Tin-plated Aluminum Bus Bar

Tin-plated aluminum bus bars are essential components in electrical power distribution systems, offering a combination of aluminum's lightweight and cost-effective properties with the enhanced performance provided by a tin coating.

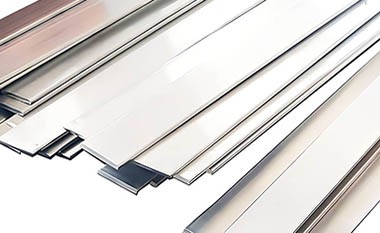

Tin-plated aluminum bus bars are typically made from aluminum alloys such as 1350 or 6061, which are known for their excellent conductivity and mechanical strength. The tin coating is applied through an electroplating process, forming a thin, uniform layer that adheres firmly to the aluminum substrate. This tin layer enhances the bus bar's corrosion resistance and improves its weldability, ensuring reliable electrical connections.

Why Choose Tin-Plated Aluminum?

Uncoated aluminum bus bars are prone to corrosion, which can lead to power supply issues and connection problems. Therefore, HC Aluminum offers tin-plated aluminum bus bars as a durable solution for power distribution.

- Uncoated Aluminum: Suitable for short-term and low-demand electrical applications, but prone to corrosion and connection issues, with poor long-term reliability.

- Tin-Plated Aluminum: Provides higher corrosion resistance, stable conductivity, and better weldability, making it ideal for power transmission and electronic equipment that require high reliability and long-term stability.

Comparison of Tin-Plated Aluminum and Uncoated Aluminum

| Property | Uncoated Aluminum | Tin-Plated Aluminum |

| Corrosion Resistance | Prone to corrosion, especially in humid or polluted environments, where the oxide layer may deteriorate. | The tin layer provides additional protection, effectively preventing oxidation and corrosion. |

| Conductivity | As the oxide layer forms, resistance may increase, affecting power transmission efficiency. | Maintains stable low resistance, ensuring efficient power transmission. |

| Weldability | Difficult to weld, prone to cold welding issues. | Easy to weld, with the tin layer providing good weldability. |

| Thermal Stability | Performance may degrade under high temperatures. | The tin layer enhances the thermal stability of aluminum, preventing oxidation and failure at high temperatures. |

| Galvanic Corrosion Prevention | Prone to galvanic corrosion when in contact with other metals. | The tin layer isolates aluminum from direct contact with other metals, preventing galvanic corrosion. |

| Mechanical Durability | The surface is easily worn and damaged. | The tin layer increases surface hardness, improving wear resistance. |

| Cost | Relatively inexpensive, but maintenance and replacement costs may be higher. | Tin-plating is more expensive, but it extends the service life and reduces maintenance and replacement costs. |

| Common Applications | Power transmission lines, low-load connections. | Electrical bus bars, cable connections, electronic soldering, and high-load power transmission systems. |

Our aluminum bus bars are lightweight and help achieve a balanced distribution of weight in structures. The tin plating prevents oxidation and solves connection reliability issues.

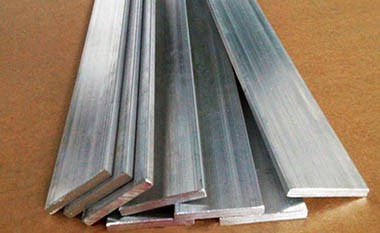

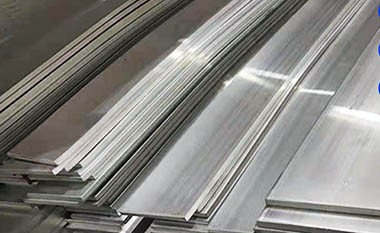

Tin-Plated Aluminum Bus Bar Specifications

| Feature | Description |

| Tin Coating Thickness | 3 to 15 microns (thicker coatings can be deposited upon request) |

| Electroplating Standard | Complies with ASTM B545 electroplating standards |

| Bus Bar Length | Up to 6000 millimeters |

| Bus Bar Width | Up to 200 millimeters |

| Bus Bar Thickness | Up to 40 millimeters |

| Materials | 6061/6063/1350/1100/5052, etc. |

| Maximum Bus Bar Size | Larger bus bars can be manufactured beyond the sizes mentioned above |

| Tolerance Standard | Follows ISO 2768-m general tolerance standards |

HC Aluminum is committed to providing the highest quality tin-plating services for aluminum bus bars and other metal components. We have the most advanced facilities, experienced technicians, and a commitment to customer satisfaction, making us the ultimate solution for all your tin-plating needs.

You can determine the aluminum bus bar size based on current-carrying requirements. Click here to learn about the current-carrying capacity of different aluminum bar sizes.

- Tin Coating Thickness: The thickness of the tin coating can be adjusted according to the application requirements to provide optimal corrosion resistance and conductivity.

- Electroplating Standard: The tin coating is applied in accordance with ASTM B545 standards to ensure uniformity and reliable corrosion resistance.

- Bus Bar Size: Standard sizes are up to 6000 millimeters in length, 200 millimeters in width, and a thickness of up to 40 millimeters, suitable for various power transmission applications. Custom production is available for larger sizes.

- Tolerance Standard: Follows ISO 2768-m standards to ensure consistency and precision in dimensions and tolerances of the aluminum bus bars.

Tin-Plated Aluminum Bus Bar Material Grades

We select aluminum grades based on specifications and final applications. Our preferred choices include:

- Electrical Grade 6061 tin plated aluminum bus bar

- Electrical Grade 6063 tin plated aluminum bus bar

- Electrical Grade 5052 tin plated aluminum bus bar

- Electrical Grade 1100 tin plated aluminum bus bar

- Electrical Grade 1350 tin plated aluminum bus bar

| Material Grade | Description |

| Electrical Grade 6061 Tin-Plated Aluminum Bus Bar | The Electrical Grade 6061 Tin-Plated Aluminum Bus Bar uses 6061 aluminum alloy as the base material, offering good mechanical properties, excellent corrosion resistance, and high strength. This aluminum alloy bus bar is widely used in electrical systems that require high load-bearing capacity and strength, especially in large power transmission and distribution equipment. The tin coating provides additional protection, enhancing corrosion resistance and ensuring long-term stable operation in high-humidity or polluted environments. |

| Electrical Grade 6063 Tin-Plated Aluminum Bus Bar | The Electrical Grade 6063 Tin-Plated Aluminum Bus Bar uses 6063 aluminum alloy, characterized by good extrudability and lower strength. It is suitable for electrical applications that require high conductivity but do not have particularly high strength demands. The tin coating provides excellent oxidation protection while maintaining electrical conductivity, ensuring reliability in high-humidity or corrosive environments. |

| Electrical Grade 5052 Tin-Plated Aluminum Bus Bar | The Electrical Grade 5052 Tin-Plated Aluminum Bus Bar uses 5052 aluminum alloy, which has excellent corrosion resistance, especially in marine or chemical environments. The tin coating further enhances the bus bar's corrosion resistance, making it suitable for power transmission and distribution systems in harsh environments such as ships, oil platforms, etc. The strength of 5052 aluminum alloy is moderate, sufficient for medium-load applications. |

| Electrical Grade 1100 Tin-Plated Aluminum Bus Bar | The Electrical Grade 1100 Tin-Plated Aluminum Bus Bar uses 1100 aluminum alloy, which offers excellent electrical conductivity and good ductility. Due to its high purity, 1100 aluminum alloy has a very low resistance, making it ideal for electrical applications requiring high conductivity. The tin coating not only improves the bus bar's corrosion resistance but also ensures stability in various environments, making it commonly used in medium-to-low power electrical connections and light-load power systems. |

| Electrical Grade 1350 Tin-Plated Aluminum Bus Bar | The Electrical Grade 1350 Tin-Plated Aluminum Bus Bar uses 1350 aluminum alloy, a high-purity aluminum alloy with extremely high conductivity, making it ideal for power transmission applications. The tin coating provides additional protection against oxidation and corrosion, ensuring long-term stability in use. The low resistance and high conductivity of 1350 aluminum alloy make it the perfect choice for high-efficiency power systems, especially for high-power electrical bus systems. |

Surface Treatment of Tin-Plated Aluminum Bus Bars

Direct tin-plating on aluminum bus bars can lead to adhesion issues and electrochemical corrosion. Therefore, we introduce an intermediate zinc immersion step to address this problem.

We perform surface treatment on the aluminum bus bars and then immerse them in a zinc bath. After the zinc dries on the bus bar, we proceed with the tin-plating process. We use either immersion tin-plating or electroplating techniques for tin-plating the aluminum bus bars.

Advantages of Tin-Plated Aluminum Bus Bars

- Corrosion Resistance: The tin coating provides a protective barrier against environmental factors, reducing the risk of oxidation and extending the lifespan of the bus bars.

- Solderability: The tin-plated surface makes welding easier and more reliable, which is essential for creating safe electrical joints.

- Conductivity: While aluminum itself has good electrical conductivity, the tin coating can enhance performance, especially in applications that require superior conductivity.

- Lightweight: Our tin-plated aluminum bus bars are lightweight, making them suitable for installation in confined spaces.

