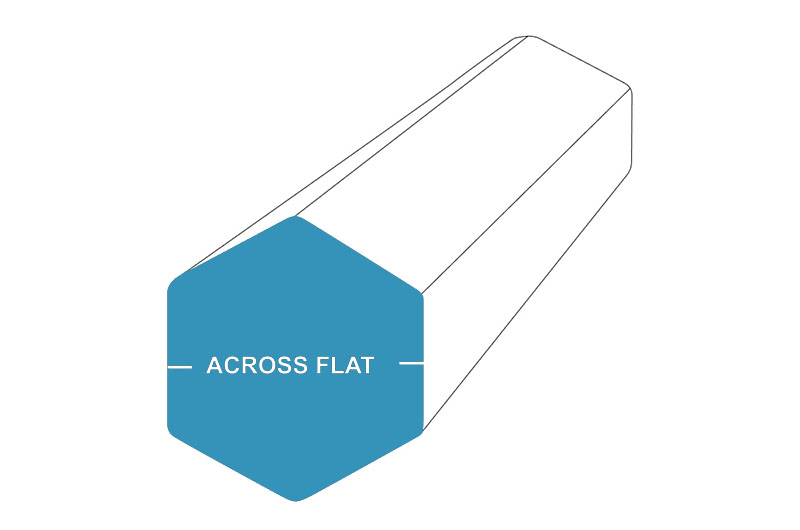

1.5625" Aluminum Hexagonal Bar 2024-T851-Cold Finish

With an across-flats measurement of 1.5625 inches, this 2024-T851 aluminum hex bar is cold-finished for tight tolerances and excellent surface quality. It is commonly used in demanding applications such as aerospace structural components, industrial machinery, and automotive parts due to its exceptional mechanical properties.

1.5625" Aluminum Hexagonal Bar 2024-T851-Cold Finish Specifications

| Specification | Details |

| Across Flats | 1.5625" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 2024 |

| Max Length | 288 inches (24 feet) |

| Temper | T851 |

| Production Method | Cold Finished |

1.5625" Aluminum Hexagonal Bar 2024-T851-Cold Finish More Informations

Material: 2024-T851 aluminum, offering superior performance in high-stress and high-fatigue environments.

Characteristics: After processing, the material provides excellent strength, fatigue resistance, and stress corrosion resistance.

Applications: Ideal for the manufacturing of large aerospace structural components, including ribs, bulkheads, and high-performance components in military aviation.

Processing Method: Cold finish, maintaining surface integrity and precision for further machining or direct application.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- Custom cuts supported

2024 T851 Aluminum Material Data Sheet

| Physical Properties | Metric | English | Comments |

| Density | 2.78 g/cc | 0.1 lb/in³ | AA; Typical |

| 2024 T851 Aluminum Mechanical Properties | |||

| Hardness, Brinell | 128 | 128 | 500 kg load/10 mm ball |

| Hardness, Knoop | 161 | 161 | Estimated from Brinell |

| Hardness, Rockwell A | 49 | 49 | Estimated from Brinell |

| Hardness, Rockwell B | 79 | 79 | Estimated from Brinell |

| Hardness, Vickers | 146 | 146 | Estimated from Brinell |

| Tensile Strength, Ultimate | Min 455 MPa | Min 66000 psi | |

| Tensile Strength, Yield | Min 400 MPa | Min 58000 psi | |

| Elongation at Break | 5 % | 5 % | |

| Modulus of Elasticity | 72.4 GPa | 10500 ksi | Estimated from other heat treatments. |

| Poisson's Ratio | 0.33 | 0.33 | Estimated from other heat treatments. |

| Fatigue Strength | 117 MPa | 17000 psi | 500, 000, 000 cycles; completely reversed; R. R. Moore Machine and specimen. |

| Machinability | 70 % | 70 % | 0-100 Scale (A=90; B=70; C=50; D=30; E=10) |

| Shear Modulus | 27 GPa | 3920 ksi | Estimated from similar Al alloys. |

| Shear Strength | 296 MPa | 42900 psi | |

| 2024 T851 Aluminum Electrical Properties | |||

| Electrical Resistivity | 4.5e-006 ohm-cm | 4.5e-006 ohm-cm | |

| 2024 T851 Aluminum Thermal Properties | |||

| CTE, linear 68°F | 23.2 µm/m-°C | 12.9 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 24.7 µm/m-°C | 13.7 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.875 J/g-°C | 0.209 BTU/lb-°F | |

| Thermal Conductivity | 151 W/m-K | 1050 BTU-in/hr-ft²-°F | |

| Melting Point | 502 - 638 °C | 935 - 1180 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization. |

| Solidus | 502 °C | 935 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

| 2024 T851 Aluminum Processing Properties | |||

| Annealing Temperature | 413 °C | 775 °F | |

| Solution Temperature | 256 °C | 493 °F | |

Chemistry Information 2024 Aluminum

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.90 | 1.20-1.80 | 0.10 | 0.25 | - | 0.15 | GB/AMS/EN |