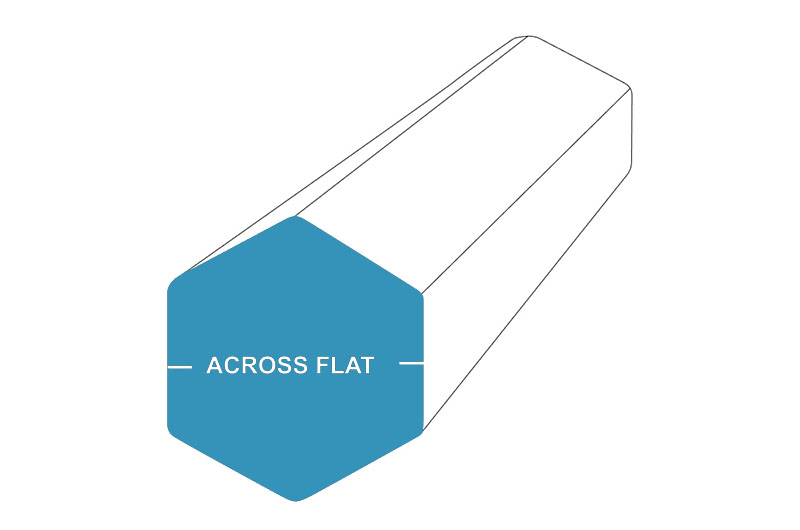

2" Aluminum Hexagonal Bar 6061-T651-Extruded

The 2" Across Flats 6061-T651 aluminum hexagonal bar is extruded, providing excellent strength-to-weight properties and consistent mechanical characteristics. It is ideal for large-scale structural components, such as frames, beams, and supports, in aerospace, automotive, and manufacturing industries that require both high strength and light weight.

2" Aluminum Hexagonal Bar 6061-T651-Extruded Specifications

| Specification | Details |

| Across Flats | 2" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 6061 |

| Max Length | 288 inches (24 feet) |

| Temper | T651 |

| Production Method | Extruded |

2" Aluminum Hexagonal Bar 6061-T651-Extruded More Informations

Specifications: 2" (Across Flats)

Material: 6061-T651

Processing Method: Extruded

Properties:

- Larger cross-section offers robust load-bearing capacity and rigidity.

- The extrusion process ensures high surface quality and precise dimensional control.

Applications:

Widely used in mechanical supports, structural frames, aerospace, and automotive industries.

6061 aluminum alloy hexagonal bar is widely used in aviation, automobile, shipbuilding, machinery manufacturing and other fields due to its excellent strength, corrosion resistance and weldability. Different sizes and processing states (such as T6, T6511, cold processing) enable each product to adapt to different industrial needs and processing methods.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- Custom cuts supported

6061 T651 Aluminum Mechanical Properties

| Property | Value |

| Ultimate Tensile Strength KSI | 46 |

| Yield Tensile Strength KSI | 39 |

| Density g/cm^3 | 3 |

| Brinell Hardness 500 kg load | 93 |

| Rockwell Hardness B Scale | 59 |

| Elongation % in 2 in. | 11 |

| Shear Strength KSI | 30 |

| Melting Point °F | 1080 - 1205 |

| Machinability % | 50 |

| Electrical Conductivity % IACS | 43 |

Chemistry Information 6061 Aluminum

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |