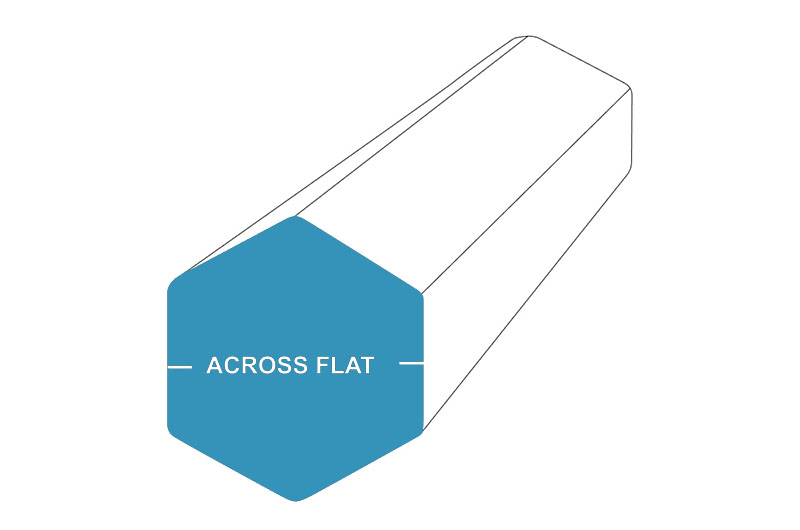

0.75" Aluminum Hexagonal Bar 6262-T6511-Extruded

The 0.75" Aluminum Hexagonal Bar 6262-T6511-Extruded refers to an extruded hexagonal bar with a 0.75-inch measurement across the flats, meaning the distance between two opposite parallel sides of the hexagon. This bar is made from 6262-T6511 aluminum, which has undergone solution heat treatment, stress-relieving, and artificial aging to improve its strength, toughness, and durability. The extruded processing method ensures precise dimensional control and smooth surface quality, making it ideal for applications requiring moderate strength, good machinability, and excellent corrosion resistance. It's typically used in light structural components, aerospace parts, and mechanical assemblies.

0.75" Aluminum Hexagonal Bar 6262-T6511-Extruded Specifications

| Specification | Details |

| Across Flats | 0.75" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 6262 |

| Max Length | 144 inches (12 feet) |

| Temper | T6511 |

| Production Method | Extruded |

0.75" Aluminum Hexagonal Bar 6262-T6511-Extruded More Informations

Specification: 0.75 inches (Across Flats)

Features:

- Strength: Medium to high strength, suitable for light to moderate load-bearing applications.

- Corrosion Resistance: Excellent resistance to corrosion, ideal for outdoor or mildly chemical environments.

- Machinability: Easy to cut, turn, mill, and machine with excellent surface finish and precision.

- Surface Treatment: Extruded hexagonal bar with smooth surface, suitable for anodizing to improve hardness and wear resistance.

Applications:

- Precision Mechanical Parts: Used in machinery manufacturing, automation equipment, and various lightweight structural components.

- Electronic Devices: Suitable for manufacturing electronic enclosures, brackets, and mounting parts.

- Aerospace: Used for auxiliary structures and support components in aerospace applications, suitable for moderate pressure-bearing needs.

Processing Method: Extruded – ensures uniform density, strength, and surface quality, suitable for quick production of large quantities of high-precision parts.

6262 aluminum alloy is an alloy used primarily for lightweight structures and high-strength applications, particularly in environments requiring good processability and high corrosion resistance. The T6511 temper is obtained by solution heat treatment, stress relief treatment and artificial aging, which gives it high strength and good ductility. Compared to the T6510 temper, the straightening of T6511 is guaranteed, making it more reliable in certain demanding applications.

6262-T6511 aluminum alloy hexagonal bars have good strength, corrosion resistance and surface quality after extrusion. The T6511 temper ensures high strength and good fatigue resistance, while the extrusion process ensures consistency and precision of products of various specifications. They have a wide range of applications in aerospace, automotive, construction and precision machinery, especially for structural parts that require high strength, light weight and precision machining.

6262-T6511 aluminum alloy hexagonal bars can also be cold worked, providing a high surface finish and precision, making them widely used in aerospace, construction, machinery manufacturing and other precision industries. The T6511 state provides excellent strength and corrosion resistance, suitable for a variety of harsh environments, especially applications requiring high strength and lightweight.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- Custom cuts supported

6262 T6511 Aluminum Mechanical Material Data Sheet

| Property | Value |

| Density | 0.098 lb/in3 |

| Ultimate Tensile Strength | 43 ksi |

| Yield Tensile Strength | 39 ksi |

| Fatigue Strength | 15 ksi |

| Shear Strength | 26 ksi |

| Shear Modulus | 3, 700 ksi |

| Hardness Rockwell | Brinell | B36 | 71 |

| Elongation at Break Percentage | 10% |

| Modulus of Elasticity | 9, 900 ksi |

| Poisson's Ratio | 0.33 |

| Machinability Percentage | 70% |

| Melting Point | 1, 080-1, 205 °F |

| Specific Heat | 2.1 x 10^-1 BTU/lb-°F |

| Thermal Conductivity | 1, 188 BTU-in/hr-ft^2-°F |

| Electrical Conductivity | 44% IACS |

Chemistry Information 6262 Aluminum

| Element | Percentage |

| Al | 94.6 - 97.8 |

| Bi | 0.4 - 0.7 |

| Cr | 0.04 - 0.14 |

| Cu | 0.15 - 0.4 |

| Fe | 0.7 max |

| Pb | 0.4 - 0.7 |

| Mg | 0.8 - 1.2 |

| Mn | 0.15 max |

| Si | 0.4 - 0.8 |

| Ti | 0.15 max |

| Zn | 0.25 max |