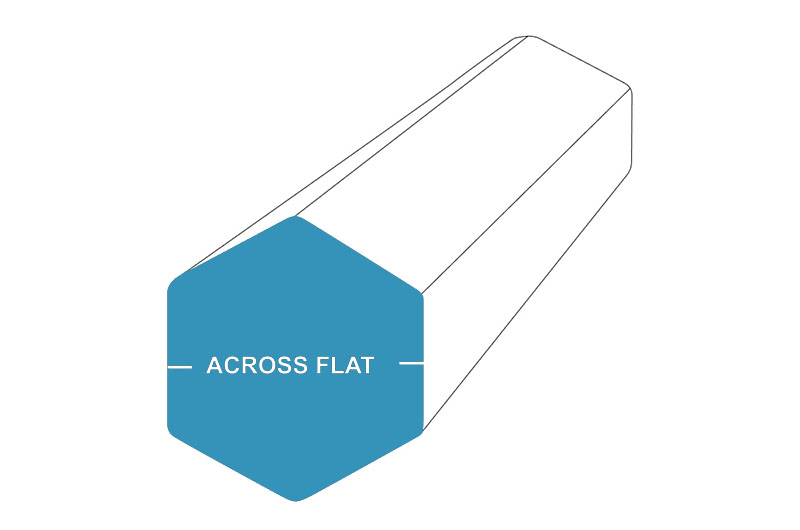

0.5" 6061-T6511 Aluminum Hexagonal Bar Extruded

This 6061-T6511 aluminum hexagonal bar has an across flats dimension of 0.5 inches, processed by extrusion and heat-treated to T6511. It provides high strength and excellent corrosion resistance, commonly used in structural components, frames, and supports that bear heavy loads.

This material meets the following specs: AMS-QQ-A-200/8, ASTM-B221

0.5" 6061-T6511 Aluminum Hexagonal Bar Extruded Specifications

| Specification | Details |

| Across Flats | 0.5" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 6061 |

| Max Length | 144 inches (12 feet) |

| Temper | T6511 |

| Production Method | Extruded |

0.5" (Across Flats) 6061-T6511 Aluminum Hexagonal Bar Extruded More Informations

Properties: The T6511 temper, which includes additional stretching, enhances the stability of the material, providing improved corrosion resistance and excellent toughness.

Applications: Suitable for aerospace structural components, transportation vehicle frames, machinery parts, light industrial equipment, and structural components that require high strength and corrosion resistance.

Processing Method: Manufactured using the extrusion process, this hexagonal bar ensures consistent dimensions, making it ideal for complex shape fabrication and machining.

6061 aluminum alloy hexagonal bar is widely used in aviation, automobile, shipbuilding, machinery manufacturing and other fields due to its excellent strength, corrosion resistance and weldability. Different sizes and processing states (such as T6, T6511, cold processing) enable each product to adapt to different industrial needs and processing methods.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- Custom cuts supported

6061 T6511 Aluminum Mechanical Properties

| Property | Value |

| Ultimate Tensile Strength KSI | 42 |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 40 |

| Brinell Hardness 500 kg load | 93 |

| Melting Point °F | 1080 - 1205 |

| Elongation % in 2 in. | 9 |

| Rockwell Hardness B Scale | 59 |

| Machinability % | 50 |

| Shear Strength KSI | 25 |

| Electrical Conductivity % IACS | 43 |

Chemistry Information 6061 Aluminum

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |