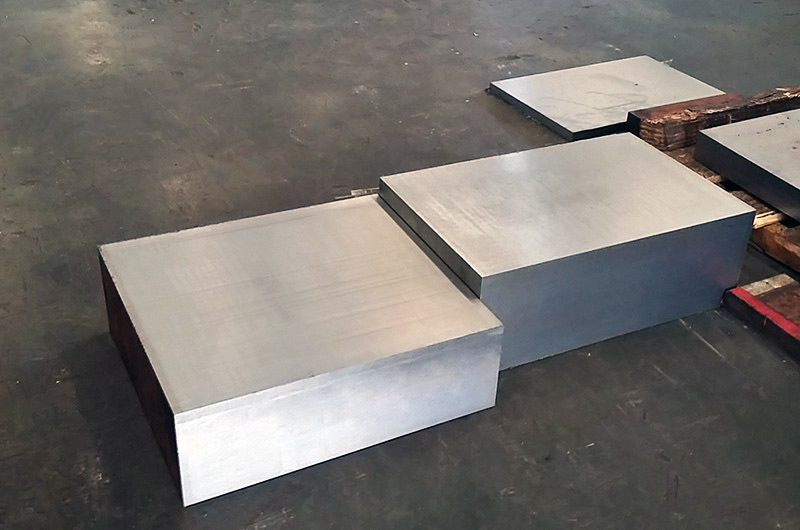

Solid aluminum block

Solid aluminum blocks are metal materials made from pure aluminum or aluminum alloys, typically cut from aluminum sheets or plates using pressure processing techniques (such as shearing or sawing). They can take various shapes, including rectangular, square, or circular, and feature uniform thickness, offering good mechanical properties and corrosion resistance.

Solid aluminum blocks are produced by cutting pure aluminum sheets or aluminum alloy plates through pressure processing (shearing or sawing) into profiles that are rectangular, square, or circular with uniform thickness.

Shapes and Specifications of Solid Aluminum Blocks

- Shape: Common shapes include rectangular, square, and circular.

- Size: Thickness, width, and length can be customized according to customer requirements, typically offering a wide range of sizes to suit different applications.

- Surface Treatment: Solid aluminum blocks can undergo anodizing, electroplating, spraying, and other surface treatments to enhance their appearance and corrosion resistance.

| Main alloys | 1070, 1060, 2024, 2A12, 2011, 3003, 5052, 5083, 5754, 5454, 5A05, 5A06, 6061, 6063, 6082, 7075, 7005, 7020 etc. |

| Thickness | 8-600mm |

| Width | More than 200mm width or according to customer requirements. |

| Length | Within 16m or according to customer requirements. |

| Detailed size | Can be customized according to customer samples or drawings. |

| Standard | JIS, DIN, BS, ASTM, SAE etc. |

| Test Certificate | As per EN 10204 3.1, Third Party Inspection, Buyer Inspection, Mill Test Certificate. |

Features of Solid Aluminum Blocks

- Physical Properties: Aluminum blocks have a low density, making them lightweight and easy to process.

- Mechanical Properties: The strength and hardness of solid aluminum blocks can be optimized through alloying and heat treatment processes.

- They possess good toughness, capable of withstanding certain impact loads.

- Machinability: Solid aluminum blocks are easy to machine and can be cut, drilled, and milled, accommodating various manufacturing needs.

The Main Alloys of HC Solid Aluminum Blocks

HC Aluminum offers a variety of solid aluminum blocks made from different alloys, each with unique properties suited for specific applications.

