1.5" x 1.5" x 0.125" Aluminum T-Bar 6063-T52-Extruded

This 6063 aluminum alloy T-bar has dimensions of 1.5 inches x 1.5 inches x 0.125 inches, making it suitable for applications requiring moderate strength and a larger surface area. The extrusion process ensures the shape's stability and precision. The material’s corrosion resistance and good surface processability make it widely used in architectural decoration and light structural components, especially for frame and support applications.

This material meets the following specs: ASTM-B221

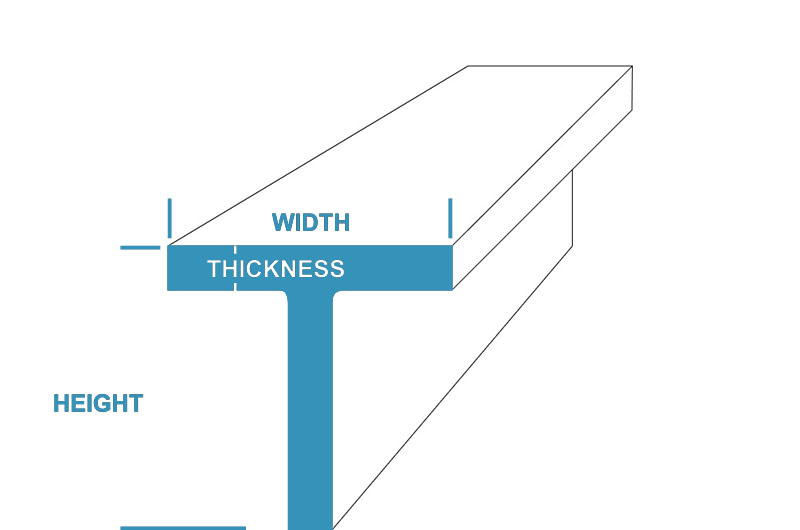

1.5" x 1.5" x 0.125" Aluminum T-Bar 6063-T52-Extruded Specifications

| Specification | Details |

| Height | 1.5" |

| Thickness | 0.125" |

| Width | 1.5" |

| Material | Aluminum |

| Form | t bar |

| Alloy Type | 6063 |

| Max Length | 288 inches (24 feet) |

| Temper | T52 |

| Production Method | Extruded |

1.5" x 1.5" x 0.125" Aluminum T-Bar 6063-T52-Extruded More Informations

Properties: The 1.5-inch T-bar has better bending performance and rigidity, while maintaining the light weight of 6063-T52 aluminum alloy. It also offers excellent corrosion resistance and weathering properties, making it suitable for long-term outdoor exposure.

Applications: Commonly used in structural supports, display racks, lightweight frames, building exterior decorations, and mechanical and electrical equipment supports. It is also suitable for precision assembly structures, ensuring the overall stability of products.

Processing: This T-bar can be cold-worked, drilled, and precisely cut. It is ideal for anodizing to improve surface corrosion resistance and durability.

6063-T52 aluminum alloy is a common medium-strength aluminum alloy with excellent extrudability and surface treatment properties, and is usually used to manufacture lightweight structural parts. After artificial aging treatment, 6063-T52 aluminum has good strength, corrosion resistance and high weldability.

The common characteristics of T-shaped bars are good machinability, excellent corrosion resistance and lightness. They are mainly used in fields that require structural strength but have requirements for weight, such as construction, electronic equipment, mechanical frames, door and window decoration, vehicle brackets, etc. After extrusion molding, these products can be processed secondary according to demand, such as anodizing, spraying, cutting, etc., to achieve higher aesthetics and durability.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- Custom cuts supported

6063 T52 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Ultimate Tensile Strength KSI | 27 |

| Yield Tensile Strength KSI | 21 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 17 |

| Melting Point °F | 1140 - 1210 |

| Brinell Hardness 500 kg load | 60 |

| Shear Strength KSI | 15 |

Chemistry Information 6063 Aluminum

| Element | Percentage |

| Al | 98.9 |

| Cr | 0.1 max |

| Cu | 0.1 max |

| Mg | 0.45 - 0.9 |

| Fe | 0.35 max |

| Mn | 0.1 max |

| Si | 0.2 - 0.6 |

| Zn | 0.1 max |

| Ti | 0.1 max |