holes or impurities, enhancing the material's consistency and reliability. Additionally, 7075 aluminum blocks have high thermal conductivity, which reduces molding time and significantly improves machining efficiency.

2. Excellent Physical Properties

7075 aluminum blocks exhibit exceptional physical properties, including good strength, hardness, and tensile performance. Their machinability is also outstanding, adaptable to various machining methods. At the same time, 7075 aluminum blocks have good corrosion resistance, especially after aging hardening treatment, which allows for higher strength while maintaining excellent performance in harsh environments.

3. High Strength Natural Aging

Even under natural aging conditions, 7075 aluminum blocks can achieve high strength with low sensitivity to cracking. This means that during machining and use, 7075 aluminum blocks can withstand greater stress without easily developing cracks or other defects, thereby enhancing their reliability in various applications.

4. Weld Strength Recovery

During welding, the heat from the welding area can cause localized material melting in 7075 aluminum blocks. However, after natural aging, the strength of these welded areas can be restored. This characteristic results in high weld strength for 7075 aluminum blocks, making them suitable for applications requiring welding, ensuring the overall structural safety and reliability.

Popular 7075 T6 Aluminum Blocks at HC Aluminum

-

Aluminium 7075 T6 Round Blocks

Specifications: Round blocks of various diameters can be provided according to customer requirements. Applications: Widely used for manufacturing high-strength components, aerospace structures, and high-performance molds. Features: Excellent tensile strength and hardness, suitable for bearing high loads, with good thermal conductivity that helps shorten processing time.

-

Aluminium 7075 T6 Square Blocks

Specifications: Square blocks of different side lengths can be provided as required. Applications: Commonly used for manufacturing structural components, mechanical parts, and high-strength molds. Features: Achieves high strength after aging hardening treatment, with strong crack resistance, suitable for use in harsh environments.

-

Aluminium 7075 T6 Rectangular Blocks

Specifications: Rectangular blocks of various widths and thicknesses can be provided according to customer requirements. Applications: Suitable for aerospace, vehicle frameworks, machining, and other fields requiring high-strength materials. Features: Good corrosion resistance and machinability, with strength recovery after welding, making them suitable for welded connections in complex structures.

Chemical Composition of Aluminium 7075 T6/T651 Blocks

| Alloy 7075 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Others | Al | |

| Single | Total | |||||||||||

| (%) | 0.4 | 0.5 | 1.2-2 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | – | 0.05 | 0.15 | remainder |

Equivalents of AA 7075

UNS A97075, ISO AlZn5.5MgCu, Aluminium 7075, AA7075, Al7075

7075 T6 Aluminum Block Applications

7075 T6 aluminum alloy is a high-strength aluminum alloy widely used in various fields due to its excellent mechanical properties and corrosion resistance.

1. 7075 T6 Aluminum Billet

7075 T6 aluminum billets are the basic form of aluminum for processing, suitable for machining and casting. Due to its strength and hardness, 7075 aluminum billets are commonly used to manufacture high-strength components, ideal for applications requiring wear resistance and impact resistance.

2. Aerospace Aluminum Blocks 7075 T6

7075 T6 aluminum alloy has significant applications in the aerospace field, primarily used for manufacturing aircraft structural components. These parts require an optimal balance between high strength and low weight, and 7075 T6 can meet these stringent requirements.

3. Molds

7075 T6 aluminum alloy is widely used in the manufacturing of molds, especially injection molds and die-casting molds. Its excellent machinability and heat resistance make it an ideal material for high-performance molds, enhancing the lifespan and precision of the molds.

4. Equipment

In industrial equipment manufacturing, 7075 T6 aluminum alloy is used to produce high-strength and lightweight components. Its strength and rigidity ensure the stability and durability of the equipment during use.

5. Engine Blocks

7075 T6 aluminum alloy is suitable for manufacturing high-performance engine blocks, especially in racing and aviation engines. Its high strength and low density contribute to increased power and efficiency while reducing overall weight.

6. Vehicle Hubs

7075 T6 aluminum alloy is also used for aluminum alloy wheels in vehicles, particularly in high-performance and racing applications. Its lightweight and strength enhance vehicle handling and acceleration while providing excellent corrosion resistance.

Frequently Asked Questions about 7075 T6 Aluminum Blocks

Is 7075-T6 aluminum stronger than steel?

Although 7075-T6 aluminum is much stronger than many aluminum alloys, it is generally not stronger than structural steel.

What is better, 7075-T6 or 6061 T6?

| Characteristics/Questions | 7075-T6 Aluminum Alloy | 6061-T6 Aluminum Alloy |

| Strength | Higher | Lower |

| Corrosion Resistance | Poorer | Better |

| Weldability | Poorer | Better |

| Machinability | More Difficult | Easier |

| Main Applications | Aerospace, Military, Automotive, High-Performance Sporting Equipment | Construction, Automotive, General Industrial Applications |

| Forming Methods | Forging, Extrusion | Extrusion, Milling |

| Usage Range | Aircraft Structures, Military Equipment, Molds, Sports Equipment | Building Materials, Mechanical Parts, Frames, etc. |

What is 7075-T6 aluminum used for?

| Application Areas | Specific Applications |

| Aerospace | Aircraft Fuselages, Wing Beams, Tail Sections |

| Military Equipment | Firearms, Tactical Gear |

| Automotive | High-Performance Components, Chassis |

| Marine | Hull Frames |

| Sports Equipment | Bicycles, Climbing Gear |

| Manufacturing Molds | Injection Molds, Die-Casting Molds |

Is forged 7075-T6 aluminum good?

| Advantages | Description |

| Strength | Increased strength and toughness, suitable for high-pressure applications |

| Fatigue Resistance | Improved fatigue tolerance |

| Reliability | Superior performance under extreme conditions |