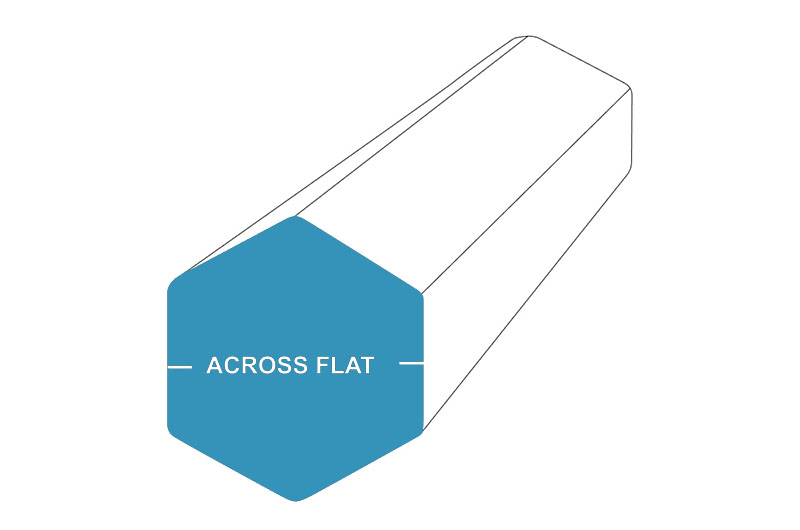

0.875" Aluminum Hexagonal Bar 2011-T3-Cold Finish

This 0.875-inch aluminum hexagonal bar is made from 2011-T3 aluminum alloy, with a cold finish providing excellent surface smoothness and precision. The "Across Flats" length is 0.875 inches, making it ideal for larger, higher-strength structural components, widely used in aerospace, automotive, and heavy machinery industries.

0.875" Aluminum Hexagonal Bar 2011-T3-Cold Finish Specifications

| Specification | Details |

| Across Flats | 0.875" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 2011 |

| Max Length | 300 inches |

| Temper | T3 |

| Production Method | Cold Finished |

0.875" Aluminum Hexagonal Bar 2011-T3-Cold Finish More Informations

Features: The 0.875" hexagonal bar is larger, offering improved durability and strength, while maintaining the easy machinability of 2011-T3 aluminum. The cold finish process results in a smooth, accurate surface suitable for detailed machining.

Applications: Ideal for use in structural components, brackets, and other parts requiring high strength and resistance to wear, common in automotive, aerospace, and heavy machinery applications.

Cold Finish Processing: Cold finishing improves dimensional accuracy and surface quality, making it a ready-to-machine component with consistent properties for specialized applications.

2011-T3 Cold Finished Aluminum Hex Bar is available in a variety of sizes and is designed for high-precision machined parts that require strength and excellent machining properties. The T3 temper ensures that the aluminum is strengthened, while cold working improves its dimensional accuracy and smooth surface, making it ideal for industries such as aerospace, automotive, and precision machinery.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- 300" (25 ft.)

- Custom cuts supported

2011 T3 Aluminum Material Data Sheet

| Property | Value |

| Density | 0.102 lb/in³ |

| Hardness (Brinell) | 95 |

| Tensile Strength | 55, 000 psi |

| Tensile Yield Strength | 43, 000 psi |

| Elongation at Break | 15% |

| Modulus of Elasticity | 10, 200 ksi |

| Poisson's Ratio | 0.33 |

| Fatigue Strength | 18, 000 psi |

| Shear Modulus | 3, 770 ksi |

| Shear Strength | 32, 000 psi |

| Melting Point | 1005 - 1190 °F |

| Annealing Temperature | 775 °F |

| Solution Temperature | 975 °F |

Chemistry Information 2011 Aluminum

| 2011 Alloy % | |

| Si | 0.40-0.80 |

| Fe | 0.70 |

| Cu | 5.0-6.0 |

| Mn | - |

| Mg | - |

| Zn | 0.30 |

| Bi | 0.20-0.60 |

| Pb | 0.20-0.60 |

| Al | Remainder |