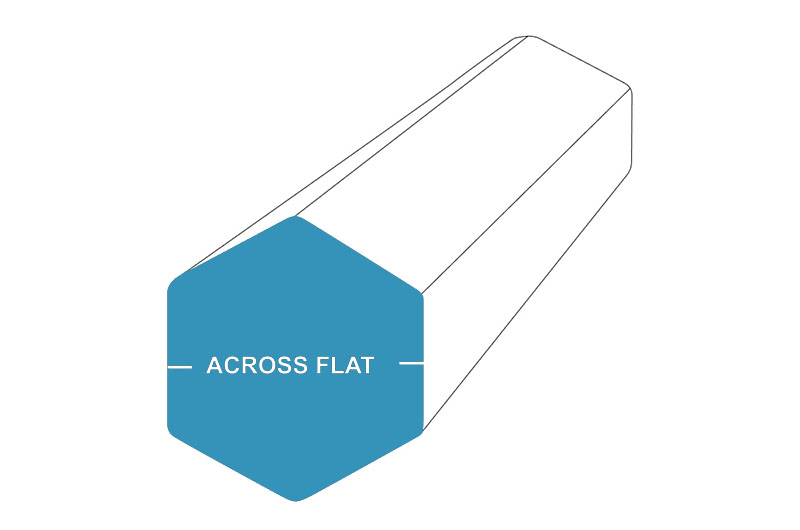

1.6875" Aluminum Hexagonal Bar 2024-T351-Cold Finish

The 1.6875" hexagonal bar is crafted from 2024-T351 aluminum, offering exceptional mechanical properties such as high strength and fatigue resistance. The 1.6875" measurement refers to the across flats dimension of the hexagonal bar. Cold finishing ensures a smooth, consistent surface, ideal for aerospace and structural components requiring high performance and accuracy.

1.6875" Aluminum Hexagonal Bar 2024-T351-Cold Finish Specifications

| Specification | Details |

| Across Flats | 1.6875" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 2024 |

| Max Length | 300 inches |

| Temper | T351 |

| Production Method | Cold Finished |

1.6875" Aluminum Hexagonal Bar 2024-T351-Cold Finish More Informations

Properties: This aluminum bar offers excellent corrosion resistance and high strength. The T351 condition guarantees that it maintains strong structural performance under demanding load conditions.

Applications: Suitable for high-load aerospace components, such as aircraft frames, landing gear structures, and support beams.

Processing Method: Cold finishing increases surface hardness and wear resistance, ensuring the bar is ideal for high-strength, high-precision industrial applications.

2024-T351 aluminum alloy hexagonal bar has excellent tensile strength, fatigue resistance and good machinability, suitable for aerospace, high load and high precision applications. The cold working process can ensure the high precision and surface quality of the product, making it suitable for various aviation and industrial environments.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- 300" (25 ft.)

- Custom cuts supported

2024 T351 Aluminum Material Data Sheet

| Physical Properties | Metric | English | Comments |

| Density | 2.78 g/cc | 0.1 lb/in³ | AA; Typical |

| Mechanical Properties | |||

| Hardness, Brinell | 120 | 120 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 150 | 150 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 46.8 | 46.8 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 75 | 75 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 137 | 137 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 469 MPa | 68000 psi | AA; Typical |

| Tensile Yield Strength | 324 MPa | 47000 psi | AA; Typical |

| Elongation at Break | 19 % | 19 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Elongation at Break | 20 % | 20 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Modulus of Elasticity | 73.1 GPa | 10600 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Ultimate Bearing Strength | 814 MPa | 118000 psi | Edge distance/pin diameter = 2.0 |

| Bearing Yield Strength | 441 MPa | 64000 psi | Edge distance/pin diameter = 2.0 |

| Poisson's Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 138 MPa | 20000 psi | AA; 500, 000, 000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 26 MPa-m½ | 23.7 ksi-in½ | K(IC) in S-L Direction |

| Fracture Toughness | 32 MPa-m½ | 29.1 ksi-in½ | K(IC) in T-L Direction |

| Fracture Toughness | 37 MPa-m½ | 33.7 ksi-in½ | K(IC) in L-T Direction |

| Machinability | 70 % | 70 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 28 GPa | 4060 ksi | |

| Shear Strength | 283 MPa | 41000 psi | AA; Typical |

| Electrical Properties | |||

| Electrical Resistivity | 5.82e-006 ohm-cm | 5.82e-006 ohm-cm | AA; Typical at 68°F |

| Thermal Properties | |||

| CTE, linear 68°F | 23.2 µm/m-°C | 12.9 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 24.7 µm/m-°C | 13.7 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.875 J/g-°C | 0.209 BTU/lb-°F | |

| Thermal Conductivity | 121 W/m-K | 840 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 502 - 638 °C | 935 - 1180 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization. |

| Solidus | 502 °C | 935 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

| Processing Properties | |||

| Annealing Temperature | 413 °C | 775 °F | |

| Solution Temperature | 256 °C | 493 °F | |

Chemistry Information 2024 Aluminum

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.90 | 1.20-1.80 | 0.10 | 0.25 | - | 0.15 | GB/AMS/EN |