Half Oval aluminum bar

The Half Oval Aluminum Bar is a versatile and decorative aluminum product characterized by its half-oval cross-section. Its elegant profile combines strength and aesthetic appeal, making it suitable for functional and decorative applications across various industries.

HC Aluminum's half-oval aluminum bars come in various lengths, widths, and heights, offering durability and aesthetic appeal. They are ideal for use in decorative woodworking, store fixtures, elevators, store displays, as well as glass and mirror projects.

Additionally, these half-oval aluminum bars can be widely used in various settings, such as cockpits, flybridges, sterns, bulkheads, hatches, and interior cabinets, meeting the requirements of areas needing decorative or functional finishing.

Half Oval aluminum bar Surface Finishes

Standard Mill Finish: Ideal for general purposes and economical applications.

Polished Finish: Provides a smooth and reflective surface for aesthetic uses.

Anodized or Brite Clear Finish: Enhances corrosion resistance and durability while maintaining a shiny, clear appearance.

Custom Finishes: Includes:

Satin or transparent anodized surfaces for subtle elegance.

Brite Dipped Finish for a mirror-like effect.

Bronze or Black Anodized Finish for stylish or contrasting decorative elements.

Half Oval aluminum bar Sizes and Options

Available in various lengths, widths, and heights to meet specific design and functional requirements.

Can be cut or customized to suit unique project needs.

Popular sizes

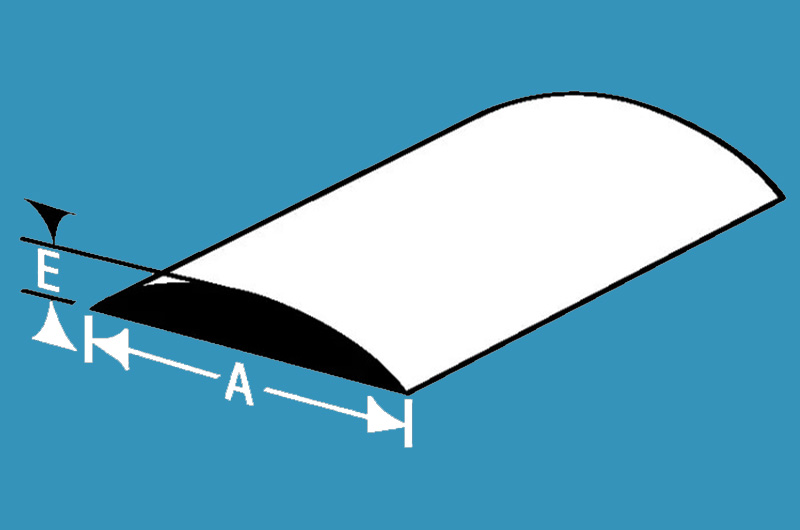

Half oval aluminum bar size measurement: E x A

- Aluminum Half Oval – 1/8″ Half Oval x 7/16″ Face

- Aluminum Half Oval – 3/16″ Half Oval x 1/2″ Face

- Aluminum Half Oval – 3/16″ Half Oval x 3/4″ Face

- Aluminum Half Oval – 3/16″ Half Oval x 1″ Face

- Aluminum Half Oval – 1/4″ Half Oval x 2″ Face

- Aluminum Half Oval – 9/64″ Half Oval x 3/8″ Face

- Aluminum Half Oval – 9/64″ Half Oval x 1/2″ Face

- Aluminum Half Oval – 9/64″ Half Oval x 11/16″ Face

- Aluminum Half Oval – 3/16″ Half Oval x 3/4″ Face

Common Materials for Half Oval Aluminum Bars

1. 6063 Aluminum Alloy

- Features: Known for its excellent extrudability and surface finishing properties, 6063 aluminum alloy offers good corrosion resistance and moderate strength. It is easy to process and capable of forming complex shapes.

- Applications: Widely used in architectural decorations, interior furnishings, frames, and display racks, especially in projects requiring aesthetic and decorative qualities.

2. 6061 Aluminum Alloy

- Features: 6061 aluminum alloy provides high strength, excellent corrosion resistance, and good mechanical properties, making it suitable for applications requiring heavy loads. It also offers excellent weldability and machinability.

- Applications: Suitable for elevators, marine interiors, and other decorative components requiring high strength, often used in industrial and architectural fields.

3. 3003 Aluminum Alloy

- Features: Renowned for its excellent corrosion resistance and formability, 3003 aluminum alloy has lower strength but performs well in many decorative applications.

- Applications: Commonly used in decorative projects, marine furnishings, or light functional finishes, suitable for applications where strength is not critical but appearance and corrosion resistance are essential.

4. 5052 Aluminum Alloy

- Features: 5052 aluminum alloy offers high corrosion resistance and moderate strength, making it ideal for marine environments and humid areas with strong weather resistance.

- Applications: Widely used in ship bulkheads, hatch decorations, and exterior finishes, suitable for environments requiring both corrosion resistance and strength.

5. 7075 Aluminum Alloy (Special Requirements)

- Features: Known for its exceptional strength and good corrosion resistance, 7075 aluminum alloy is suitable for high-load applications. Although its machinability is relatively lower, it excels in applications requiring both strength and aesthetics.

- Applications: Commonly used in the aerospace industry and high-end decorative scenarios, suitable for applications combining strength and decoration, such as aerospace components and high-end furniture.

Features of Half Oval Aluminum Bars

| Feature | Description |

| Durability | Premium aluminum material: Typically made from high-strength aluminum alloys (e.g., 6061, 6063, 7075), offering excellent mechanical properties and a high strength-to-weight ratio. |

| Fatigue resistance: Outstanding fatigue resistance under repeated loads, suitable for vibration and impact environments. | |

| High-temperature stability: Certain aluminum alloys (e.g., 6082) maintain high strength under medium to high temperatures. | |

| Lightweight | Low density: Aluminum's density is 2.7 g/cm³, about one-third that of steel, ideal for applications requiring weight reduction. |

| Easy to transport and install: Lightweight, making it easier to process, handle, and install, saving labor and transportation costs. | |

| Corrosion Resistance | Natural oxide layer: Aluminum naturally forms a dense oxide film on its surface, providing good corrosion resistance. |

| Anodizing treatment: Enhances corrosion resistance, suitable for humid, salt spray, or acid rain environments. | |

| Chemical resistance: Performs well in environments involving acids, alkalis, and various chemical reagents. | |

| Aesthetic Appeal | Various surface treatments: Can undergo brushing, polishing, sandblasting, powder coating, anodizing, or chrome plating to provide diverse decorative effects. |

| Strong decorative performance: Lustrous and smooth texture, suitable for home decor, exhibitions, and artistic decorations. | |

| Color options: Anodizing offers various color choices, such as gold, silver, black, and champagne. |

Applications of Half Oval Aluminum Bars

| Application Field | Specific Use | Description |

| Architectural and Decorative Uses | Woodworking decoration | Half-oval aluminum bars can be used as decorative edges for custom furniture or cabinets, adding visual layers and a modern feel. Their smooth surface and diverse surface treatments (e.g., anodizing and coating) allow seamless integration with wood for enhanced overall design. |

| Store fixtures | In retail displays, half-oval aluminum bars can serve as display racks, frames, or hangers, providing stable support and enhancing the store's visual appeal. Their lightweight nature makes installation and adjustment more convenient. | |

| Elevator components | Half-oval aluminum bars can be used in elevator interior designs, offering a modern and refined appearance. Using aluminum reduces the overall weight of the elevator while maintaining a durable and attractive look over time. | |

| Glass and mirror projects | In glass and mirror installations, half-oval aluminum bars can be used as decorative trims or functional supports, ensuring structural stability while enhancing decorative appeal. Their unique shape and surface treatments add a touch of style to the space. | |

| Marine and Nautical Applications | Cockpits and flybridges | Half-oval aluminum bars provide stylish and durable decorations for cockpits and flybridges, resisting corrosion and wear caused by marine environments. Their lightweight and high-strength characteristics ensure greater safety and aesthetics in nautical settings. |

| Cabin interiors | In ship cabins, half-oval aluminum bars can be used as decorative edges, enhancing overall aesthetic value while protecting surfaces. Aluminum's corrosion resistance makes it ideal for marine environments, reducing maintenance frequency. | |

| Bulkheads and hatches | Used on bulkheads and hatches, half-oval aluminum bars not only provide decorative appeal but also function as structural reinforcements, enhancing strength and stability. Their unique design adds a modern touch to vessels. | |

| Beams and cabinets | In ship beams and cabinet designs, half-oval aluminum bars combine practicality and design, providing sturdy support while maintaining an attractive appearance. Their lightweight nature helps reduce the overall weight of the vessel, improving navigation efficiency. |