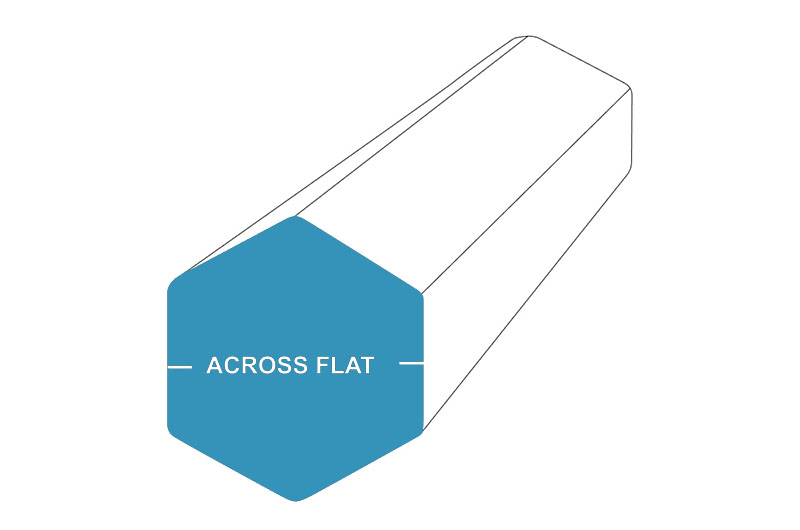

0.75" Aluminum Hexagonal Bar 7075-T7351-Cold Finish

This 0.75" (Across Flats) hexagonal bar in 7075-T7351 aluminum features exceptional strength-to-weight ratio, corrosion resistance, and high durability. Cold finishing improves dimensional accuracy, making it a reliable choice for aerospace, automotive, and high-performance equipment manufacturing.

This material meets the following specs: ASTM-B211, AMS-QQ-A-225/9

0.75" Aluminum Hexagonal Bar 7075-T7351-Cold Finish Specifications

| Specification | Details |

| Across Flats | 0.75" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 7075 |

| Max Length | 300 inches |

| Temper | T7351 |

| Production Method | Cold Finished |

0.75" Aluminum Hexagonal Bar 7075-T7351-Cold Finish More Informations

Features:

Size: 0.75 inches Across Flats

Outstanding strength, rigidity, and corrosion resistance, suitable for extreme environments.

Cold finish ensures high precision and smooth surface suitable for further machining.

Applications:

Used in aerospace for structural components such as wing frames, landing gear parts, and high-strength structural parts.

Military and automotive applications requiring high strength and durability in harsh conditions.

Processing:

Cold finishing ensures excellent surface finish, providing a high degree of precision for further machining and assembly.

7075 aluminum alloy is highly popular in high-strength applications such as aerospace, military, and automotive industries, especially in the T7351 temper, which offers exceptional mechanical properties and corrosion resistance.

7075-T7351 cold finished aluminum hex bars are made from 7075 aluminum alloy and undergo T7351 heat treatment, providing extremely high strength and excellent corrosion resistance. These aluminum hex bars are widely used in industries such as aerospace, military, and automotive, where high strength and lightweight materials are essential.

7075-T7351 cold finished aluminum hex bars, available in various sizes, offer extremely high strength, good corrosion resistance, and outstanding mechanical properties. The cold finishing process ensures a smooth surface and high dimensional accuracy, making them ideal for applications that require high strength and durability, such as aerospace, military, and high-performance automotive sectors.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- 300" (25 ft.)

- Custom cuts supported

7075 T7351 Aluminum Material Data Sheet

| Property | Value |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 63 |

| Ultimate Tensile Strength KSI | 73 |

| Brinell Hardness 500 kg load | 135 |

| Rockwell Hardness B Scale | 82 |

| Elongation % in 2 in. | 8 |

| Melting Point °F | 890 - 1180 |

| Shear Strength KSI | 44 |

| Machinability % | 70 |

| Electrical Conductivity % IACS | 33 |

Chemistry Information 7075 Aluminum

| Element | Percentage |

| Al | 90 |

| Cr | 0.18 - 0.28 |

| Cu | 1.2 - 2 |

| Fe | 0.5 max |

| Mg | 2.1 - 2.9 |

| Mn | 0.3 max |

| Si | 0.4 max |

| Ti | 0.2 max |

| Zn | 5.1 - 6.1 |

| Zr+Ti | 0.25 max |