| Alloy | Type | Characteristics | Applications |

| 2A12 solid aluminum block | Aluminum-Copper alloy | High strength, good machinability, excellent fatigue resistance | Aerospace structures, military applications, high-stress components |

| 1060 solid aluminum block | Aluminum (99.6% min. content) | Excellent corrosion resistance, high thermal and electrical conductivity, good workability | Electrical applications, heat exchangers, chemical handling |

| 2024 solid aluminum block | Aluminum-Copper alloy | High strength, fatigue resistance, lower corrosion resistance | Aerospace applications, military vehicles, high-strength components |

| 3003 solid aluminum block | Aluminum-Manganese alloy | Good corrosion resistance, moderate strength, excellent workability | Cooking utensils, chemical equipment, storage tanks |

| 5005 solid aluminum block | Aluminum-Magnesium alloy | Good corrosion resistance and weldability, slightly lower strength | Architectural applications, decorative applications, signage |

| 5052 solid aluminum block | Aluminum-Magnesium alloy | Excellent corrosion resistance, good weldability, moderate to high strength | Marine environments, automotive fuel tanks, pressure vessels |

| 5083 solid aluminum block | Aluminum-Magnesium alloy | High strength, excellent corrosion resistance, particularly in marine environments | Shipbuilding, pressure vessels, cryogenic tanks |

| 5086 solid aluminum block | Aluminum-Magnesium alloy | Good weldability, moderate to high strength, excellent corrosion resistance | Marine applications, structural components |

| 5182 solid aluminum block | Aluminum-Magnesium alloy | Good weldability, moderate strength | Beverage cans, automotive applications |

| 5454 solid aluminum block | Aluminum-Magnesium alloy | Good corrosion resistance, weldability, moderate strength | Marine structures, pressure vessels, cryogenic applications |

| 5754 solid aluminum block | Aluminum-Magnesium alloy | Good weldability, formability, moderate strength | Automotive body panels, marine applications |

| 6061 solid aluminum block | Aluminum-Magnesium-Silicon alloy | Good mechanical properties, corrosion resistance, weldability | Structural components, automotive parts, aerospace applications |

| 6063 solid aluminum block | Aluminum-Magnesium-Silicon alloy | Good extrudability, surface finish, moderate strength | Architectural applications, window frames, irrigation tubing |

| 6082 solid aluminum block | Aluminum-Magnesium-Silicon alloy | Good corrosion resistance, medium to high strength, good weldability | Structural applications, bridges, cranes |

| 7005 solid aluminum block | Aluminum-Zinc-Magnesium alloy | High strength, good weldability | Bicycle frames, high-strength applications |

| 7075 solid aluminum block | Aluminum-Zinc alloy | Very high strength, lower corrosion resistance, good machinability | Aerospace components, military applications, high-stress components |

Applications of Solid Aluminum Blocks

Mechanical Manufacturing

- Mechanical Parts: Solid aluminum blocks are widely used to manufacture various mechanical components, such as gears, bearing housings, and brackets, due to their excellent machinability and strength.

- Tools and Molds: High-strength aluminum alloy solid blocks are often used to produce various tools and molds, ensuring durability and precision.

Construction Industry

- Structural Components: In construction, solid aluminum blocks are used to create support frames, columns, and beams, providing excellent strength and corrosion resistance.

- Decorative Components: Aluminum blocks can also be processed into architectural decorative materials, such as door and window frames and curtain wall systems, enhancing visual appeal and durability.

Electronics and Electrical

- Heat Sinks: Solid aluminum blocks are commonly used to manufacture heat sinks for electronic devices due to their good thermal conductivity, effectively dissipating heat.

- Casings and Enclosures: In electrical equipment, solid aluminum blocks are used to create casings that protect internal components and provide good electromagnetic interference shielding.

Frequently Asked Questions about Solid Aluminum Blocks

| Question | Answer |

| 1. What is the difference between cast aluminum and solid aluminum? | Cast Aluminum: Cast aluminum is made by melting aluminum and pouring it into a mold to create a specific shape. This process allows for complex geometries but may introduce porosity and inclusions, affecting mechanical properties. It is commonly used for parts requiring complex shapes, such as engine casings and decorative items. Solid Aluminum: Solid aluminum typically refers to aluminum blocks (such as billets, sheets, or rods) manufactured through extrusion or rolling, without the need for casting. It usually has a more uniform grain structure and better mechanical properties, making it widely used for structural applications and machining. |

| 2. How strong is solid aluminum? | The strength of solid aluminum varies depending on the alloy, heat treatment, and processing methods. Factors affecting strength include the alloy composition, heat treatment, and manufacturing methods (such as extrusion, rolling, and forging), all of which can influence the final strength. |