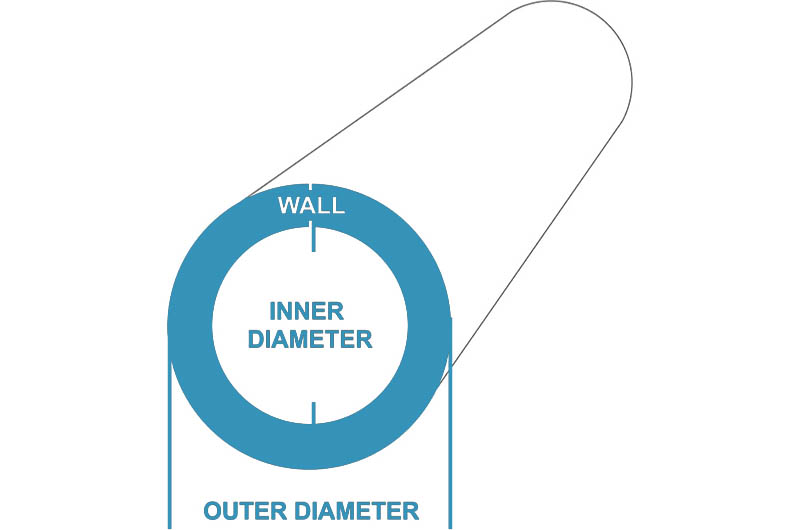

4.25" OD x 0.5" Wall x 3.25" ID Aluminum Round Tube 6061-T6511-Extruded

This 6061-T6511 aluminum round tube has an outer diameter of 4.25 inches, a wall thickness of 0.5 inches, and an inner diameter of 3.25 inches. Manufactured through extrusion, it is ideal for high-strength industrial frameworks, support structures, and large building projects.

This material meets the following specs: AMS -QQ-A-200/8, ASTM -B221, ASTM -B429

4.25" OD x 0.5" Wall x 3.25" ID Aluminum Round Tube 6061-T6511-Extruded Specifications

| Specification | Details |

| Outer Diameter | 4.25" |

| Wall Thickness | 0.5" |

| Inner Diameter | 3.25" |

| Material | Aluminum |

| Form | round tube |

| Alloy Type | 6061 |

| Max Length | 240 inches |

| Temper | T6511 |

| Production Method | Extruded |

4.25" OD x 0.5" Wall x 3.25" ID Aluminum Round Tube 6061-T6511-Extruded Features and Applications

Features:

- Strength: Suitable for high-stress structural applications.

- Corrosion Resistance: Excellent for outdoor and maritime environments.

- Machinability: Offers good machining properties for various industrial and manufacturing applications.

Applications:

- Aerospace: Used in aircraft structures, including wing spars and fuselage components.

- Construction: Employed in the building of support structures and scaffolding.

- Automotive: For chassis and framework components.

Aluminum alloy round tubes are made of 6061 aluminum alloy and are made through extrusion molding process, which meets the industry's requirements for lightweight, high strength, corrosion resistance and precision processing. The T6 and T6511 heat treatment states of 6061 give the product different advantages in strength, toughness and corrosion resistance, and can adapt to various complex engineering needs. Specific application scenarios include aerospace, automobile, construction, machinery and precision instruments.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- Custom cuts supported

6061 T6511 Aluminum Mechanical Properties

| Property | Value |

| Ultimate Tensile Strength KSI | 42 |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 40 |

| Brinell Hardness 500 kg load | 93 |

| Melting Point °F | 1080 - 1205 |

| Elongation % in 2 in. | 9 |

| Rockwell Hardness B Scale | 59 |

| Machinability % | 50 |

| Shear Strength KSI | 25 |

| Electrical Conductivity % IACS | 43 |

Chemistry Information 6061 Aluminum

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |