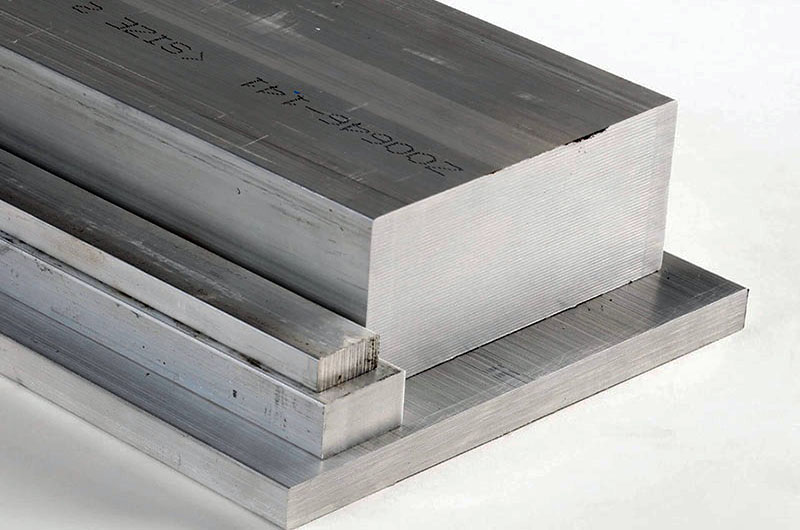

Aluminum Rectangle Bar

Aluminum Rectangle Bar is a widely used aluminum material in various manufacturing and engineering projects, known for its lightweight, corrosion resistance, and ease of processing. Aluminum rectangle bars are typically extruded from aluminum alloys and have a flat surface with square corners, making them easy to weld, cut, and process for various applications.

HC Aluminum provides high-quality aluminum rectangle bars made from top-grade aluminum alloys, ensuring excellent performance and high-precision dimensions. These bars are widely used in various industries to meet customers' requirements for product performance and size.

Typical Aluminum Rectangle Bar Material Choices

- 6061 Aluminum Alloy: 6061 is a widely used aluminum alloy, especially suitable for manufacturing structural components. It has high strength, good corrosion resistance, and weldability, making it ideal for applications requiring hardness and strength. 6061 aluminum rectangle bars can typically be made up to 3 inches in thickness.

- 6063 Aluminum Alloy: 6063 is a softer, more formable aluminum alloy, typically used for applications requiring good formability and lower strength. It has good surface finishing properties, making it suitable for construction, decoration, and applications where appearance is important. 6063 aluminum rectangle bars are generally no thicker than 1/2 inch.

Below is a comparison table between 6061 Aluminum Rectangle Bar and 6063 Aluminum Rectangle Bar:

| Properties | 6061 Aluminum Rectangle Bar | 6063 Aluminum Rectangle Bar |

| Machinability | Good machinability | Good machinability |

| Weldability | Good weldability | Not suitable for welding |

| Formability | Fair | Good formability |

| Corrosion Resistance | Good corrosion resistance | Excellent corrosion resistance |

| Surface Quality | Good surface quality | Excellent surface quality |

| Strength-to-Weight Ratio | Excellent strength-to-weight ratio | Poor strength-to-weight ratio |

Aluminum Rectangle Bar Sizes

The size of aluminum rectangle bars can typically be customized based on application needs, including width, thickness, and length. HC Aluminum provides a range of standard sizes, as well as custom-cut lengths according to customer specifications.

Common sizes range from widths of 1 inch to 12 inches, with thicknesses ranging from 1/8 inch to 3 inches. Larger sizes can be achieved through multi-stage forming processes.

Aluminum Rectangle Bar Features

Lightweight

Aluminum rectangle bars are much lighter than traditional materials like steel, offering a significant weight advantage. This makes them widely used in aerospace, transportation, construction, and other industries, particularly for weight-sensitive projects.

Corrosion Resistance

The natural oxide film on aluminum provides excellent corrosion resistance, especially in marine environments and humid climates, where its performance is particularly strong. Both 6061 and 6063 alloys have good corrosion resistance, making them suitable for use in marine, chemical, and exterior structural components.

Machinability

6061 aluminum alloy has good machinability and can be milled, drilled, cut, bent, and welded in various ways, making it suitable for precision industrial machining needs.

6063 aluminum alloy is relatively softer and has good formability, making it ideal for deep extrusion and processing complex shapes, especially in the construction and decoration industries.

Surface Treatment

The surface of aluminum rectangle bars can be anodized to enhance corrosion resistance and surface hardness, while also providing a variety of colors (such as silver, black, gold, etc.). Additionally, spraying, sanding, and coating processes can be applied to improve appearance and protective properties.

Aluminum Rectangle Bar Applications

Aerospace

Due to its lightweight, high strength, and corrosion resistance, aluminum rectangle bars are widely used in aircraft structural components, interior parts, fuselage frames, wing supports, door frames, and other components.

Automotive Industry

Used for automotive frames, brackets, doors, window frames, and other components. 6061 and 6063 aluminum rectangle bars have excellent mechanical properties and lightweight characteristics, making them ideal for lightweight vehicle structural materials.

Construction and Decoration

Aluminum rectangle bars are commonly used in construction for window frames, door frames, stair railings, guardrails, and exterior wall decorations because they are not only lightweight and durable but also have good surface finishing properties suitable for various decorative styles.

Mechanical Equipment and Industrial Applications

Used to manufacture various mechanical parts, such as brackets, bases, frames, support columns, machine tool components, and more. The 6061 alloy is especially suitable for mechanical structural components requiring high strength and durability.

Marine and Shipbuilding

Due to its excellent corrosion resistance, aluminum rectangle bars are widely used in ship structural components, marine platforms, oil rig equipment, ship frames, and other marine parts.

Other Applications

It can also be used for manufacturing furniture, appliances, lightweight fixtures, electronic accessories, precision instruments, and more.

Aluminum Rectangle Bar Advantages

- Lightweight and high strength: Provides a low-density solution while maintaining strength and stability.

- Corrosion resistance: Suitable for use in harsh environments, particularly in marine and chemical industries.

- Excellent machinability: Suitable for various machining processes and easy to customize.

- Versatile sizes and customization capabilities: Adapts to different application requirements with flexible custom services.