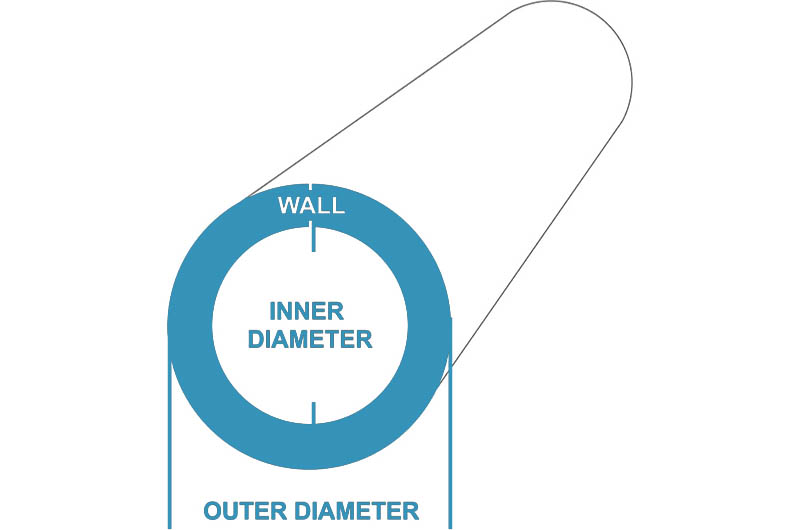

8" OD x 0.25" Wall x 7.5" ID Aluminum Round Tube 6061-T6-Extruded

This aluminum round tube is made from 6061-T6 aluminum alloy, extruded with an outer diameter of 8 inches, wall thickness of 0.25 inches, and inner diameter of 7.5 inches. The tube offers excellent corrosion resistance and strength, suitable for structural applications that require lightweight and high-strength materials, such as in the aerospace and automotive industries. The 6061-T6 temper provides enhanced tensile strength and good machinability, making it ideal for welding and surface treatments.

8" OD x 0.25" Wall x 7.5" ID Aluminum Round Tube 6061-T6-Extruded Specifications

| Specification | Details |

| Outer Diameter | 8" |

| Wall Thickness | 0.25" |

| Inner Diameter | 7.5" |

| Material | Aluminum |

| Form | round tube |

| Alloy Type | 6061 |

| Max Length | 288 inches (24 feet) |

| Temper | T6 |

| Production Method | Extruded |

8" OD x 0.25" Wall x 7.5" ID Aluminum Round Tube 6061-T6-Extruded More Informations

Features: The 6061-T6 aluminum alloy exhibits high tensile strength, corrosion resistance, and weldability. The tube is ideal for structural support and is capable of withstanding considerable loads. After T6 heat treatment, it demonstrates excellent fatigue resistance and pressure tolerance.

Applications:

- Building Structures: Used for support beams, bridge frames, and window frames.

- Vehicle Manufacturing: Suitable for automotive frames, chassis components, and structural parts.

- Aerospace: Used in aircraft structural components such as wing supports and fuselage frames.

Processing: Manufactured through extrusion, followed by T6 heat treatment to enhance strength and corrosion resistance. The material is weldable, making it suitable for secondary processing.

Aluminum round tubes are mostly made of 6061-T6 aluminum alloy, which provides excellent strength, corrosion resistance, processing performance and fatigue resistance in the T6 state after heat treatment. The extrusion molding process ensures that each tube has a consistent appearance, precise size and good mechanical properties suitable for various engineering requirements. It is suitable for many fields such as aviation, ships, automobiles, construction, machinery, etc.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- Custom cuts supported

6061 T6 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 40 |

| Brinell Hardness 500 kg load | 95 |

| Ultimate Tensile Strength KSI | 45 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 60 |

| Machinability % | 50 |

| Melting Point °F | 1080 - 1205 |

| Electrical Conductivity % IACS | 43 |

| Shear Strength KSI | 30 |

Chemistry Information 6061 Aluminum

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |