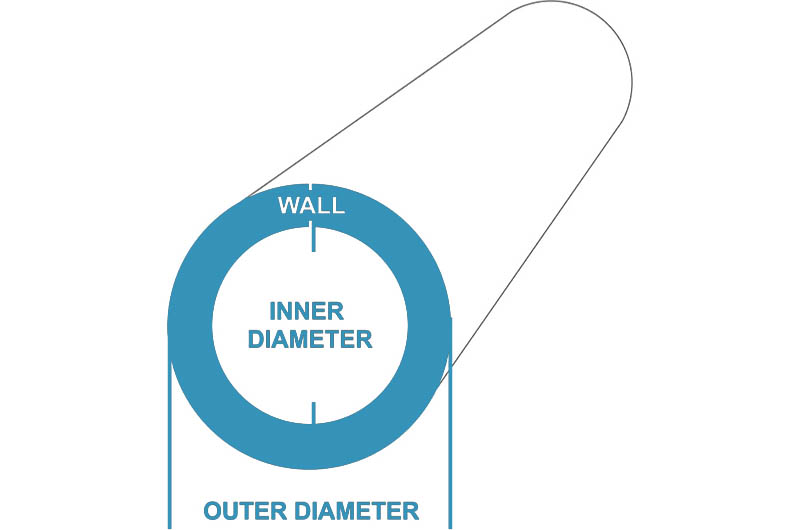

3.5" OD x 0.125" Wall x 3.25" ID Aluminum Round Tube 6063-T52-Extruded

This 6063-T52 aluminum round tube has an outer diameter of 3.5 inches, a wall thickness of 0.125 inches, and an inner diameter of 3.25 inches, making it suitable for lightweight structural components, particularly in building and industrial applications, such as frames, brackets, and conduits.

Outer Diameter (OD): 3.5 inches (88.9 mm)

Wall Thickness: 0.125 inch (3.18 mm)

Inner Diameter (ID): 3.25 inches (82.55 mm)

Material: 6063-T52 extruded aluminum

Properties: Offers moderate strength and excellent corrosion resistance, making it versatile for various industrial and architectural uses.

Applications: Ideal for use in medium-sized structural supports, handrails, and custom frameworks.

This material meets the following specs: ASTM -B221

The extrusion process used in the production of aluminum alloy round tubes can ensure its smooth surface and precise size, while retaining the excellent physical properties of 6063-T52 aluminum alloy, such as good corrosion resistance, moderate strength and good processing performance.

3.5" OD x 0.125" Wall x 3.25" ID Aluminum Round Tube 6063-T52-Extruded Specifications

| Specification | Details |

| OD | 3.5" |

| Wall Thickness | 0.125" |

| ID | 3.25" |

| Material | Aluminum |

| Form | round tube |

| Alloy Type | 6063 |

| Max Length | 288 inches (24 feet) |

| Temper | T52 |

| Production Method | Extruded |

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- Custom cuts supported

6063 T52 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Ultimate Tensile Strength KSI | 27 |

| Yield Tensile Strength KSI | 21 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 17 |

| Melting Point °F | 1140 - 1210 |

| Brinell Hardness 500 kg load | 60 |

| Shear Strength KSI | 15 |

Chemistry Information 6063 Aluminum

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other (each) | Other (total) | Al |

| Composition (%) | 0.20 – 0.60 | 0.35 max | 0.10 max | 0.10 max | 0.45 – 0.90 | 0.10 max | 0.10 max | 0.10 max | 0.05 max | 0.15 max | Balance |