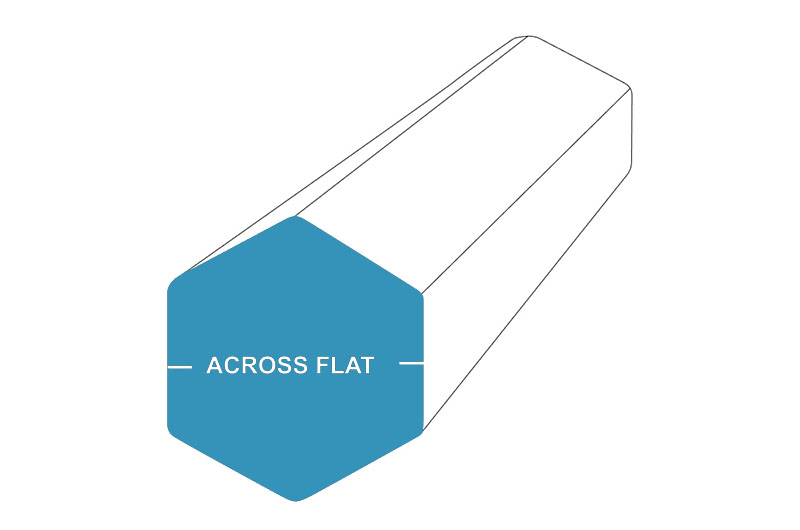

Aluminum Hexagonal Bar

Aluminum hexagonal bar is an aluminum alloy profile with a hexagonal cross-section, widely used in aerospace, mechanical processing, electronic devices, and structural components. Its main characteristics include excellent corrosion resistance, lightweight, good machinability, and high strength, making it suitable for applications that require high material performance.

HC Aluminum's aluminum hexagonal bars come in a variety of specifications and sizes, usually customized based on customer needs. Standard sizes generally include different diameters and lengths to meet various engineering requirements.

Aluminum Hexagonal Bar Characteristics

- Corrosion Resistance: Aluminum alloys have natural corrosion resistance, especially certain alloys like 6061 and 7075, whose surface oxide film can effectively prevent oxidation and extend the material's lifespan.

- Lightweight: Aluminum alloys have a low density, making aluminum hexagonal bars the preferred material for many applications that require lightweight materials (such as aerospace, transportation equipment, etc.).

- Strength: The strength of different aluminum alloys varies, with some alloys like 7075 and 2024 offering higher strength, making them suitable for components that need to withstand significant loads.

- Good Machinability: Aluminum hexagonal bars have good cutting and welding properties, suitable for machining into required shapes through turning, milling, and other processes to meet various industrial needs.

- Low Maintenance: Due to aluminum's excellent corrosion resistance and relatively low density, aluminum hexagonal bars require less maintenance, reducing long-term maintenance costs.

Common Aluminum Alloy Hexagonal Bars

2011 Aluminum Alloy Hexagonal Bar

- Characteristics: 2011 aluminum alloy is a high-strength, good machinability, and formability alloy, often used to manufacture precision mechanical parts. Its corrosion resistance is relatively weak but performs well in many light-load applications.

- Applications: Mainly used in precision components, mechanical processing, and electronic device housings, where surface treatment requirements are not high.

2024 Aluminum Alloy Hexagonal Bar

- Characteristics: 2024 aluminum alloy is widely used in aerospace due to its high strength, fatigue resistance, and good corrosion resistance. It has high tensile strength and good weldability.

- Applications: Primarily used in aerospace, military, structural support components, aircraft frames, wings, and other parts that need to withstand significant stress.

6061 Aluminum Alloy Hexagonal Bar

- Characteristics: 6061 aluminum alloy is one of the most common industrial aluminum alloys, with good mechanical properties, corrosion resistance, and weldability. It has slightly lower strength than 2024 but better formability and machinability.

- Applications: Widely used in construction, transportation, mechanical structures, aerospace, and automotive industries, suitable for making frames, supports, pipes, and other components.

6262 Aluminum Alloy Hexagonal Bar

- Characteristics: 6262 aluminum alloy has excellent machinability and higher strength, suitable for complex machining. Its corrosion resistance is good, and its strength is moderate, making it suitable for many lightweight structural components.

- Applications: Widely used in precision components, bolts, fittings, and the precision machinery industry.

7075 Aluminum Alloy Hexagonal Bar

- Characteristics: 7075 aluminum alloy is a high-strength aluminum alloy with excellent strength and corrosion resistance, particularly suitable for heavy-duty and high-strength applications. Although its corrosion resistance and formability are not as good as 6061, it still meets most industrial needs.

- Applications: 7075 aluminum alloy hexagonal bars are commonly used in aerospace, military, sports equipment, and other fields, especially in aircraft structural components, aircraft frames, and military equipment.

Aluminum Hexagonal Bar Applications

- Aerospace: Due to its lightweight, high strength, and corrosion resistance, aluminum hexagonal bars are widely used in aircraft structural components, engine brackets, wing frames, and other fields.

- Automotive Industry: Aluminum hexagonal bars are used to make automotive chassis, engine supports, wheel rims, and other components to reduce weight and improve fuel efficiency.

- Mechanical Processing: The machinability of aluminum hexagonal bars makes them ideal materials for various mechanical structures, precision instruments, electronic components, and other parts.

- Construction and Structures: Due to their strength and corrosion resistance, aluminum hexagonal bars are also widely used in construction supports, steel structure connectors, window and door frames, and other applications.

- Electronics and Electrical: Used in electronic devices' housings and components, such as electronic connectors, plugs, and terminals.

Processing Methods

Aluminum hexagonal bars can be processed through various methods, including:

- Turning: Using a lathe to machine the hexagonal bar into the required dimensions and shapes, suitable for manufacturing small batches of precision components.

- Milling: Using a milling machine for more complex cutting operations to manufacture complex geometric shapes.

- Welding: Although some aluminum alloys (such as 7075) have poor weldability, most aluminum alloy hexagonal bars (such as 6061) can still be welded, suitable for assembling large structural components.

- Anodizing: Anodizing treatment can improve the corrosion resistance and surface hardness of aluminum alloys and enhance their appearance.

Aluminum hexagonal bars are versatile materials suitable for various fields, offering a range of alloy options to meet different strength, corrosion resistance, and machinability requirements.