- Efficient Heat Dissipation: Tin-plated aluminum bus bars have good thermal exchange properties, reducing thermal load.

- Excellent Weldability: Tin-plated aluminum bars easily establish weldable connections.

- Aesthetics: Tin-plated aluminum bus bars have a shiny, uniform appearance, making them the preferred choice for visible installations, contributing to a clean, professional look.

- Durability: Tin-plating enhances the durability of aluminum bus bars. The tin layer acts as a barrier, protecting the underlying aluminum from wear and extending the bus bar's lifespan.

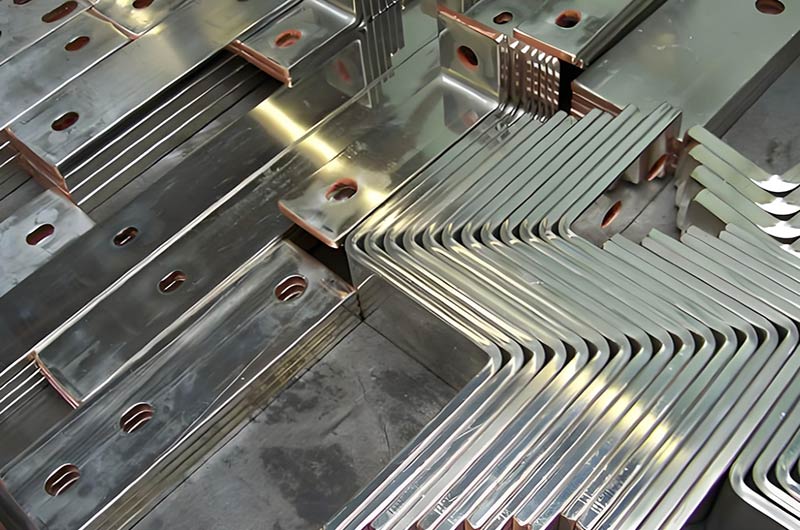

Applications of Tin-Plated Aluminum Bus Bars

Tin-plated aluminum bus bars are widely used across various industries, including:

- Power Generation: Used as conductors in power plants and substations.

- Telecommunications: Provides reliable electrical connections in communication equipment.

- Electric Vehicles: Used in battery management systems and distribution devices.

- Transportation: Used in power distribution for railways and ships.

| Industry | Application Description |

| Power Generation | Tin-plated aluminum bus bars are widely used in power plants and substations as conductors for power transmission and distribution. Due to their low resistance and excellent conductivity, tin-plated aluminum bus bars can effectively transfer electricity from generators or transformers to the distribution system. The tin coating provides corrosion protection, ensuring the bus bar maintains stable performance in high humidity, polluted, or harsh environments. The antioxidant properties of the tin layer significantly extend the bus bar's lifespan and reduce maintenance requirements. |

| Telecommunications | Tin-plated aluminum bus bars are used in the telecommunications industry to provide reliable electrical connections, ensuring the stable operation of communication equipment. As the complexity and power demands of communication equipment increase, tin-plated aluminum bus bars become the ideal choice because they not only offer good conductivity but can also resist corrosion from external environments. The tin layer enhances the durability of the aluminum bus bar, enabling it to maintain low resistance and high efficiency in high humidity and long-term use, ensuring the stability and efficiency of communication systems. |

| Electric Vehicles | Tin-plated aluminum bus bars are used in electric vehicles for battery management systems and power distribution devices. These bus bars can transmit power between the battery pack and the power system, ensuring efficient and stable power distribution. The protective tin layer allows the bus bar to function in high-temperature and high-humidity environments for extended periods while resisting corrosion, enhancing the overall reliability of the electric vehicle system. In addition, the lightweight and good conductivity of tin-plated aluminum bus bars make them highly suitable for power systems in electric vehicles that require high efficiency and weight reduction. |

| Transportation | Tin-plated aluminum bus bars are also widely used in railway and ship power distribution systems. As the transportation industry requires efficient and durable power transmission systems, tin-plated aluminum bus bars become an ideal choice. They can provide reliable power transmission in railway vehicle power distribution systems, while maintaining stable operation in the electrical systems of ships. The tin coating provides additional corrosion protection, allowing the aluminum bus bars to maintain long-term performance stability in harsh transportation environments, especially those exposed to humidity and seawater corrosion. |

Precautions

While tin-plated aluminum bus bars offer many advantages, it is important to note that tin is softer and has higher resistance compared to silver. Therefore, for applications requiring the highest conductivity and durability, silver plating may be the preferred choice.

Tin-plated aluminum bus bars provide an economical and efficient solution for power distribution, combining the inherent advantages of aluminum with the protective and performance-enhancing features of tin plating.