2" x 2" x 0.25" Aluminum T-Bar 6061-T6-Extruded

The 2" x 2" x 0.25" Aluminum T-Bar is also extruded from 6061-T6 aluminum, a versatile material that offers an excellent combination of strength, corrosion resistance, and formability. The extrusion process allows for precise shaping, followed by heat treatment to the T6 temper, optimizing the material for structural use. This T-bar is well-suited for applications requiring greater strength and stability, such as framing, bracing, or as a support structure in both industrial and architectural projects. Its 0.25" thickness ensures it is sturdy enough for demanding applications without being overly heavy.

This material meets the following specs: AMS-QQ-A-200/8, ASTM-B221, ASTM-B308

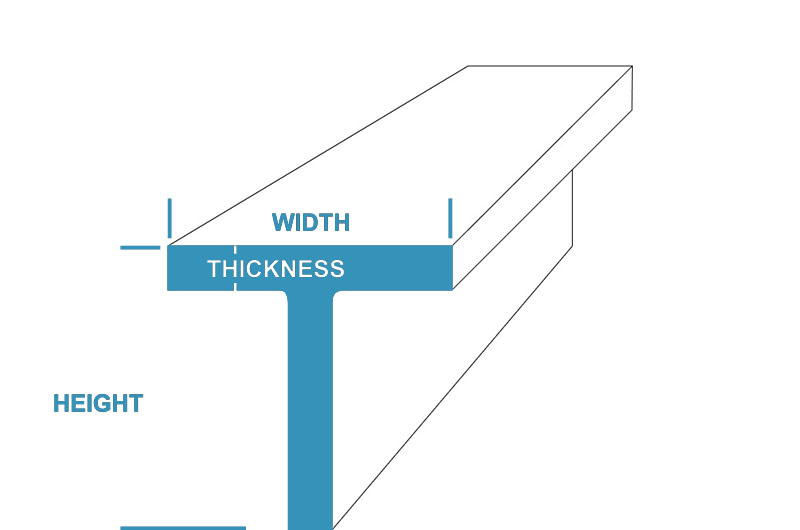

2" x 2" x 0.25" Aluminum T-Bar 6061-T6-Extruded Specifications

| Specification | Details |

| Height | 2" |

| Thickness | 0.25" |

| Width | 2" |

| Material | Aluminum |

| Form | t bar |

| Alloy Type | 6061 |

| Max Length | 300 inches |

| Temper | T6 |

| Production Method | Extruded |

2" x 2" x 0.25" Aluminum T-Bar 6061-T6-Extruded More Informations

Characteristics:

- Strength and Rigidity: Compared to smaller T-bars, this size offers increased bending strength and is suitable for higher load-bearing applications.

- Corrosion Resistance: It features strong oxidation resistance and corrosion resistance, suitable for marine, industrial, and outdoor environments.

- Weldability and Formability: Excellent weldability and machinability, even for larger-sized T-bars.

Applications:

- Aerospace: Used in larger aircraft frame and structural components.

- Construction: Suitable for building structural components or support frames exposed to outdoor environments.

- Automotive and Transport: Ideal for support structures in trucks, trailers, and transportation equipment.

- Manufacturing: Widely used in machinery stands, process frames, and assembly parts.

Processing:

- Extrusion Process: Precision extrusion ensures that this size of T-bar meets exact dimensional and surface quality requirements.

- Heat Treatment (T6): Heat treated to T6 state through solution heat treatment and artificial aging, providing high strength.

Different sizes of 6061-T6 aluminum T-bars are widely used in aviation, automotive, industrial, construction and other fields due to their superior mechanical properties, good weldability, excellent corrosion resistance and high strength. T-bars of different sizes are suitable for various needs from light structures to heavy load-bearing applications, and all of these products are heat treated to achieve higher strength, enabling them to withstand higher loads. In terms of processing, 6061-T6 aluminum has good operability in extrusion and subsequent processing, which is convenient for meeting various customized needs.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- 300" (25 ft.)

- Custom cuts supported

6061 T6 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 40 |

| Brinell Hardness 500 kg load | 95 |

| Ultimate Tensile Strength KSI | 45 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 60 |

| Machinability % | 50 |

| Melting Point °F | 1080 - 1205 |

| Electrical Conductivity % IACS | 43 |

| Shear Strength KSI | 30 |

Chemistry Information 6061 Aluminum

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |